Preparation method of magnetic nano ferric oxide

A magnetic nanometer and iron oxide technology, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, etc., can solve the problems of poor magnetic properties of the crystal structure and limited biomedical applications, and achieve dense iron core crystals and good crystallinity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

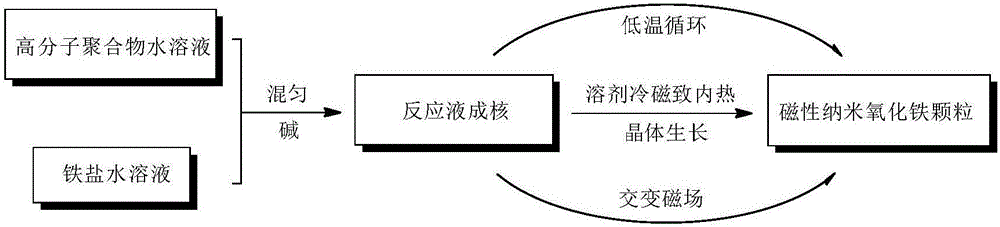

Method used

Image

Examples

Embodiment 1

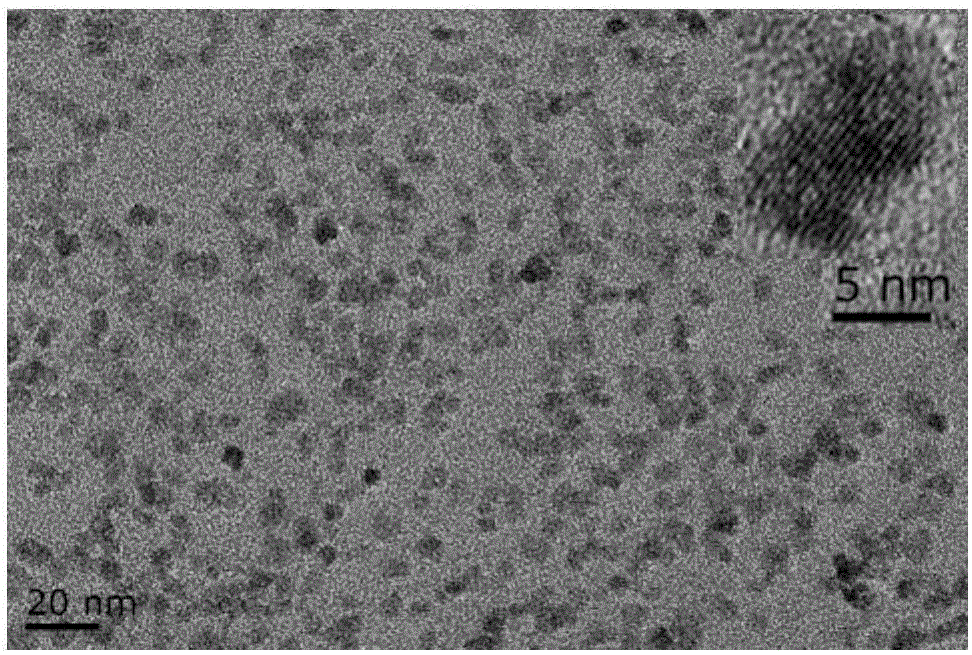

[0021] 168mg of polydextrose sorbitol carboxymethyl ether was placed in a 5mL plastic cryovial, and 2.5mL of ultrapure water was added, sonicated to fully dissolve it. Add 92 mg of ferric chloride hexahydrate and 46 mg of ferrous chloride tetrahydrate into 1.5 mL of ultrapure water, and after fully dissolving, add the solution into the solution of polydextrose sorbitol carboxymethyl ether. Shake and mix well at room temperature, under nitrogen protection for 10 minutes. The reaction vessel is placed in high-frequency induction heating equipment (the high-frequency induction heating equipment model is SPG-06-I, or SPG-06-II, or SPG-06-III, or SPG-06-IV, purchased from In the center of the induction coil of Shenzhen Shuangping Power Technology Co., Ltd., industrial alcohol is used for external circulation, and the temperature of the solution is monitored by an optical fiber temperature probe to keep it at 0°C ± 0.4°C for 5 minutes. Turn on the high-frequency induction heating e...

Embodiment 2

[0023] 138mg of polydextrose sorbitol carboxymethyl ether was placed in a 5mL plastic cryovial, and 2mL of ultrapure water was added, sonicated to fully dissolve it. Add 100 mg of ferric chloride hexahydrate and 50 mg of ferrous chloride tetrahydrate into 1 mL of ultrapure water, and after fully dissolving, add the solution into the solution of polydextrose sorbitol carboxymethyl ether. Mix well at room temperature, under nitrogen protection for 10 minutes. The reaction vessel was placed in the center of the induction coil of the high-frequency induction heating equipment, and the external circulation was carried out by industrial alcohol to ensure a low temperature environment. The temperature of the solution was monitored by an optical fiber temperature measuring probe to keep it at 5°C ± 0.4°C for 5 minutes. Turn on the high-frequency induction heating equipment to generate an alternating magnetic field, adjust the output current to 25 amperes, and slowly add 0.5 mL of conc...

Embodiment 3

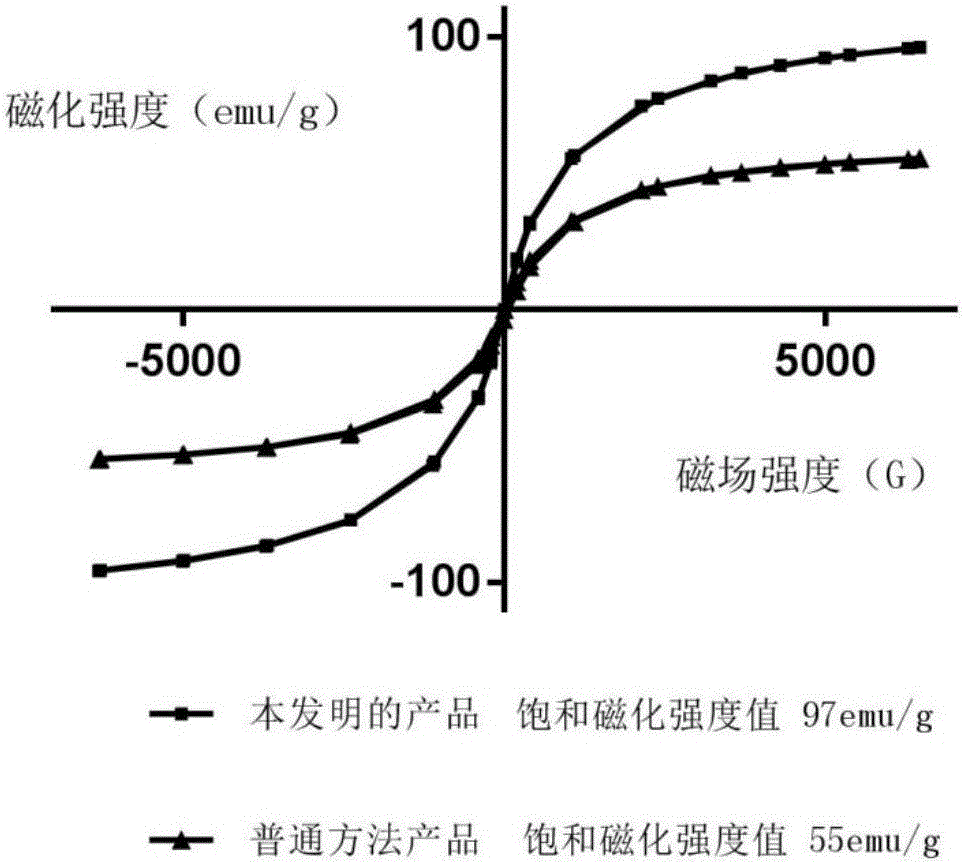

[0026] Example 3 Measurement of Hysteresis Loop and Saturation Magnetization of Products Prepared by Two Methods

[0027] The two samples were adjusted to a solution with a concentration of 10 mg / mL (calculated as iron), respectively added to the sample pool, placed in the built-in magnetic field of the vibrating sample magnetometer (Lakeshore 7407), and the equipment and test software were turned on. The hysteresis loop and saturation magnetization of the sample were obtained by self-detection, and the results are shown in the attached manual. image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com