Method for large-scale preparation of oxidized graphene and selective adsorption of thorium in water

A large-scale preparation and graphene technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, inorganic chemistry, etc., can solve the problems of purifying products, limiting large-scale industrial production of graphite oxide, etc., achieving low raw material cost and low cost The effect of low and high adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: concrete steps are as follows:

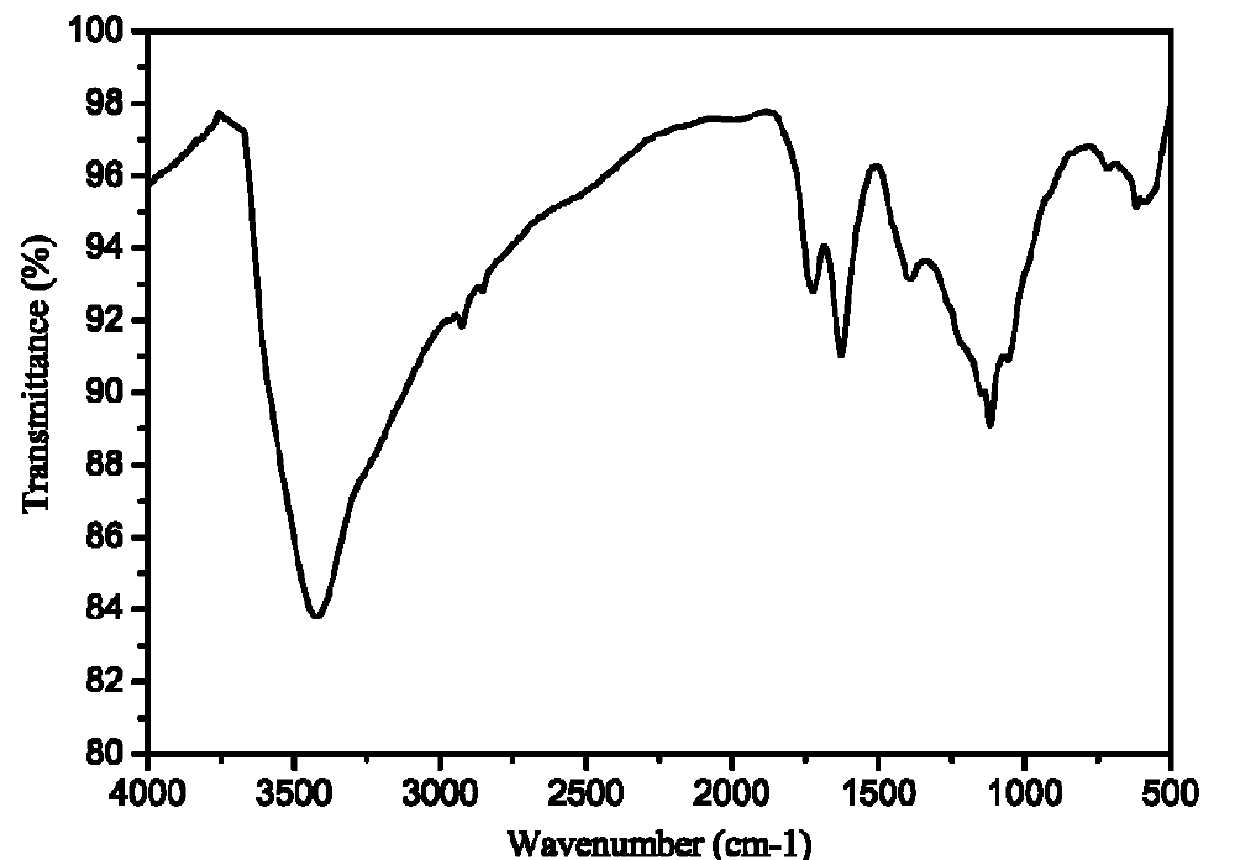

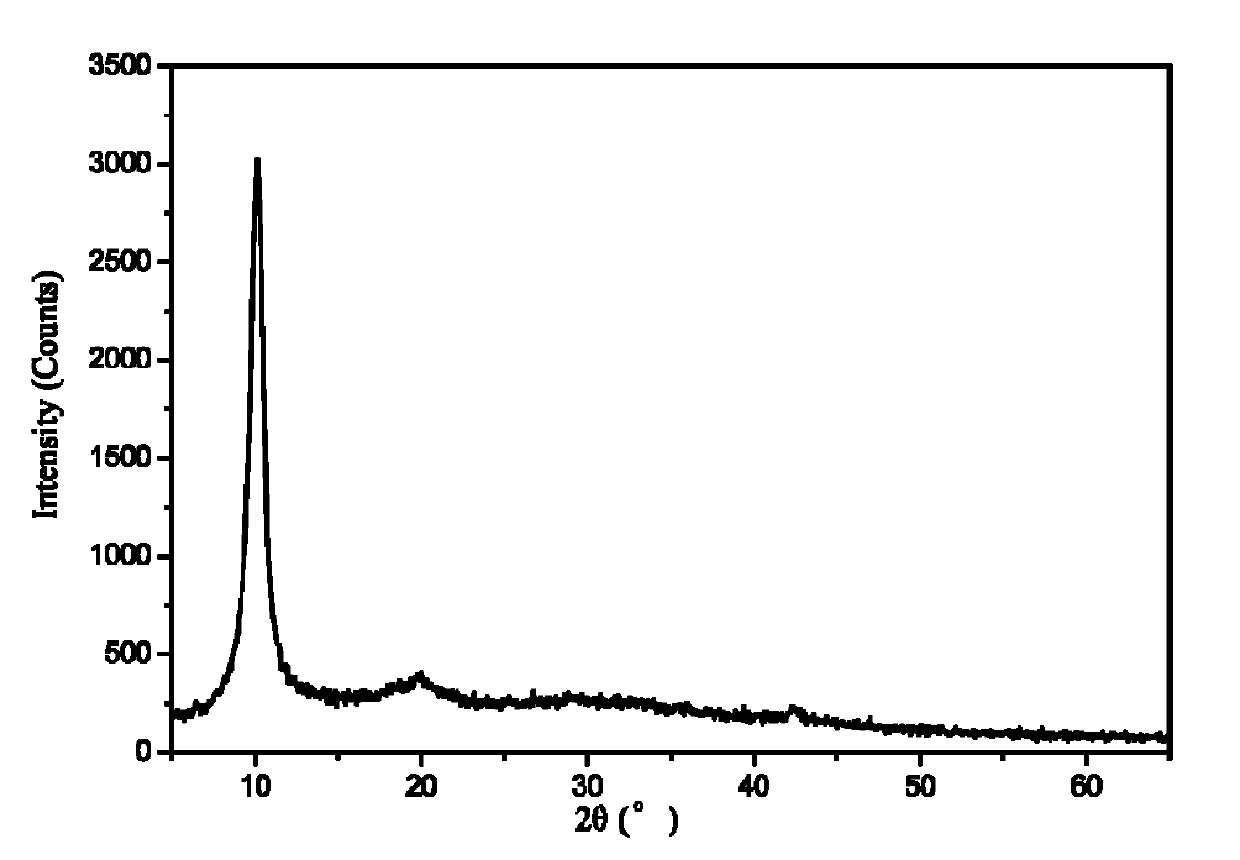

[0034] (1) Preparation of single-layer graphene oxide aqueous dispersion: using graphite powder as raw material, take 10 grams of graphite powder, add 240 ml of concentrated sulfuric acid, stir at 0°C for 30 minutes to mix evenly, and then slowly add 60 gram of potassium permanganate, after adding, continue to stir at 0°C for 2 hours, then transfer to 35°C in a warm water bath and stir for 30 minutes, dilute with 200 ml of deionized water, and continue to dilute at 95°C after dilution Stir under the conditions for 30 minutes, cool to 50°C and add 120 ml of hydrogen peroxide solution; then put the above solution to stand for stratification, pour off the supernatant, add 1 liter of deionized water and 0.3 ml of concentrated hydrochloric acid to wash, repeat the above operation 5 times to remove metal ions; filter under reduced pressure, wash 4 times with deionized water until the pH value of the filtrate remains constant, to re...

Embodiment 2

[0036] Embodiment 2: concrete steps are as follows:

[0037] (1) Preparation of single-layer graphene oxide aqueous dispersion: using graphite powder as raw material, take 50 grams of graphite powder, add 1200 ml of concentrated sulfuric acid, stir at 0°C for 1 hour to mix evenly, and then slowly add 300 gram of potassium permanganate, after adding, continue to stir at 0°C for 5 hours, then transfer to 35°C in a warm water bath and stir for 3 hours, dilute with 1 liter of deionized water, and continue to stir at 95°C after dilution Stir under the same conditions for 1 hour, add 600 ml of hydrogen peroxide solution after cooling to 60 °C; then put the above solution to stand for stratification, pour off the supernatant, add 2 liters of deionized water and 1 ml of concentrated hydrochloric acid to wash, repeat the above operation 10 times to remove metal ions; filter under reduced pressure, wash 8 times with deionized water until the pH value of the filtrate remains constant, to...

Embodiment 3

[0039] Embodiment 3: concrete steps are as follows:

[0040] (1) Preparation of single-layer graphene oxide aqueous dispersion: using graphite powder as raw material, take 100 grams of graphite powder, add 1.2 liters of concentrated sulfuric acid, stir at 0°C for 6 hours to make it evenly mixed, and then slowly add 600 gram of potassium permanganate, after adding, continue to stir at 0°C for 10 hours, then transfer to 35°C in a warm water bath and stir for 5 hours, dilute with 2 liters of deionized water, and continue to dilute at 95°C after dilution Stir under the same conditions for 5 hours, add 1.2 liters of hydrogen peroxide solution after cooling to 40°C; then put the above solution into layers, pour off the supernatant, add 5 liters of deionized water and 4 ml of concentrated hydrochloric acid to wash, repeat the above operation 20 times to remove metal ions; filter under reduced pressure, wash 8 times with deionized water until the pH value of the filtrate remains const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com