High-content sodium alginate nanofiber membrane and electrostatic spinning manufacturing method thereof

A technology of nanofiber membrane and sodium alginate, which is applied in fiber treatment, textile and papermaking, filament/thread forming, etc., and can solve the problems of limiting nanofiber membrane performance, nanofiber membrane reagent residue, and low sodium alginate content , to achieve low cytotoxicity, improve spinning conditions, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

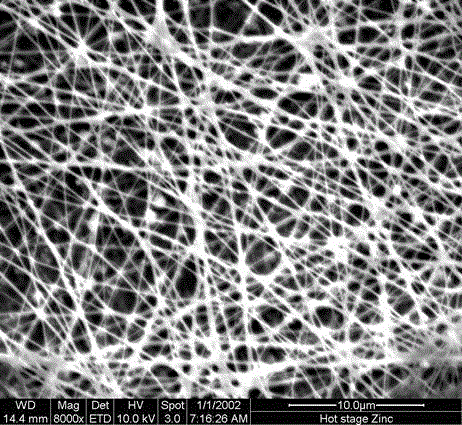

Image

Examples

Embodiment 1

[0021] (1) Preparation of spinning solution: Dissolve a certain amount of sodium alginate in deionized water and stir evenly at room temperature to prepare a sodium alginate solution with a mass fraction of 3wt%. Dissolve a certain amount of polyethylene oxide in deionized water Stir evenly at room temperature to prepare a polyethylene oxide solution with a mass fraction of 3wt%, dissolve a certain amount of polyvinyl alcohol solution in deionized water and stir evenly at 90°C to prepare a polyvinyl alcohol solution with a mass fraction of 8wt%; then Sodium alginate solution, polyethylene oxide solution and polyvinyl alcohol solution were mixed at a mass ratio of 4:4:2, stirred evenly at room temperature to obtain a homogeneous mixed solution, and then TX- 100 Stir evenly at room temperature to obtain an electrospinning solution;

[0022] (2) Preparation of composite nanofiber membrane: The electrospinning solution prepared in step (1) was left to stand at room temperature for...

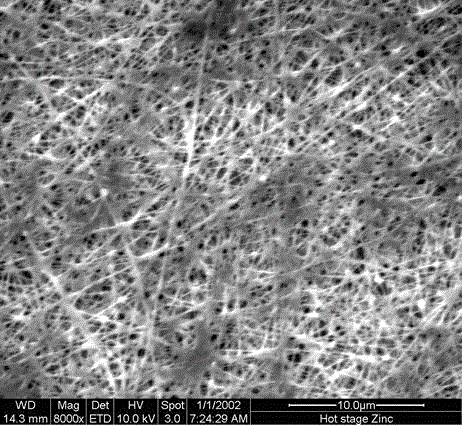

Embodiment 2

[0025] (1) Preparation of spinning solution: Dissolve a certain amount of sodium alginate in deionized water and stir evenly at room temperature to prepare a sodium alginate solution with a mass fraction of 3wt%. Dissolve a certain amount of polyethylene oxide in deionized water Stir uniformly at room temperature to prepare a polyethylene oxide solution with a mass fraction of 3 wt%, dissolve a certain amount of polyvinyl alcohol solution in deionized water and stir at 90°C to prepare a polyvinyl alcohol solution with a mass fraction of 8 wt%. Then sodium alginate solution, polyethylene oxide solution and polyvinyl alcohol solution are mixed in a mass ratio of 5:4:1, stirred evenly at room temperature to obtain a homogeneous mixed solution, and then added to the homogeneous mixed solution with a mass fraction of 1wt% TX -100 Stir evenly at room temperature to obtain the electrospinning solution;

[0026](2) Preparation of composite nanofiber membrane: The electrospinning solut...

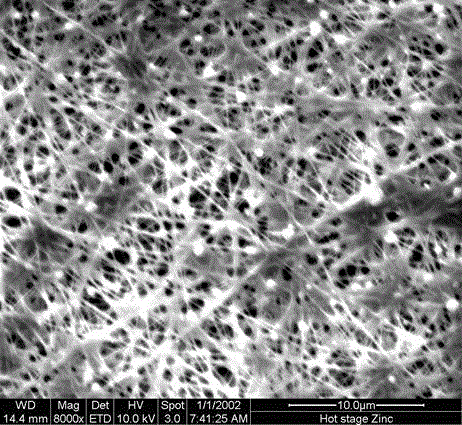

Embodiment 3

[0029] (1) Preparation of spinning solution: Dissolve a certain amount of sodium alginate in deionized water and stir evenly at room temperature to prepare a sodium alginate solution with a mass fraction of 3wt%. Dissolve a certain amount of polyethylene oxide in deionized water Stir uniformly at room temperature to prepare a polyethylene oxide solution with a mass fraction of 3 wt%. Then mix the sodium alginate solution and the polyethylene oxide solution at a mass ratio of 5:5, stir at room temperature to obtain a homogeneous mixed solution, then add TX-100 with a mass fraction of 1.5wt% to the homogeneous mixed solution and stir at room temperature Uniform electrospinning solution;

[0030] (2) Preparation of composite nanofiber membrane: The electrospinning solution prepared in step (1) was left to stand at room temperature for 24 hours to remove air bubbles, and then the spinning solution was injected into the needle tube of the electrospinning device and connected to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com