A preparation method of monolithic polyacrylonitrile carbon fiber electrode for desalination

A polyacrylonitrile and polyacrylonitrile membrane technology, which is applied in separation methods, electrochemical water/sewage treatment, dispersed particle separation, etc., can solve the problems of large-scale preparation of carbon materials that are difficult to achieve, and the process is tedious, and achieves thin fiber diameters. , the effect of high desalination capacity and strong desalination capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below by example the present invention will be further described

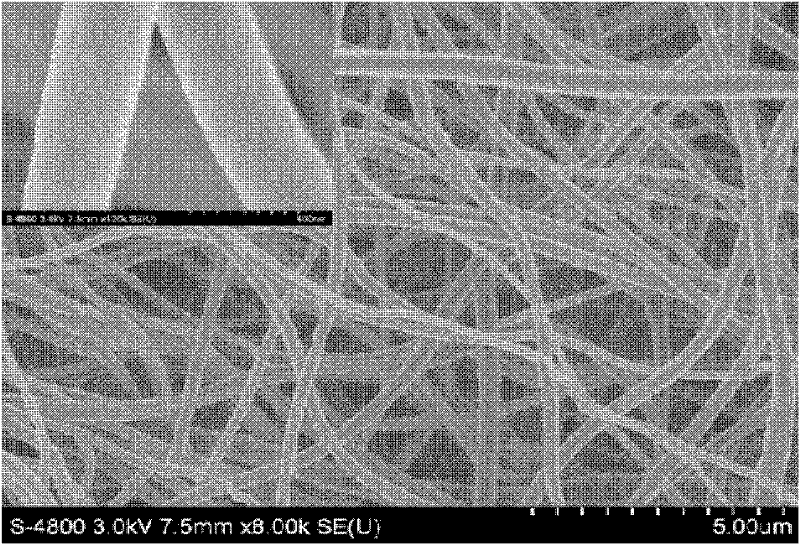

[0026] This example prepares polyacrylonitrile fiber film ( figure 1 ), and then investigate the properties of carbon fibers at different activation temperatures (750, 800, and 900 °C). The specific properties are shown in Table 1. It can be seen from Table 1 that the specific surface area increases with the increase of activation temperature; when the activation temperature is 900 °C, the specific surface area is 712m 2 / g. In addition, the average pore size of carbon fiber is more than 2nm, so it contains abundant mesopores, which is beneficial to the adsorption of salt, because mesopores are more conducive to the electrosorption of hydrated sodium ions and hydrated chloride ions.

[0027] Table 1 Pore performance characteristics of monolithic activated PAN-based carbon fiber

[0028]

[0029] figure 2 When the activation temperature is 900 ° C, PAN-based activated carbon fibers. From figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com