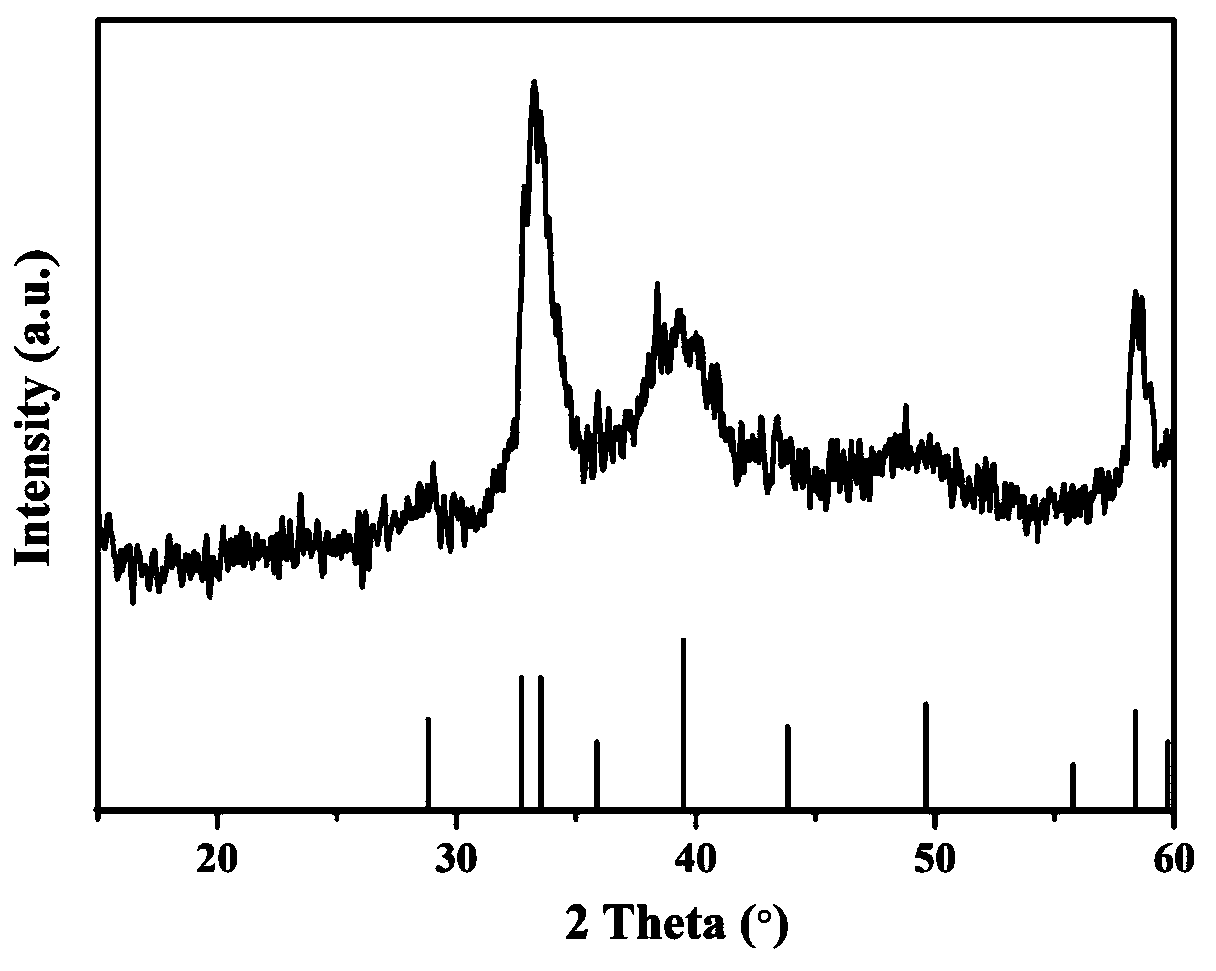

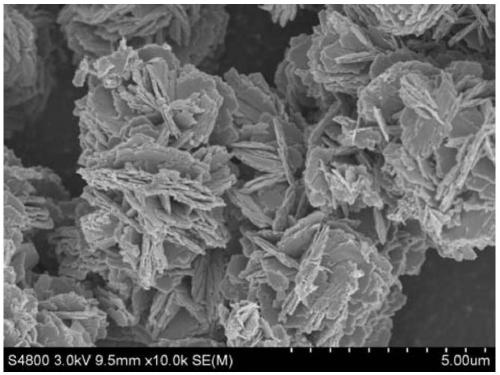

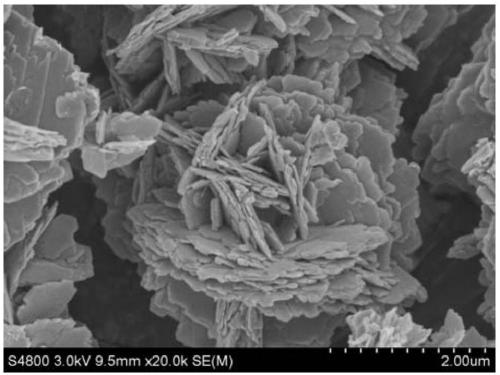

Preparation method of three-dimensional self-assembled flower-like tungsten disulfide electrode material

A technology of tungsten disulfide and electrode materials, applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve problems such as structural damage, electrochemical performance attenuation, large volume expansion, etc., achieve good crystallinity, facilitate transmission, The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: At room temperature, add 0.659g of sodium tungstate dihydrate into a mixed solution formed by 25mL of deionized water and 10mL of ethanol, and stir until completely dissolved to form a transparent solution A;

[0029] Step 2: Add 0.1g of ammonium acetate into the transparent solution A and stir until dissolved, then add 2mL of oleic acid into the transparent solution A, stir magnetically until the oleic acid is completely dissolved, the stirring speed is 500r / min, and the stirring time is 0.5h;

[0030] Step 3: Dilute concentrated hydrochloric acid into 2mol / L transparent solution B, add solution B dropwise to the above solution until the pH value of the solution is 1.5, transfer the solution to a polytetrafluoroethylene reactor for homogeneous reaction, the reaction temperature 180°C, reaction time 12h, after the reaction, freeze-dry after centrifugation to obtain WO 3 0.33H 2 O;

[0031] Step 4: Convert the obtained WO 3 0.33H 2 O powder was used as tungst...

Embodiment 2

[0033] Step 1: At room temperature, add 0.711g of sodium tungstate dihydrate into a mixed solution formed by 25mL of deionized water and 10mL of ethanol, and stir until completely dissolved to form a transparent solution A;

[0034] Step 2: Add 0.3g of ammonium acetate into the transparent solution A and stir until dissolved, then add 2mL of oleic acid into the transparent solution A, stir magnetically until the oleic acid is completely dissolved, the stirring speed is 400r / min, and the stirring time is 0.5h;

[0035] Step 3: Dilute concentrated hydrochloric acid into 1mol / L transparent solution B, add solution B dropwise to the above solution until the pH value of the solution is 1.4, transfer the solution to a polytetrafluoroethylene reactor for homogeneous reaction, and the reaction temperature 160°C, reaction time 12h, after the reaction, freeze-dry after centrifugation to obtain WO 3 0.33H 2 O;

[0036] Step 4: Convert the obtained WO 3 0.33H 2 O powder was used as tu...

Embodiment 3

[0038] Step 1: At room temperature, add 0.825g of sodium tungstate dihydrate into a mixed solution formed by 25mL of deionized water and 10mL of ethanol, and stir until completely dissolved to form a transparent solution A;

[0039] Step 2: Add 0.15g of ammonium acetate into the transparent solution A and stir until dissolved, then add 2mL of oleic acid into the transparent solution A, stir magnetically until the oleic acid is completely dissolved, the stirring speed is 500r / min, and the stirring time is 1h;

[0040] Step 3: Dilute concentrated hydrochloric acid into 2mol / L transparent solution B, add solution B dropwise to the above solution until the pH value of the solution is 1.5, transfer the solution to a polytetrafluoroethylene reactor for homogeneous reaction, the reaction temperature 180°C, reaction time 12h, after the reaction, freeze-dry after centrifugation to obtain WO 3 0.33H 2 O;

[0041]Step 4: Convert the obtained WO 3 0.33H 2 O powder was used as tungsten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com