Color oil for ultra-high molecular weight polyethylene fiber and preparation method of color oil

A polyethylene fiber, ultra-high molecular weight technology, applied in the direction of single-component polyolefin rayon, fiber chemical characteristics, rayon manufacturing, etc., can solve the problem of easy pigment shedding, fiber color fastness, light fastness or washing fastness It can reduce the problems of lowering degree of color fastness and spinning roller pollution, and achieve the effect of high color fastness and washing resistance, avoiding falling off and migration, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

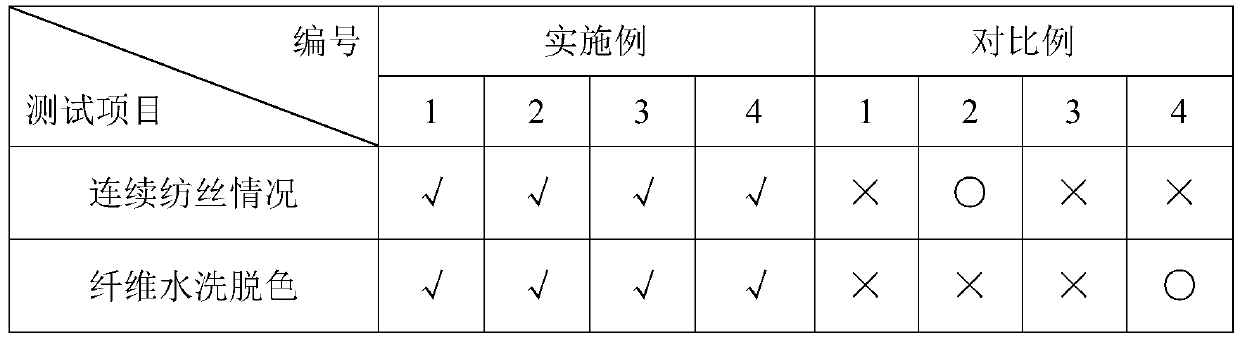

Examples

Embodiment 1

[0036] 100 parts of carbon black, 2 parts of γ-(methacryloyloxy)propyltrimethoxysilane and 5 parts Add ADP-1200 into a kneader, mix and modify at 70°C, and dry to obtain surface-modified carbon black.

[0037] Add 5 parts of polyacrylate to 200g of white oil, disperse at a speed of 1000r / min for 0.1h, add 100 parts of surface-modified carbon black, stir evenly, and place it for 24h for wetting; then perform high-speed dispersion, disperse The speed is 3000r / min, and the temperature is controlled at 60°C. Add 20 parts of free radical macromolecule A and 1 part of azobisisobutyronitrile dropwise, stir and react for 0.5h, and disperse with a grinder at a speed of 3600r / min. Disperse for 4 hours to make color oil for polyethylene fiber.

Embodiment 2

[0039] 40 parts of Pigment Red 255, 1.2 parts of γ-(methacryloyloxy)propyltrimethoxysilane and 3.2 parts Add ADP-1230 into a kneader, mix and modify at 50°C, and dry to obtain surface-modified Pigment Red 255.

[0040]Add 6 parts of polypyrrole to 200g of decahydronaphthalene, disperse at a speed of 3000r / min for 0.5h, add 40 parts of surface-modified Pigment Red 255, stir evenly, and place it for 24h for wetting; then perform high-speed dispersion, The dispersion speed is 6000r / min, and the temperature is controlled at 120°C. Add 27 parts of free radical macromolecule B and 0.2 parts of azobisisoheptanonitrile dropwise, stir and react for 1 hour, and then disperse with a high-speed disperser at 4000r / min Rotate to disperse for 4 hours to make color oil for polyethylene fiber.

Embodiment 3

[0042] 70 parts of Pigment Red 121, 0.7 parts of γ-aminopropyltriethoxysilane and 0.7 parts Add ADP-1200 into a kneader, mix and modify at 80°C, and dry to obtain surface-modified Pigment Red 121.

[0043] Add 7 parts of polypyrrolidone to 200 parts of C 15 In isoparaffins, after dispersing for 1 hour at a speed of 3000r / min, add 70 parts of surface-modified pigment red 121 to stir evenly, and place it for 48 hours for wetting; then carry out high-speed dispersion at a speed of 4000r / min, And control the temperature at 120°C, add 1 part of free radical macromolecule C and 0.1 part of benzoyl peroxide dropwise, stir and react for 2 hours, disperse with a ball mill, and disperse at a speed of 5000r / min for 4 hours to make polyethylene fibers Use color oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com