Titanium dioxide nanometer composite material, and preparation methods and use thereof

A nanocomposite material and titanium dioxide technology, applied in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc., can solve problems such as loss, secondary pollution, reunion, etc., and achieve low cost and good adsorption effect , the effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1) Disperse commercially available cellulose fiber (CF) (1g) in water (150ml), then slowly add concentrated sulfuric acid (2ml) dropwise while stirring;

[0056] 2) Add titanyl sulfate (TiOSO) dropwise in the above fiber dispersion 4 ) (0.8ml), while continuing to stir;

[0057] 3) Heating in a water bath at 70°C for 4 hours while stirring;

[0058] 4) After the reaction is completed, cool down, then vacuum filter, rinse the fibrous filter cake with deionized water several times, and dry at 40°C to obtain TiO 2 / Cellulose fiber nanocomposites.

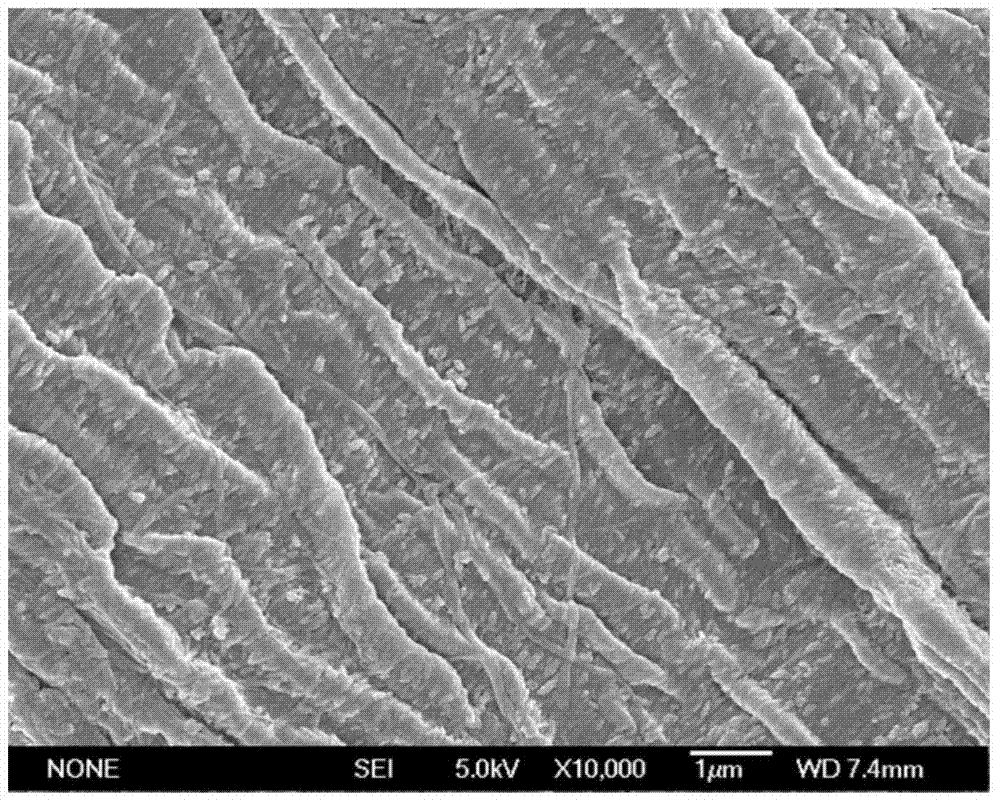

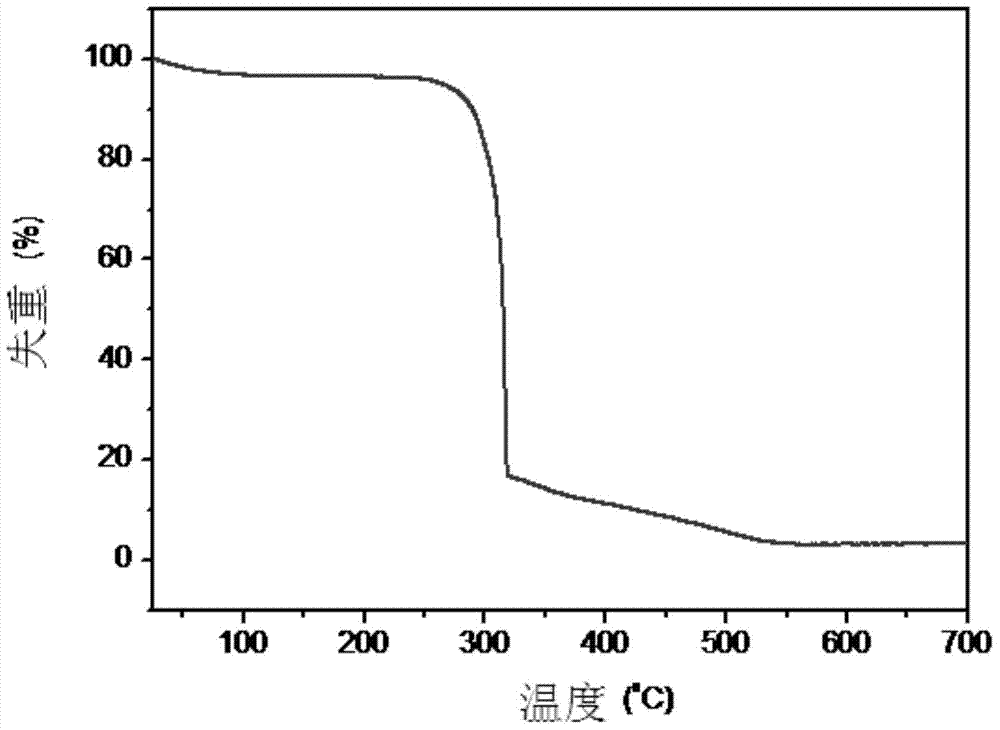

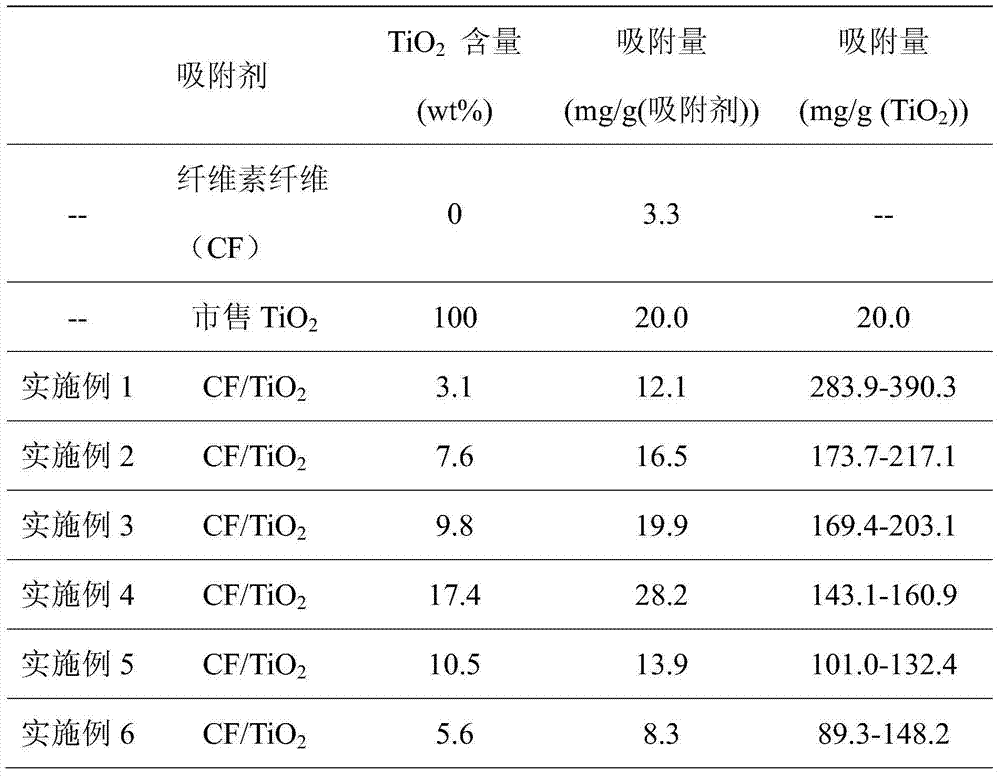

[0059] figure 1 The surface morphology of the composite material obtained for this example, TiO 2 Nanoparticles are uniformly dispersed on the surface of cellulose; figure 2 For the thermogravimetric analysis of composite material that this embodiment makes, the result shows that TiO 2 The content is 3.1wt%.

Embodiment 2

[0061] 1) Disperse commercially available cellulose fiber (1g) in water (200ml), then slowly add concentrated sulfuric acid (4ml) dropwise while stirring;

[0062] 2) Add TiOSO dropwise to the above fiber dispersion 4 (2.4ml), while continuing to stir;

[0063] 3) Heating in a water bath at 90°C for 3 hours while stirring;

[0064] 4) After the reaction is completed, cool down, then vacuum filter, rinse the fibrous filter cake with deionized water several times, and dry at 40°C to obtain TiO 2 / Cellulose fiber nanocomposites.

Embodiment 3

[0066] 1) Dissolve n-butyl titanate (15ml) in 15ml of isopropanol, then slowly add it dropwise into 150ml of water while stirring;

[0067] 2) Add 1ml of nitric acid to the above solution, and continue stirring at room temperature for 2 hours to obtain TiO 2 Sol;

[0068] 3) The cellulose fibers were placed in the above TiO 2 Sol impregnation-suction filtration, so that the surface of cellulose fibers is pre-coated with TiO 2 film;

[0069] 4) Take n-butyl titanate (1ml) and add it to 50ml of hydrochloric acid solution (25ml HCl+25ml water), stir for 10min, then pour it into a reaction kettle lined with polytetrafluoroethylene;

[0070] 5) Will be pre-coated with TiO 2 The cellulose fibers were immersed in the above precursor solution, and the reaction kettle was sealed and heated in a 70°C thermostat for 4 hours;

[0071] 6) After the reaction is completed, after the temperature of the incubator is cooled to room temperature, the reaction kettle is taken out, the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com