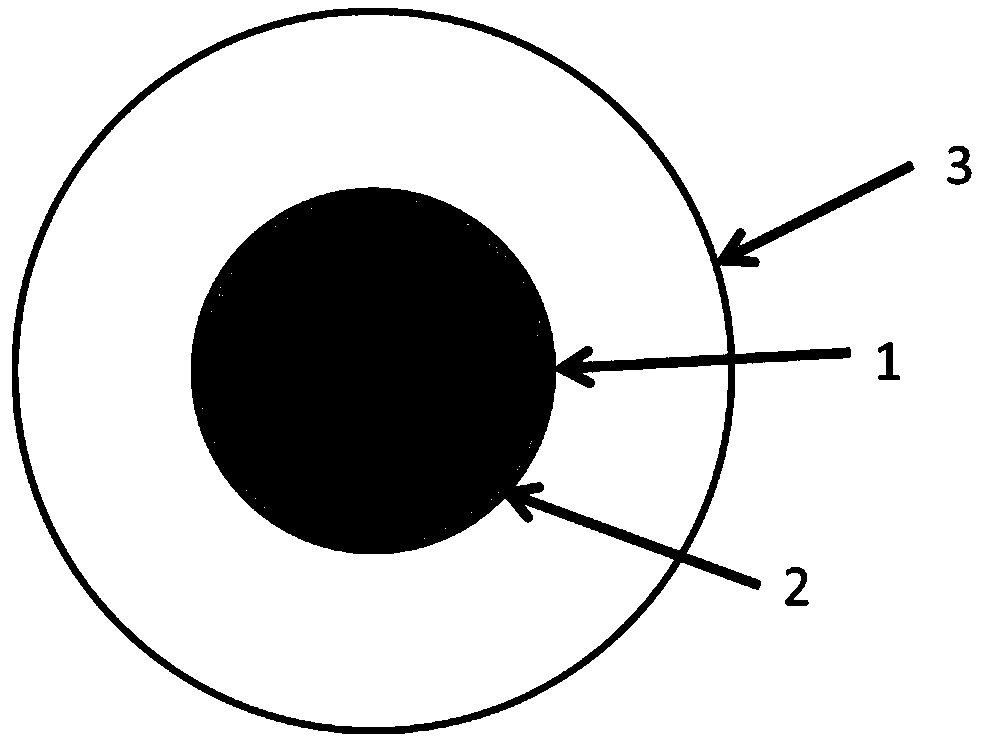

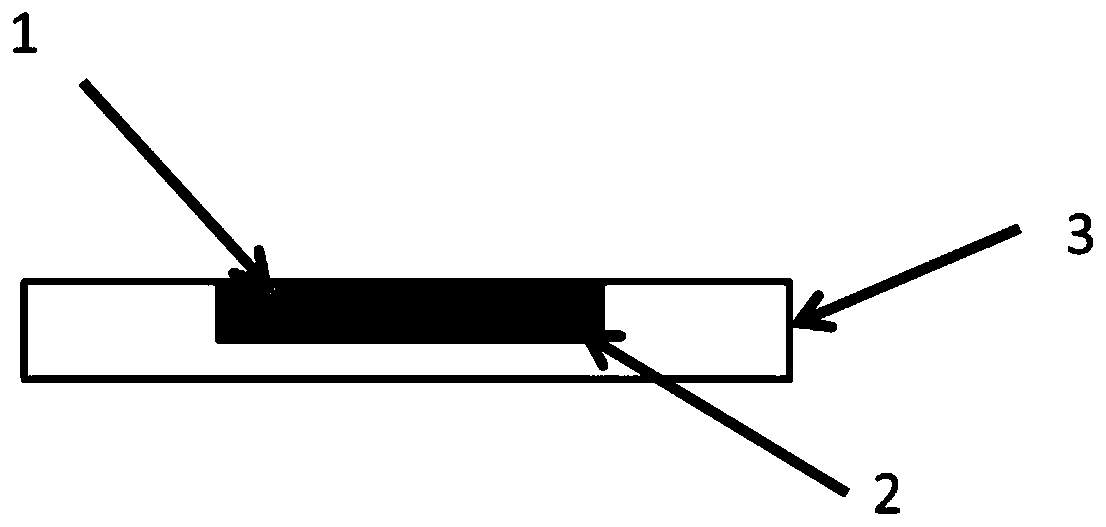

Double-layer composite drug-loading adhering patch and preparation method and application thereof

A double-layer compounding and medicament technology, which is applied in the field of medical and biomedical materials, can solve the problems of single effect and the inability to form a gradient release of drugs, and achieve the effects of preventing infection, promoting rapid healing, and good treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

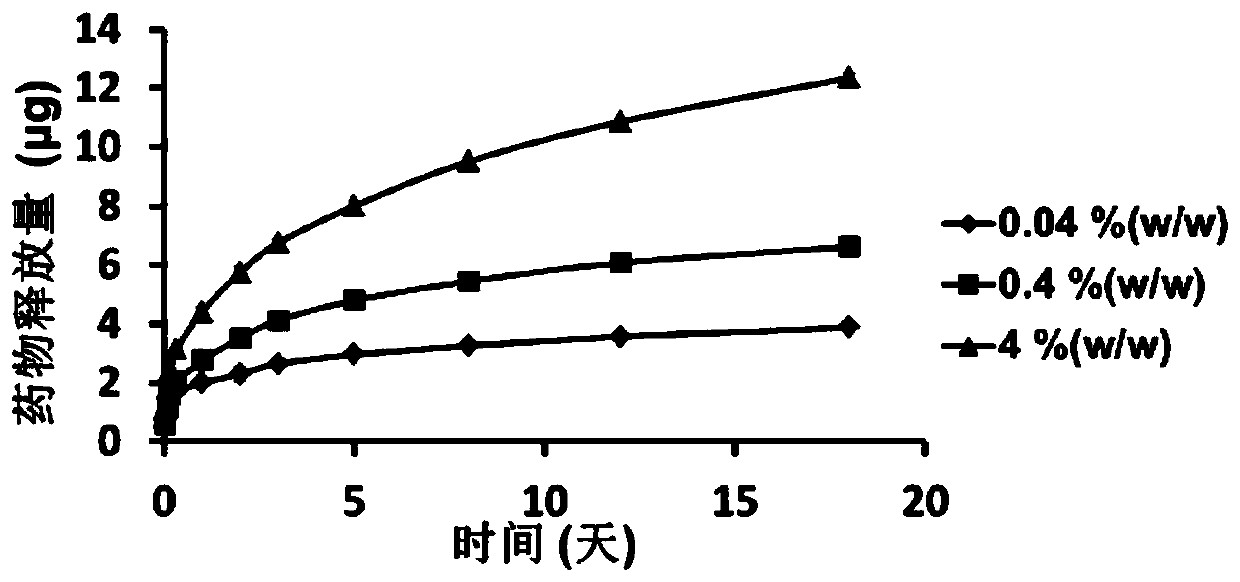

Embodiment 1

[0045] Step 1: Weigh 1 part of diclofenac sodium and 3 parts of polyethylene oxide and add it to 1800 parts of deionized water, stir on a magnetic stirrer for 24 hours until the mixture becomes a uniform milky white solution, and use it as a spinning solution for burst drug release; weigh Add 0.1 part of curcumin and 10 parts of L-polylactic acid to 100 parts of hexafluoroisopropanol, stir on a magnetic stirrer for 24 hours until the mixture becomes a uniform and transparent yellow solution, and use it as a slow-release drug spinning solution for use;

[0046] Mix 0.001g of hydroxypropyl methylcellulose, 0.01ml of propylene glycol and 0.1ml of deionized water in a syringe to form a homogeneous solution, place it on a centrifuge and centrifuge once at a speed of 1000r / min, remove the bubbles in the solution, and inject plastic The round hole of the silicone mold is ready for use, and the thickness of the mold is 0.5mm.

[0047] Step 2: Under the working environment of 15°C and ...

Embodiment 2

[0051] Step 1: Weigh 5 parts of diclofenac sodium and 20 parts of polyethylene oxide and add them to 3500 parts of deionized water, stir on a magnetic stirrer for 24 hours until the mixture turns into a uniform milky white solution, and use it as a burst drug spinning solution for use; weigh Add 10 parts of curcumin and 100 parts of L-polylactic acid to 500 parts of hexafluoroisopropanol, stir on a magnetic stirrer for 24 hours until the mixture becomes a uniform and transparent yellow solution, and use it as a slow-release drug spinning solution;

[0052] Mix 1g of hydroxypropyl methylcellulose, 1ml of propylene glycol and 5ml of deionized water in a syringe to form a homogeneous solution, place it on a centrifuge and centrifuge 5 times at a speed of 8000r / min, remove the bubbles in the solution, and inject it into a plastic silicone mold. Stand-by in the round hole, the thickness of the mold is 3mm.

[0053] Step 2: Under the working environment of 30°C and 60% relative humi...

Embodiment 3

[0057] Step 1: Weigh 3 parts of diclofenac sodium and 12 parts of polyethylene oxide and add them to 2200 parts of deionized water, stir on a magnetic stirrer for 24 hours until the mixture becomes a uniform milky white solution, and use it as a burst release drug spinning solution for use; weigh Add 3 parts of curcumin and 50 parts of L-polylactic acid to 300 parts of hexafluoroisopropanol, stir on a magnetic stirrer for 24 hours until the mixture becomes a uniform and transparent yellow solution, and use it as a slow-release drug spinning solution;

[0058] Mix 0.1g hydroxypropyl methylcellulose, 1ml propylene glycol and 1ml deionized water in a syringe to form a homogeneous solution, place it on a centrifuge and centrifuge 3 times at a speed of 3000r / min, remove the bubbles in the solution and inject it into a plastic silicone mold The round hole is ready for use, and the thickness of the mold is 1.5mm.

[0059] Step 2: Under the working environment of 20°C and 40% relative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com