Optimized preparation method of oxidized graphite paper

A technology of graphite paper and graphite, applied in the field of nanomaterials, can solve the problems that graphite oxide paper is not suitable for industrial production, and its preparation has not been reported.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

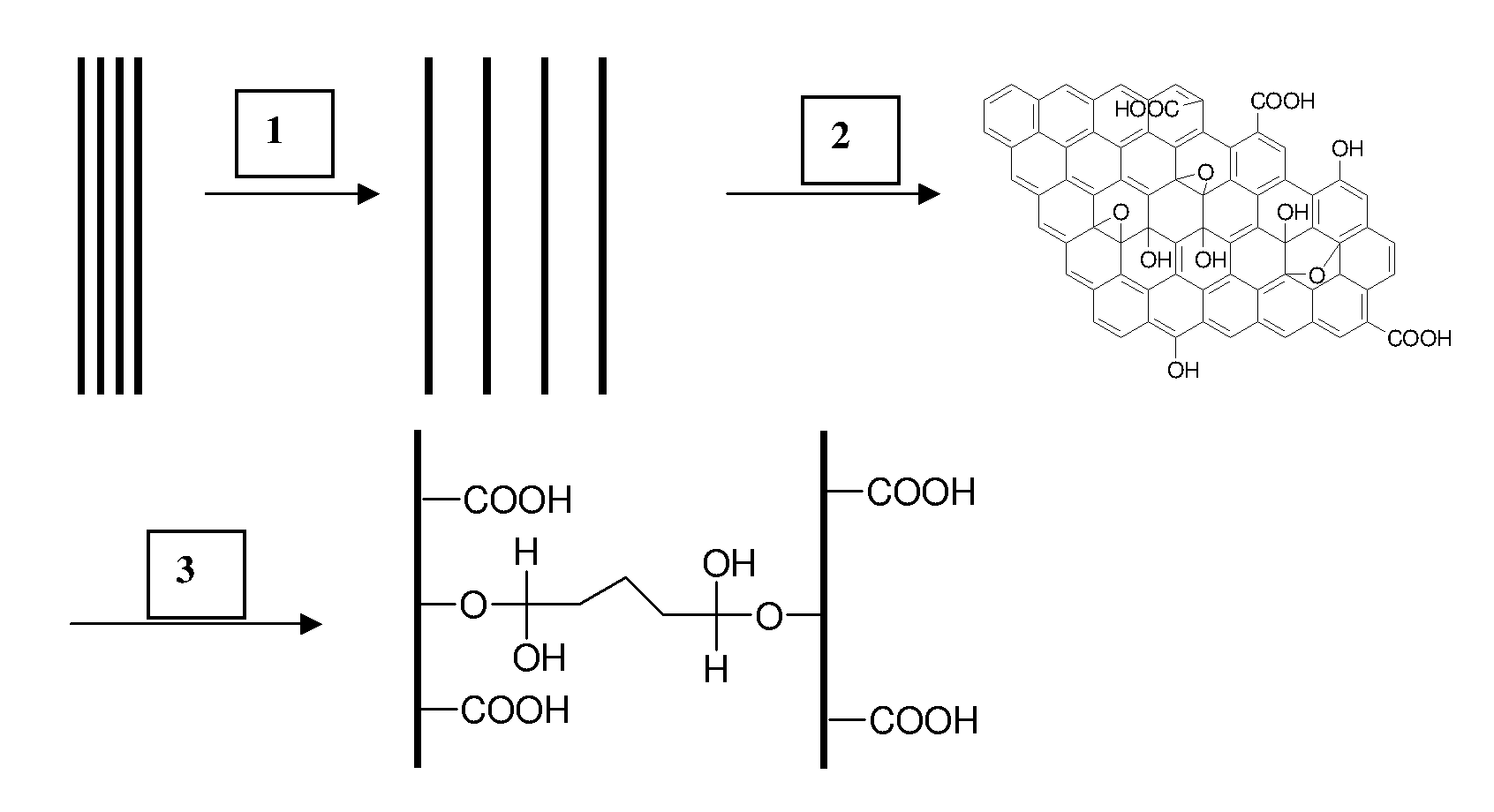

[0029] Such as figure 1 Shown, the large-scale preparation method of the graphite oxide paper described in the present embodiment comprises the following steps:

[0030] The first step, at room temperature, add 10g of 500 mesh natural flake graphite into a 1000mL flask, stir mechanically, add 5g of sodium nitrate, continue stirring for 1h, cool to 0°C in an ice bath, and then, within 5h, batch Add 30g of potassium permanganate, keep the temperature of the reaction system not higher than 15°C, remove the ice bath, heat in a water bath to raise the temperature of the reaction system to 35±3°C, fully stir the reaction for 2 hours, and obtain a brown graphite suspension.

[0031] In the second step, 500 mL of ice water was added into the flask to quench the reaction, and then 35 mL of hydrogen peroxide aqueous solution with a mass percent concentration of 30% was slowly added to obtain a bright yellow graphene oxide suspension.

[0032] The third step is to filter the graphite ox...

Embodiment 2

[0035] Such as figure 1 Shown, the mechanical reinforcement method of the graphite oxide paper described in this embodiment comprises the following steps:

[0036] The first step, at room temperature, add 10g of 500 mesh natural flake graphite into a 1000mL flask, stir mechanically, add 5g of sodium nitrate, continue stirring for 1h, cool to 0°C in an ice bath, and then, within 5h, batch Add 30g of potassium permanganate, keep the temperature of the reaction system not higher than 15°C, remove the ice bath, heat in a water bath to raise the temperature of the reaction system to 35±3°C, fully stir the reaction for 2 hours, and obtain a brown graphite suspension.

[0037] In the second step, 500 mL of ice water was added into the flask to quench the reaction, and then 35 mL of hydrogen peroxide aqueous solution with a mass percent concentration of 30% was slowly added to obtain a bright yellow graphene oxide suspension.

[0038] The third step is to filter the graphite oxide su...

Embodiment 3

[0041] The steps are as in Example 1. During the process of adding potassium permanganate, the cooling temperature is lowered to -10° C., and the average size of the obtained flake graphene increases by 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com