Preparation method of high-crystallization graphene quantum dots capable of replacing fullerene

A technology of graphene quantum dots and high crystallinity, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as expensive and difficult to achieve large-scale production, and achieve high Effect of carbon content, realization of large-scale production, and high crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

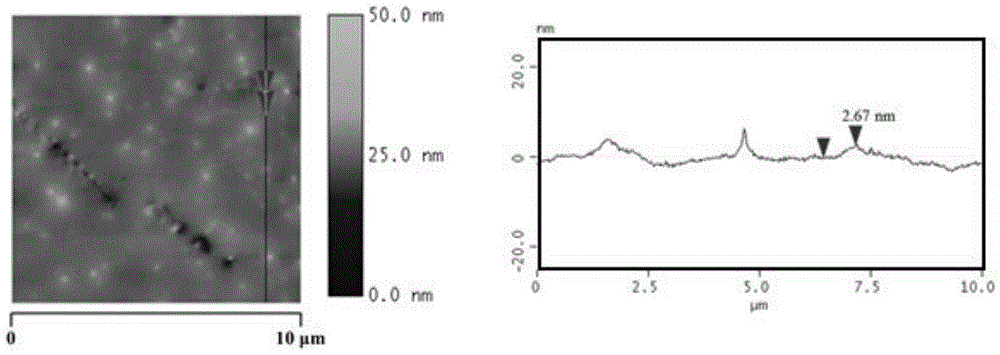

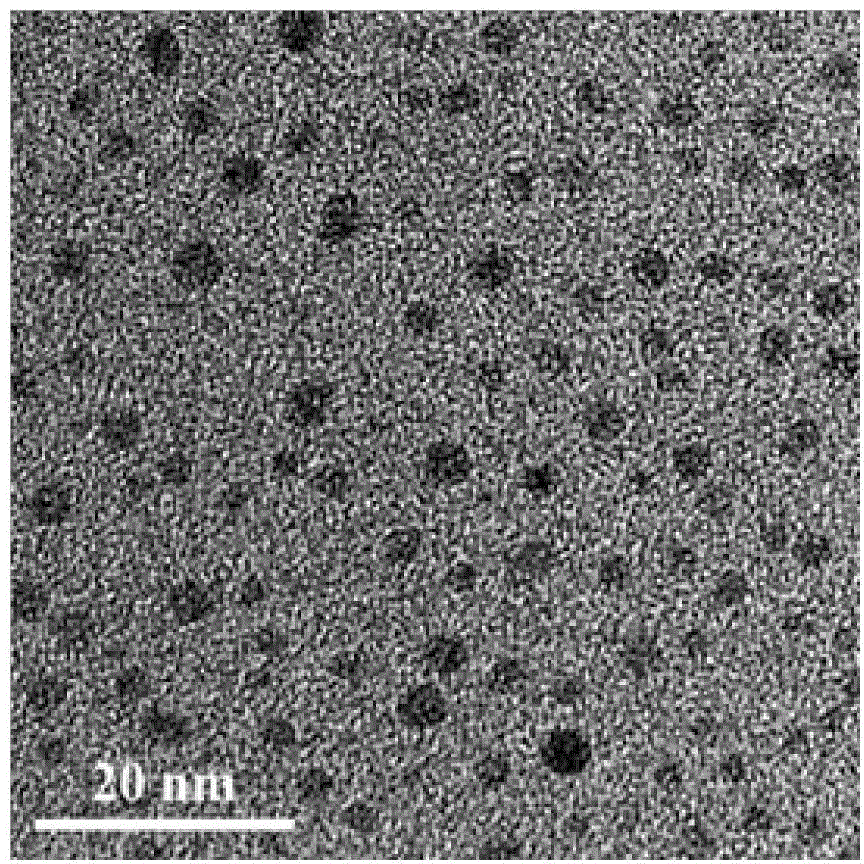

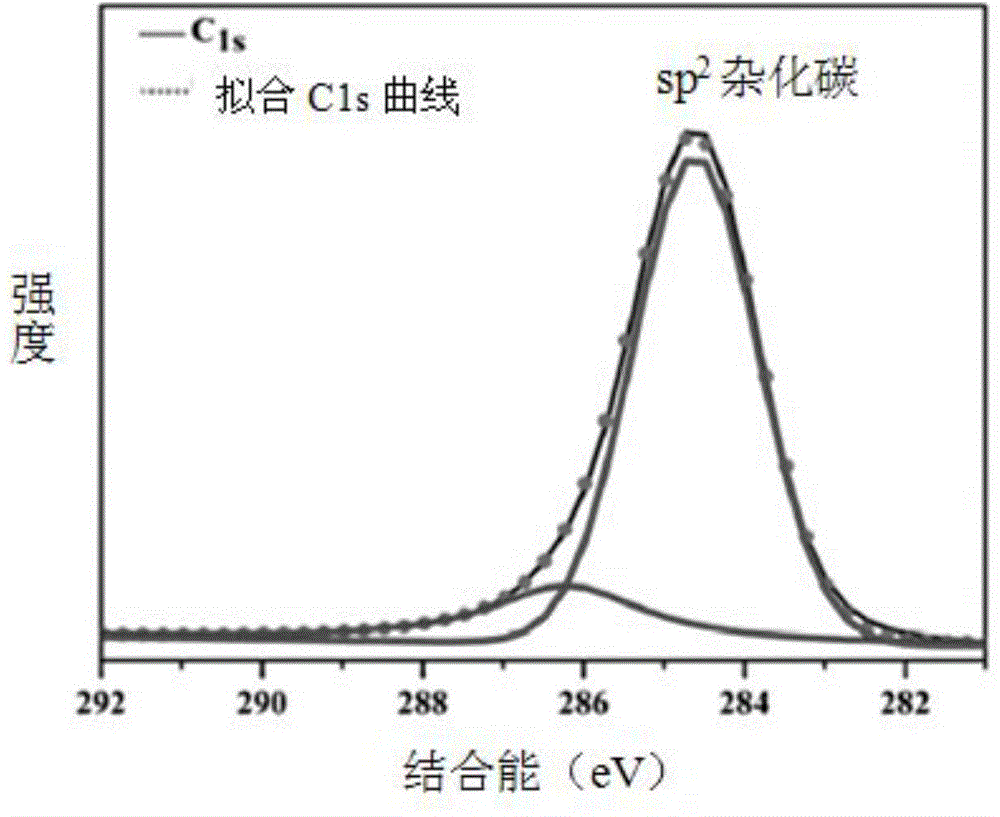

Embodiment 1

[0024] Add 15 μL of concentrated sulfuric acid as an ion catalyst to 15 mL of an aqueous solution of glycerol with a volume fraction of 70%, ultrasonically disperse the mixed solution for 3 minutes, put it into a polytetrafluoroethylene hydrothermal reaction kettle, cover and seal Afterwards, the reaction kettle was put into a muffle furnace, and the temperature was raised to 180° C. for 16 hours. After the reaction was completed, the reaction kettle was cooled to room temperature, and the yellow-brown solution generated in the reaction kettle was poured out, the solid impurities were removed by filtration, and the remaining solution was purified by dialysis. Mix the solution obtained after purification with 5 times the volume of anhydrous DMF solvent and disperse evenly by ultrasonic. After completion, put it into a chemical microwave reactor, set the heating power to 600W, and perform microwave reduction treatment under N2 protection conditions for 2 minutes. After the end, ...

Embodiment 2

[0026] Add 30 μL of concentrated sulfuric acid as an ion catalyst to 30 mL of an aqueous solution of glycerol with a volume fraction of 70%, sonicate the mixed solution for 4 minutes to disperse it evenly, then place it in a polytetrafluoroethylene hydrothermal reaction kettle, cover and seal Afterwards, the reaction kettle was put into a muffle furnace, and the temperature was raised to 200° C. for 20 h. After the reaction was completed, the reaction kettle was cooled to room temperature, and the yellow-brown solution generated in the reaction kettle was poured out, the solid impurities were removed by filtration, and the remaining solution was purified by dialysis. Mix the solution obtained after purification with 5 times the volume of anhydrous DMF solvent and disperse evenly by ultrasonic. After completion, put it into a chemical microwave reactor, set the heating power to 720W, and perform microwave reduction treatment under N2 protection conditions for 3 minutes. After t...

Embodiment 3

[0028] Add 40 μL of concentrated sulfuric acid as an ion catalyst to 40 mL of an aqueous solution of glycerol with a volume fraction of 70%, ultrasonically disperse the mixed solution for 5 minutes, put it into a polytetrafluoroethylene hydrothermal reaction kettle, cover and seal Afterwards, the reaction kettle was put into a muffle furnace, and the temperature was raised to 220° C. for 24 hours. After the reaction was completed, the reaction kettle was cooled to room temperature, and the yellow-brown solution generated in the reaction kettle was poured out, the solid impurities were removed by filtration, and the remaining solution was purified by dialysis. Mix the solution obtained after purification with 5 times the volume of anhydrous DMF solvent and disperse evenly by ultrasonic. After completion, put it into a chemical microwave reactor, set the heating power to 800W, and set 2 Microwave reduction treatment under protected conditions for 5 minutes. After the end, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com