Process for production of fucoxanthin, and microalga for use in the process

A technology of fucoxanthin and microalgae, applied in single-cell algae, fermentation, etc., can solve the problems of low productivity, unfavorable preparation cost, difficult to handle scutellaria, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention relates to a method for producing fucoxanthin, which comprises culturing microalgae having a fucoxanthin productivity of 0.5 mg / liter / day or more in a culture medium and isolating and extracting fucoxanthin from the cultured algae.

[0036] The importance of productivity of 0.5 mg / L / day or more

[0037] Microalgae are known to produce fucoxanthin. Fucoxanthin is known as an auxiliary dye with convergence for photosynthesis. However, no examples of research work on the detailed examination of fucoxanthin levels in microalgae are known. Therefore, it is completely unknown how much fucoxanthin is contained therein ("Carotenoid" edited by Shinichi Takaichi, April 2006, pp. 10-48).

[0038] Harvesting fucoxanthin from seaweed involves competition with food, difficult recovery, stable preparation, harsh extraction (presence of polysaccharides), etc. For example, in the case of crocodile buds, the productivity of fucoxanthin was about 0.01 mg / liter / day...

Embodiment 1

[0051] Microalgae of Chrysophyceae

[0052] Ochromonas danica CS-4 strain of Chrysophyceae (available from Microbial Culture Collection, the National Institute for Environmental Studies) was cultured in JM medium (Table 1). The strain was grown at 300 μmol m in 200 ml of JM medium -2 S -1 (14-hour light cycle and 10-hour dark cycle) were cultured for 7 days, and the JM medium was filled into a 500-ml Erlenmeyer flask in a constant temperature water tank at 25°C.

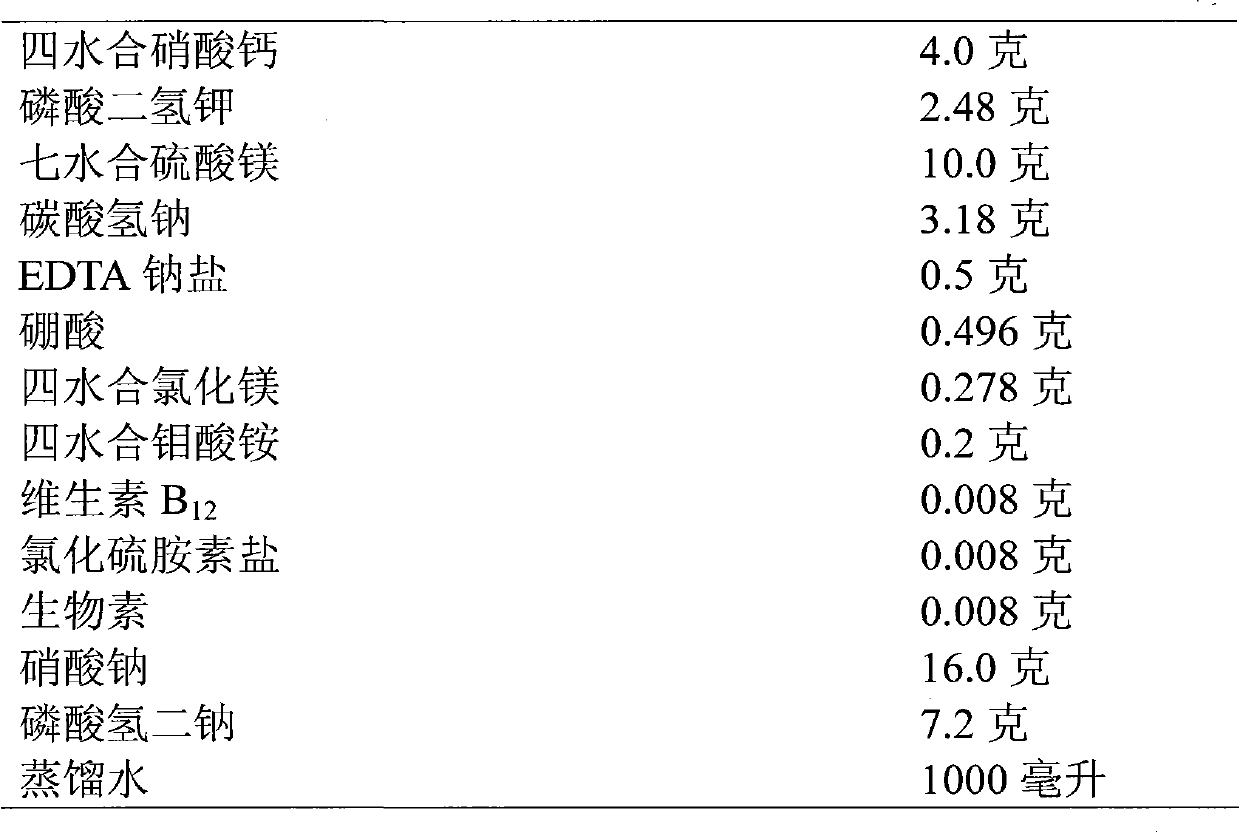

[0053] Table 1

[0054]

Embodiment 2

[0056] Cultivation of Microalgae of the Bromeliaceae

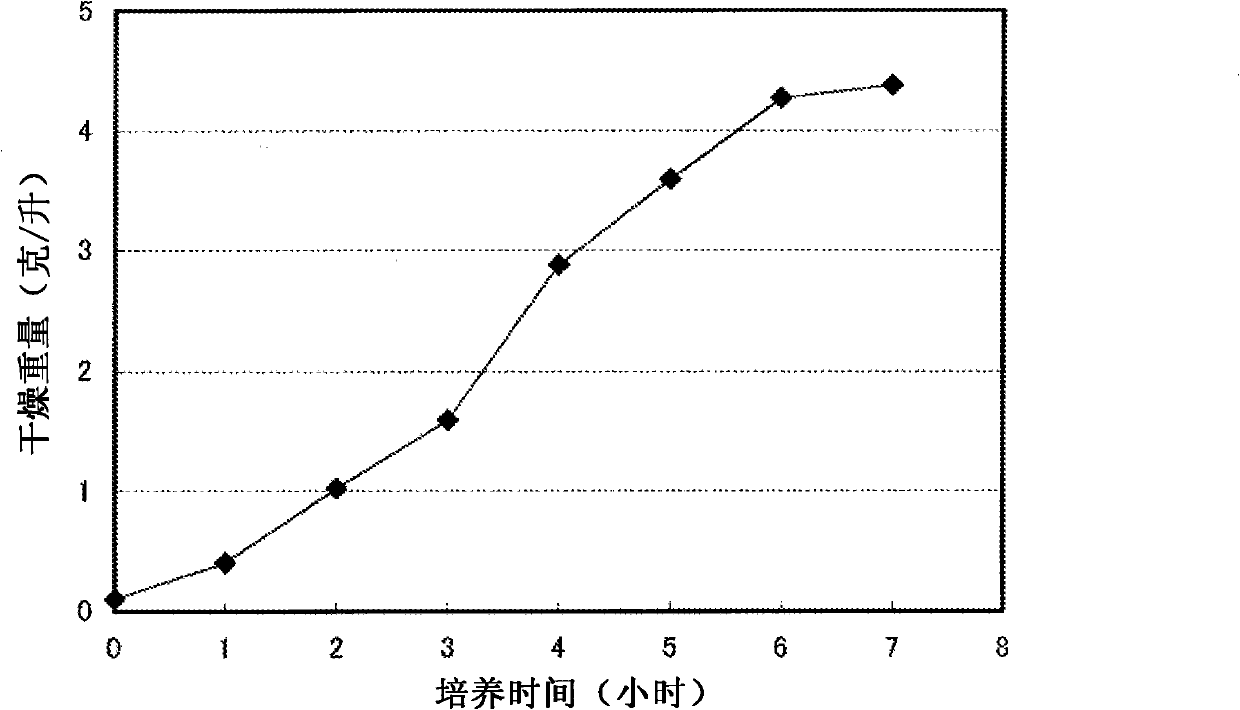

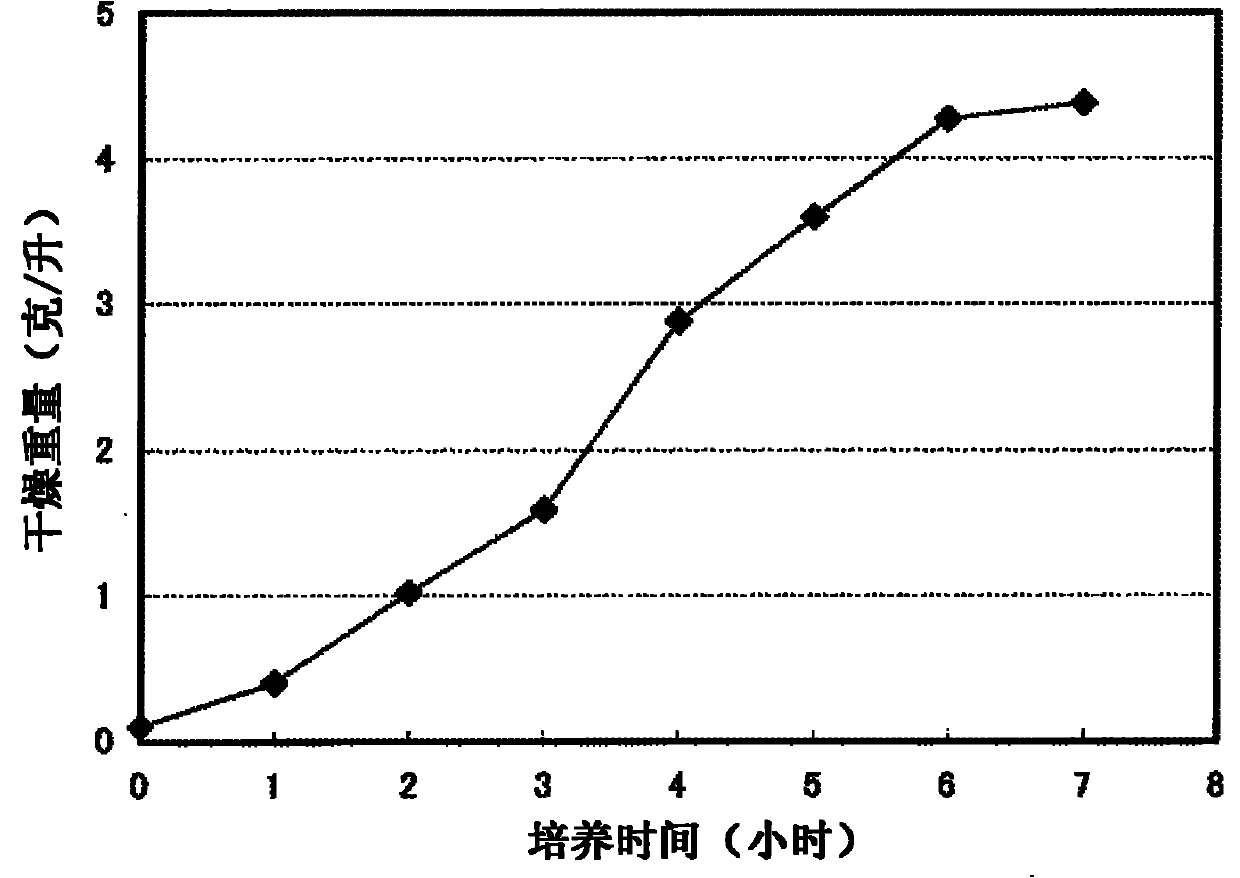

[0057] Pinguiochrysis pyriformis MBIC 10782 strain of Pineappleellaceae (commercially available from Marine Biotechnology Research Institute) was cultured in IMK medium (Table 2). The strain was cultured in 100 ml of IMK medium filled into a 500 ml Erlenmeyer flask capped with Silicosen (manufactured by Shin-Etsu Polymer Co., Ltd.). A 1 ml glass pipette was passed through the Silicosen and the tube was stirred with aeration from its bottom. Cultured in a constant temperature water tank at 25 °C and under aerated conditions at pH control and 300 μmol m -2 S -1 (continuous irradiation) for 7 days. The evolution of the culture over time is shown in figure 1 .

[0058] Table 2

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com