Superfine elastic non-woven fabric and preparation method thereof

A non-woven fabric and elastic technology, applied in the field of ultra-fine elastic non-woven fabric and its preparation, can solve the problems of discontinuous fiber, poor fiber performance, low production efficiency, etc., to avoid uneven fiber diameter and overcome viscosity Effect of surface tension and fine fiber diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for preparing ultrafine elastic non-woven fabrics based on a planar receiving centrifugal spinning device, comprising the following steps:

[0054] S1. Preparation of spinning solution: dissolving polyurethane particles in N,N-dimethylformamide, stirring evenly, and vacuum defoaming to prepare spinning solution; wherein, the polyurethane particles and N,N-dimethylformamide The amide mass fraction ratio is 20%:80%, the stirring temperature is 20-45°C, the stirring rate is 520r / min, the stirring time is 2h, and the vacuum defoaming treatment time is 30min;

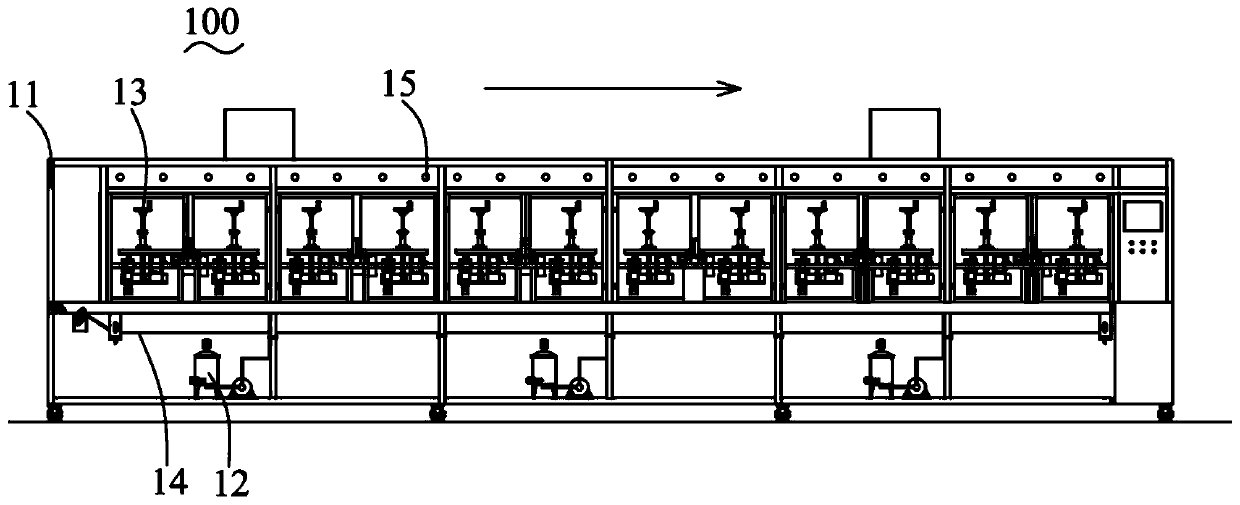

[0055] S2. Centrifugal spinning: inject the spinning solution prepared in step S1 into a plane receiving centrifugal spinning device 100 for centrifugal spinning to obtain ultrafine elastic nonwoven fabrics; wherein, the centrifugal spinning parameters are as follows: the spinning The spinneret aperture of device is 0.16mm (needle specification used is 30G), and the rotating speed of spinneret is 5000r / min, a...

Embodiment 2-7

[0058] Embodiment 2-7 provides the method for preparing superfine elastic non-woven fabric based on the planar receiving type centrifugal spinning device, compared with embodiment 1, its difference is that the polyurethane particles and N, N-dimethyl formaldehyde The mass fraction ratio of amide, other steps are basically the same as those in Example 1, and are not described in detail here; the mass fraction ratio of polyurethane and N, N-dimethylformamide is shown in the following table in Examples 2-7:

[0059] project Mass fraction ratio of polyurethane to N,N-dimethylformamide Example 2 21%:79% Example 3 22%:78% Example 4 23%:77% Example 5 30%:70% Example 6 40%:60% Example 7 50%:50%

[0060] Table 1 is the performance of the ultrafine elastic non-woven fabric prepared by embodiment 1-7

[0061]

[0062] From table 1 and Figure 5 to Figure 11 It can be seen that when the mass fraction ratio of polyurethane and N,N-dim...

Embodiment 8-14

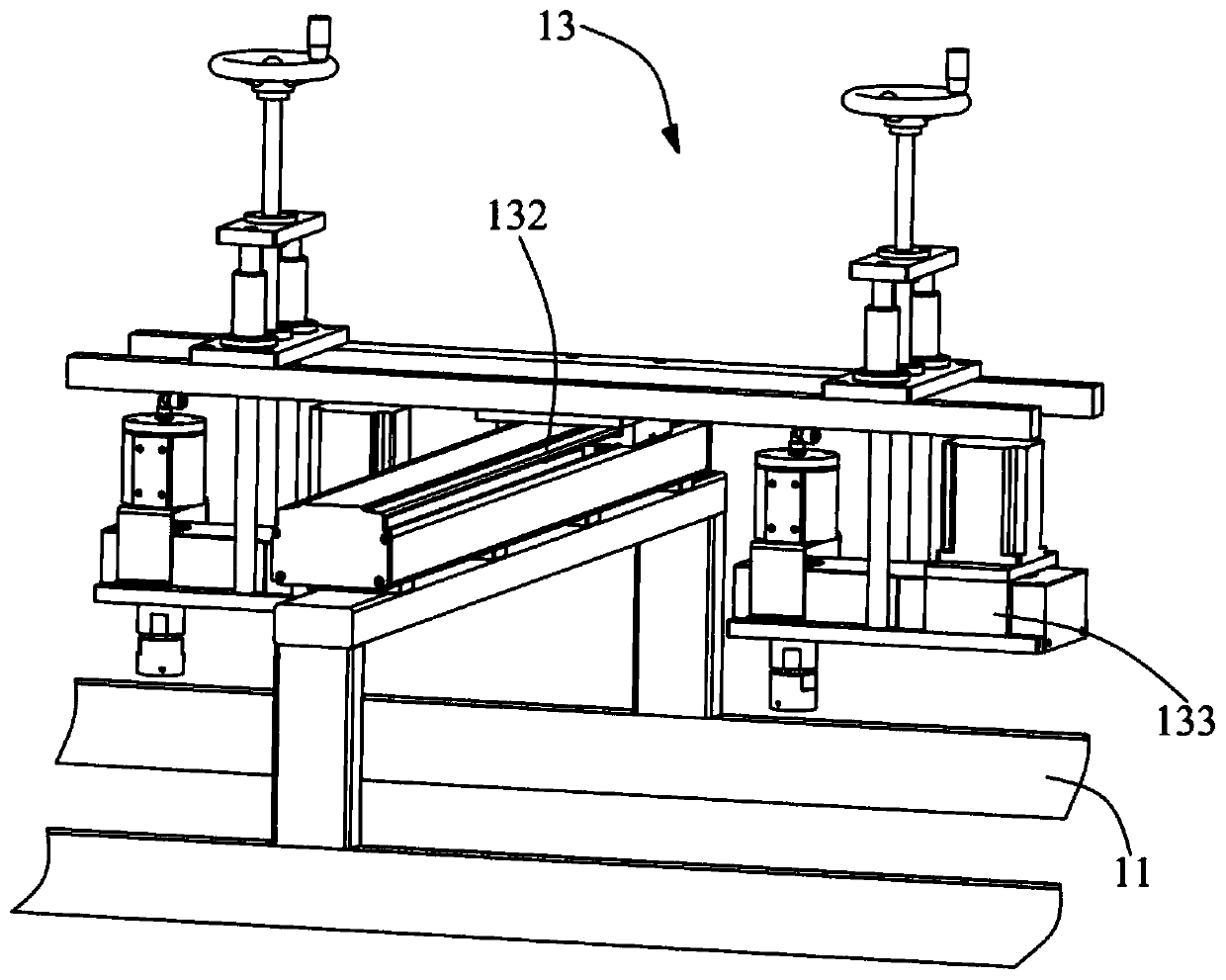

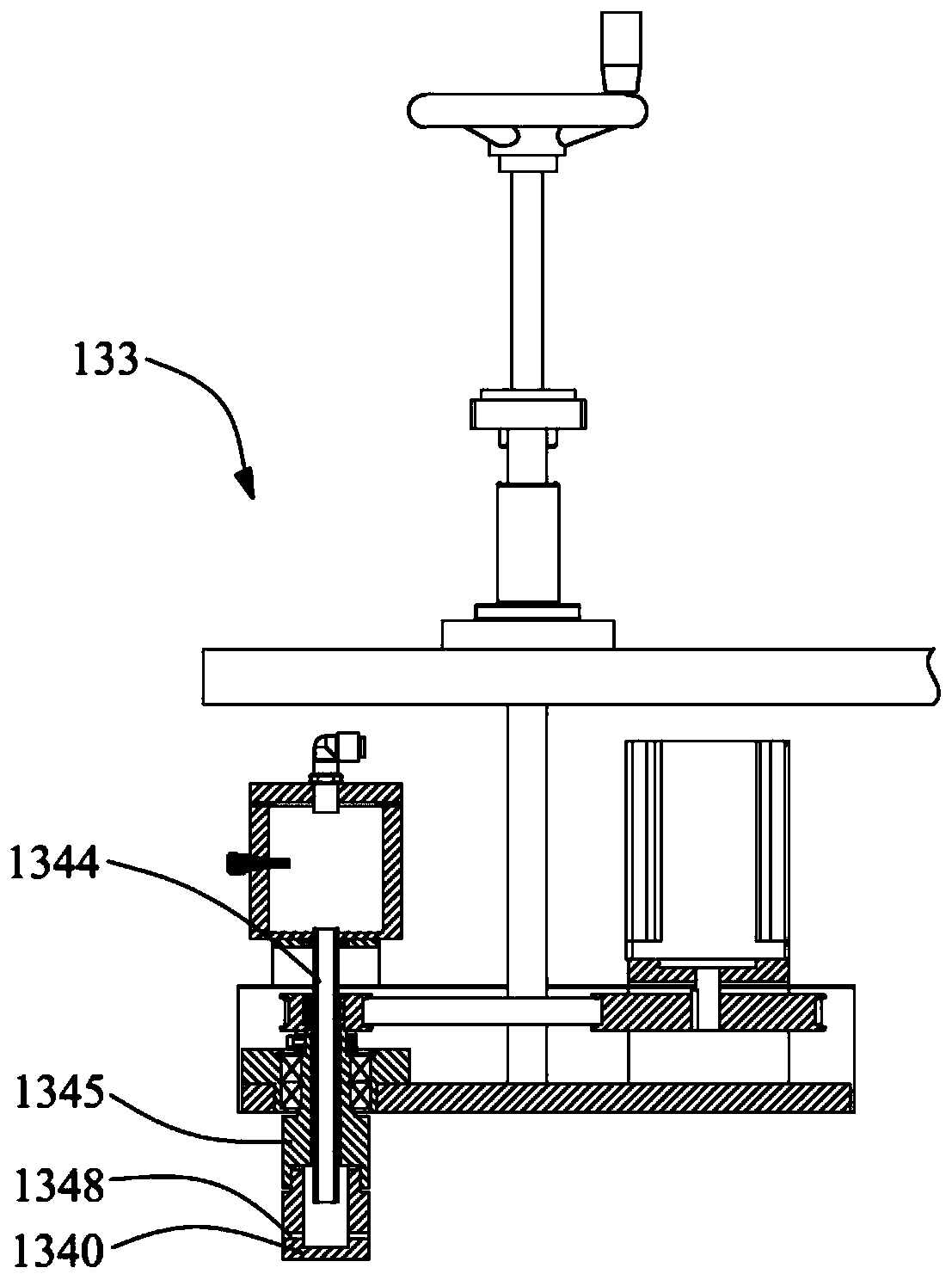

[0065] Embodiment 8-14 provides the method for preparing superfine elastic non-woven fabric based on the planar receiving type centrifugal spinning device, compared with embodiment 2, its difference is that the collection device 14 and the spinneret device are changed The spinning distance between 133, other steps are basically the same as in Example 2, and are not repeated here; the spinning distance in Examples 8-14 and the mechanical properties of the prepared ultrafine elastic nonwoven fabric are shown in Table 2 Show:

[0066] Table 2 is the spinning distance of Examples 2 and 8-14 and the mechanical properties of the prepared ultrafine elastic nonwoven fabric

[0067]

[0068] As can be seen from Table 2, as the spinning distance increases, the fiber diameter gradually decreases due to the fact that the fiber can be drawn more effectively within the same time period. When the spinning distance is 5 cm (Example 9), the prepared The diameter of ultra-fine elastic non-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com