Electrocatalyst for fuel cell membrane electrode and preparation method thereof and fuel cell membrane electrode

A fuel cell membrane and electrocatalyst technology, which is applied to fuel cell components, battery electrodes, circuits, etc., can solve the problem of not being able to obtain the effect of non-humidification/self-humidification, and achieve large-scale preparation and non-humidification. The effect of good performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Preparation of composite carrier: Take 0.0155g of tetraethyl orthosilicate and add it to 3ml of ethanol, then add 1 gram of XC-72R carbon black that has been oxidized and heat-treated, and stir at room temperature for 15 minutes to make orthosilicate and carbon black uniform Disperse, then in a vacuum drying oven at 40°C, vacuumize to remove residual ethanol, then heat treat at 300°C for 3h under an inert atmosphere, and cool; that is, a carbon composite carrier material containing silicon dioxide is obtained; it can be expressed as SiO2 / XC-72R or SiO2 / C;

[0041] (2) Preparation of electrocatalyst: take the composite carrier prepared in step (1) as the carrier, and adopt the organic sol method described in patent ZL200510102382. A mixture of acetone and ethylene glycol is used as a solvent, ethylene glycol is used as a reducing agent, chloroplatinic acid is used as a precursor of platinum, and sodium citrate is used as a complexing agent. React in an autoclave at ...

Embodiment 2

[0047] Except that the amount of tetraethyl orthosilicate added is 0.155g, and the SiO2 content is 3% in the catalyst prepared at last, other steps are completely identical with embodiment 1.

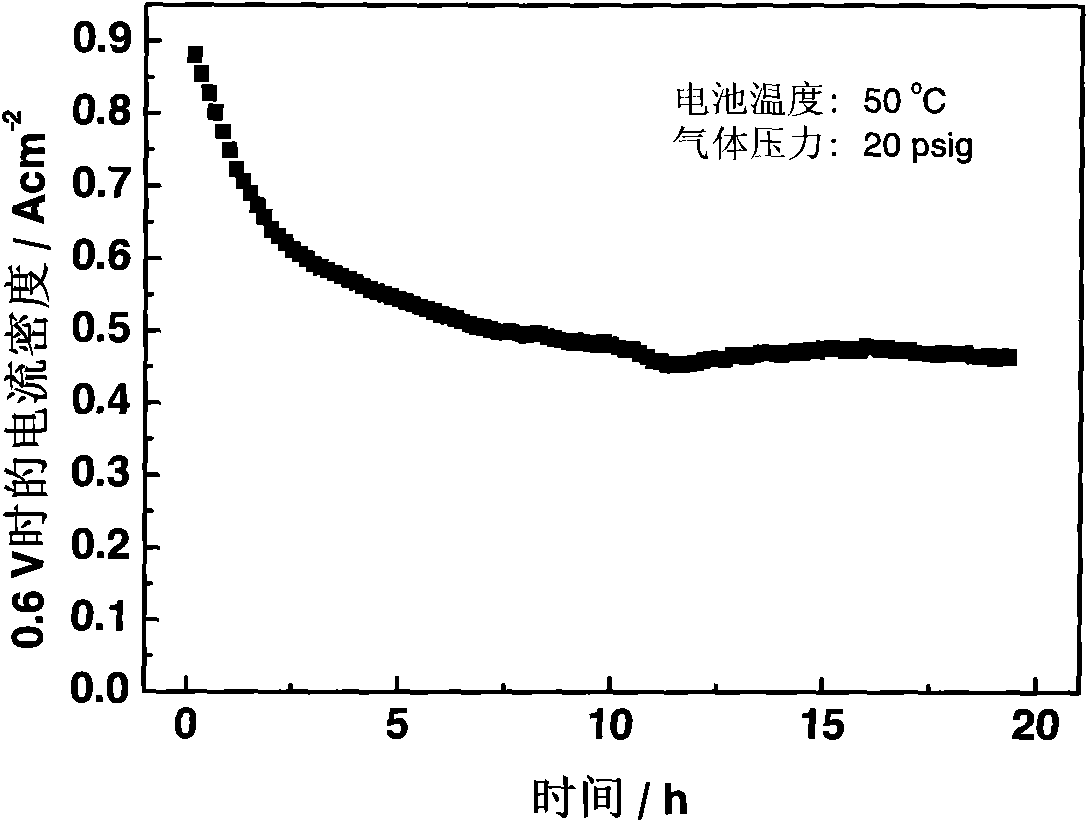

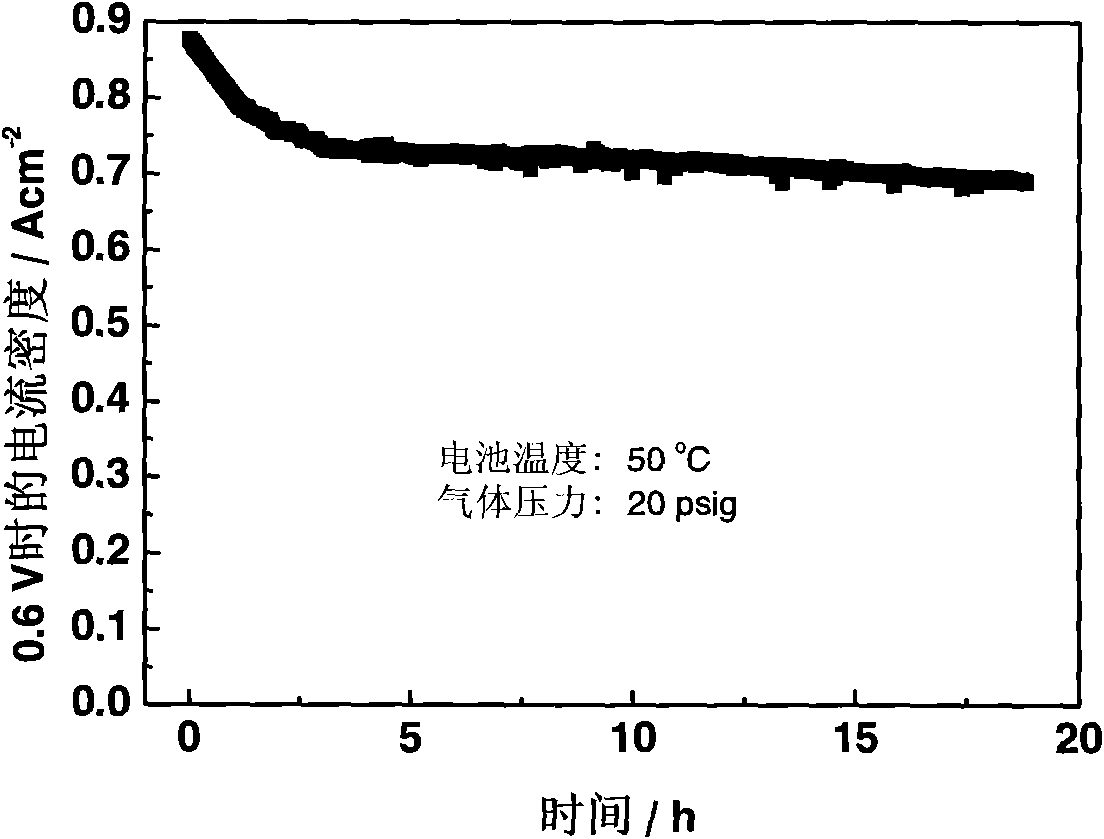

[0048] The results show that: using SiO 2 3% Pt / SiO 2 The membrane electrode made by / C catalyst showed a very good effect of avoiding humidification. Within 3 hours, the current density was only reduced by 200A / cm 2 (from 900mA / cm 2 down to 700mA / cm 2 ), and then basically stable within 20 hours (see figure 2 ).

Embodiment 3

[0053] In addition to increasing the amount of ethyl orthosilicate, and using acetone to replace absolute ethanol as the dispersion medium of ethyl orthosilicate, the catalyst Pt / SiO 2 SiO in / C 2 Content is except 6%, other is with embodiment 1.

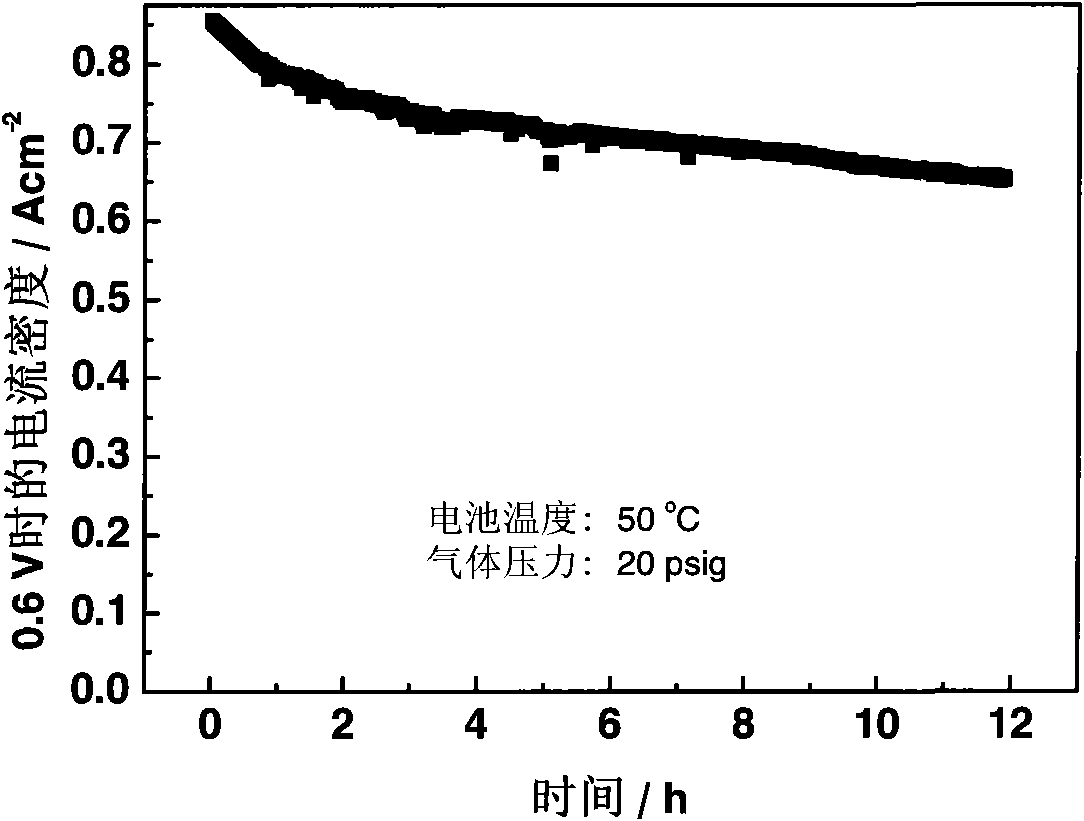

[0054] see results image 3 and Table 1. Its anti-humidification effect is lower than that of the membrane electrode prepared by the catalyst containing 3% silicon dioxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com