Preparation method of shear thickening liquid

A technology for thickening liquids and emulsions, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of easy agglomeration, instability, and difficulty in the preparation of STF liquids of nanoparticles, and achieve the effect of simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

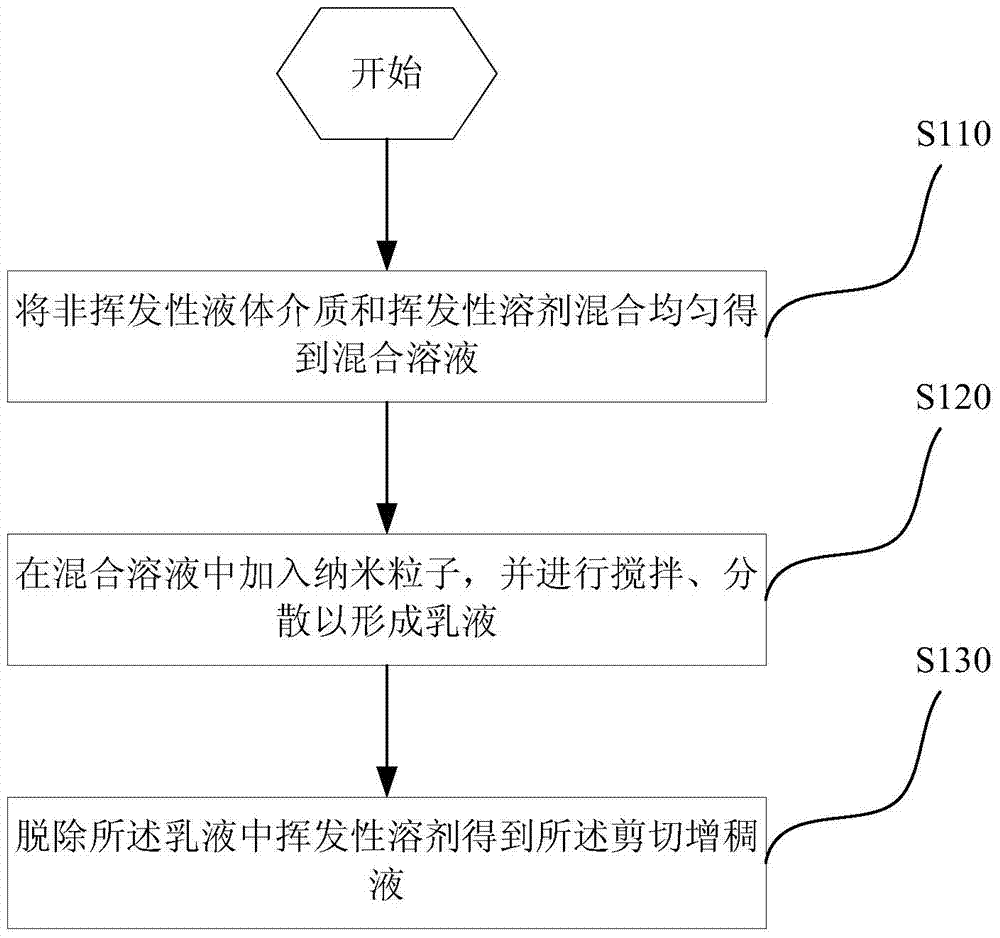

[0024] see figure 1 , figure 1 The flow chart of the steps of the method 100 for preparing the shear thickening liquid provided by the embodiment of the present invention includes:

[0025] Step S110: uniformly mixing the non-volatile liquid medium and the volatile solvent to obtain a mixed solution;

[0026] Preferably, the mass ratio of the non-volatile liquid medium to the volatile solvent is between 1 / 2˜1 / 6.

[0027] Preferably, the non-volatile liquid medium is at least one of ethylene glycol and polyethylene glycol.

[0028] Preferably, the volatile solvent is at least one of ethanol and ethyl acetate.

[0029] Specifically, the non-volatile liquid medium and the volatile solvent are uniformly mixed according to the above mass ratio in a container equipped with stirring and ultrasonic equipment to obtain the above mixed solution.

[0030] Step S120: adding nanoparticles into the mixed solution, stirring and dispersing to form an emulsion;

[0031] Preferably, the na...

Embodiment

[0040] Quantitatively take 600g of ethylene glycol and 1200g of ethanol into a 3L container and stir and mix evenly; weigh 1300g of nano-silica particles, add them to the above mixed solution under stirring and ultrasonication, stir and ultrasonically disperse for 1-2 hours until a uniform white Emulsion; move the above emulsion to a container with a vacuum system, remove the volatile solvent in vacuum for about 2-4 hours until no bubbles are generated; turn off the vacuum system, break the vacuum to normal pressure, and obtain the shear thickening of the designed composition Liquid, it can be understood that by changing the quality of ethylene glycol, ethanol and nano-silica particles, the above method can be used to prepare shear-thickening liquids with various proportions and high solid content.

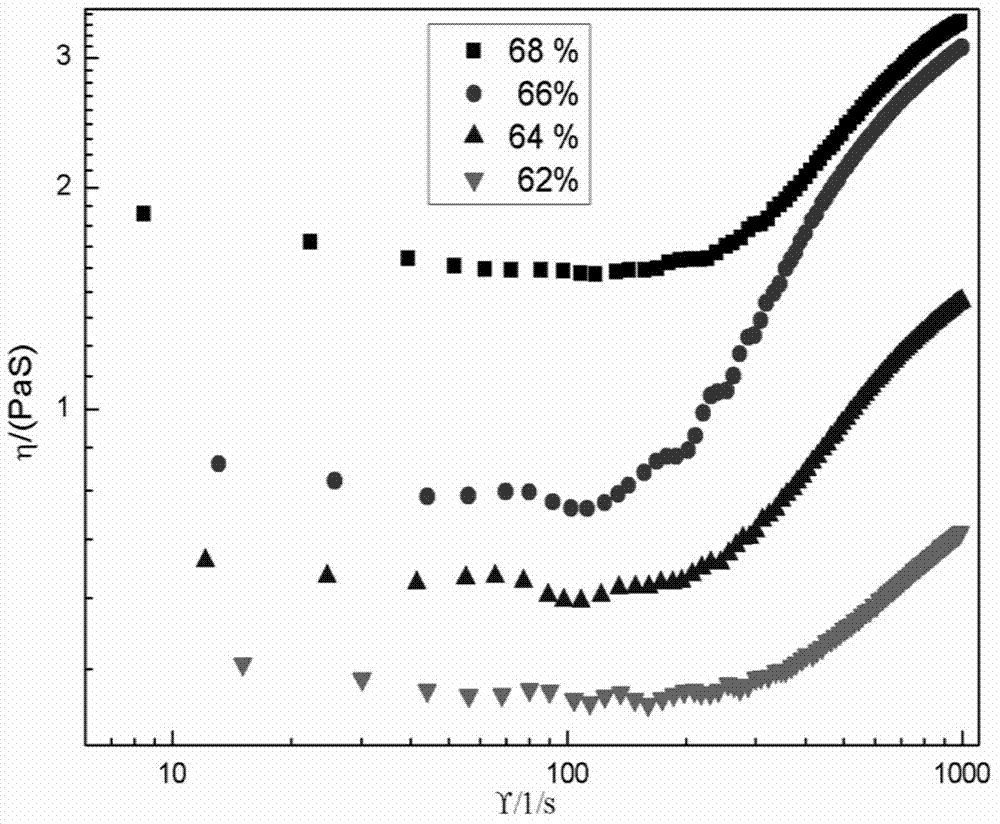

[0041] see figure 2 , is the rheological characteristic curve graph of the STF liquid of each solid phase content that the present embodiment prepares, from figure 2 It can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com