Preparation method for spring-like fiber bundle with high strength and high elasticity

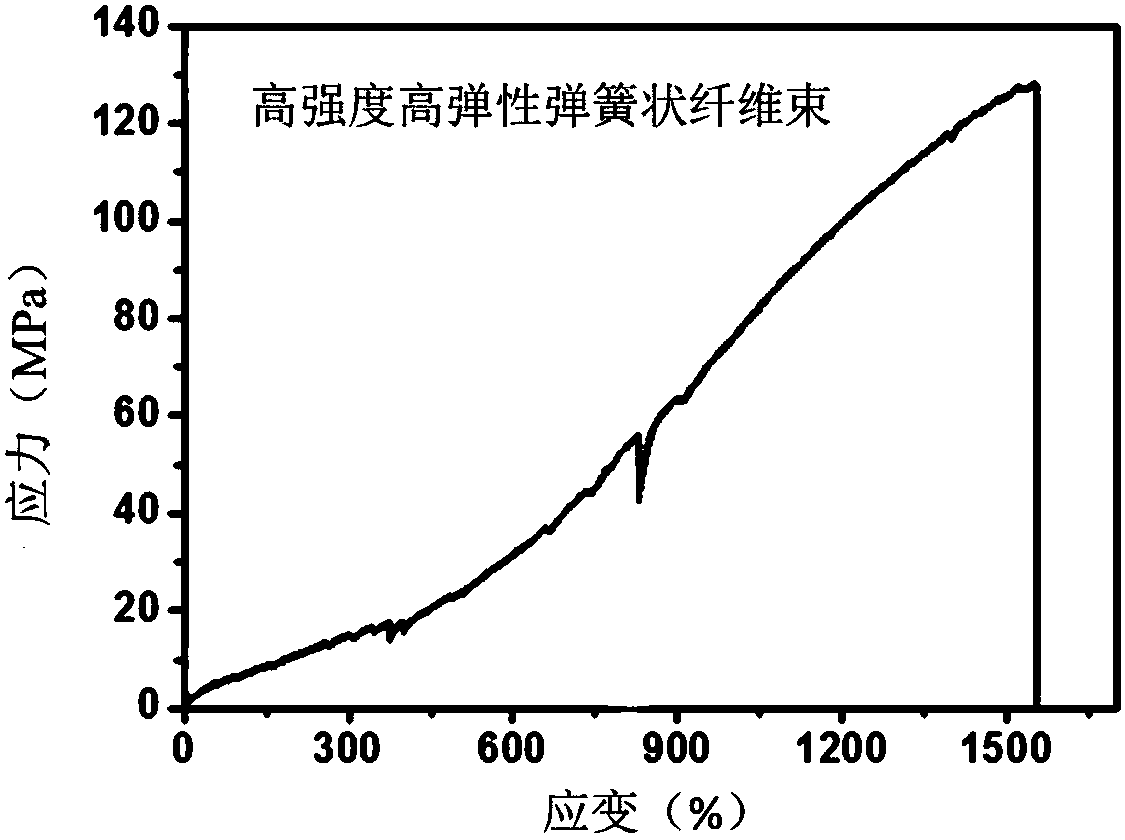

A spring-like, fiber bundle technology, applied in the field of chemical engineering, can solve the problems of insufficient tensile properties of spring-like fiber bundles, and achieve the effects of controllable size and mechanical properties, good stretchability, and simple and easy-to-control methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

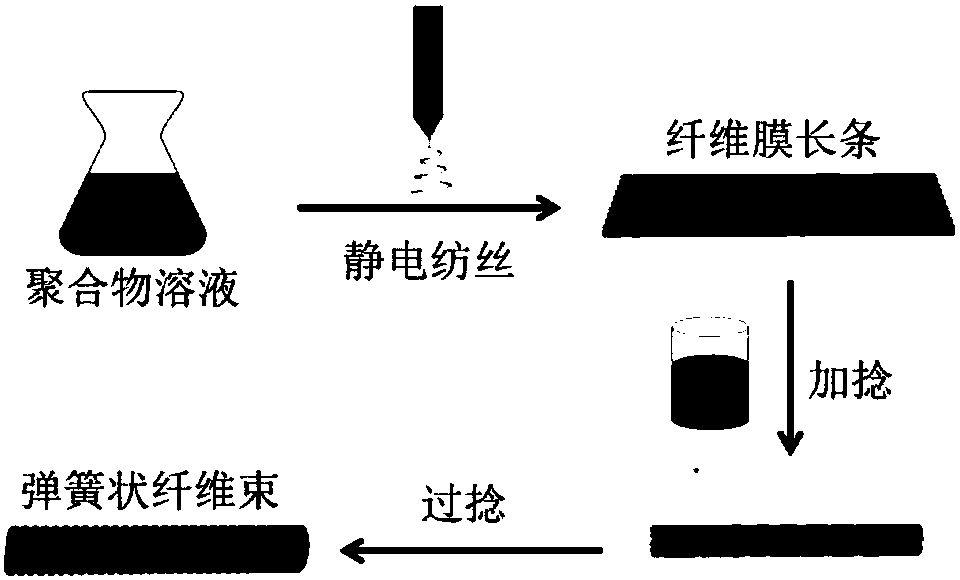

[0029] Configure the PA66 precursor solution, the solvent is acetic acid, the mass percentage concentration is 10%, and electrospinning is carried out, the working voltage is 10kV, the spinning distance is 20cm, the rotating speed of the drum is 3000 turns / min, and the diameter of a single fiber is obtained after 1 hour. The 50nm fiber membrane is cut into strips with a length of 5 cm and a width of 1 cm. Fix the two ends of the long bar on the translation platform and the electric motor respectively. Before twisting, use a 2mL syringe to drop 0.5mL of plasticizer ethanol onto the long bar. For twisting, the rotation speed of the electric motor during twisting is 200 turns / min, and the twisting time is 1s; then over-twisting, the rotation speed of the electric motor is the same as that of twisting, and the advancing speed is 5cm / min. The specific operation process is as attached figure 1 As shown, until the formation of a complete helical structure stops, a high-strength and h...

Embodiment 2

[0031] Configure the PVDF precursor solution, the solvent is acetone and N,N dimethylacetamide (DMAc) with a volume ratio of 3:7, the mass percentage concentration is 20%, and the electrospinning is carried out, the working voltage is 13kV, and the spinning distance is 20 cm, the rotating speed of the drum is 50 turns / min, after 50 minutes, a fiber membrane with a single fiber diameter of 2 μm is obtained, which is cut into strips with a length of 100 cm and a width of 10 cm. Fix the two ends of the strip on the translation platform and the electric motor respectively. During and after twisting, use a 2mL syringe to drop the plasticizer DMF on the strip twice, 1mL each time, and then Twisting is carried out during the process of DMF volatilization. During the twisting process, the electric motor rotates at a speed of 100 turns / min, and the twisting time is 30s. The complete helical structure stops, and a high-strength and highly elastic spring-like fiber bundle with a diameter...

Embodiment 3

[0033] Configure the PAN precursor solution, the solvent is acetone and N,N dimethylformamide (DMF) with a mass ratio of 1:1, the mass percentage concentration is 10%, and electrospinning is carried out, the working voltage is 15kV, and the spinning distance is 15cm, the rotating speed of the drum is 1000turns / min, after 30 minutes, a fiber film with a single fiber diameter of 200nm is obtained, which is cut into strips with a length of 20cm and a width of 2cm. Fix the two ends of the strip on the translation platform and the electric motor respectively. Before twisting and after twisting, use a 2mL syringe to drop the plasticizer acetone on the strip three times, 2mL each time, and then Twisting is carried out in the process of acetone volatilization, and the rotating speed of electric motor is 500turns / min in twisting process, and twisting time is 50s; Form a complete helical structure and stop to obtain a high-strength and highly elastic spring-like fiber bundle with a diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com