Solventing-out crystallization device and method through auxiliary control of films

A technology of dissolution crystallization and auxiliary control, which is applied in the general layout of the crystallization device, solution crystallization, selection of auxiliary crystallization conditions, etc. limited and other problems, to achieve the effect of controlling the morphology and particle size distribution, easy to scale up and down, and high quality of crystalline products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

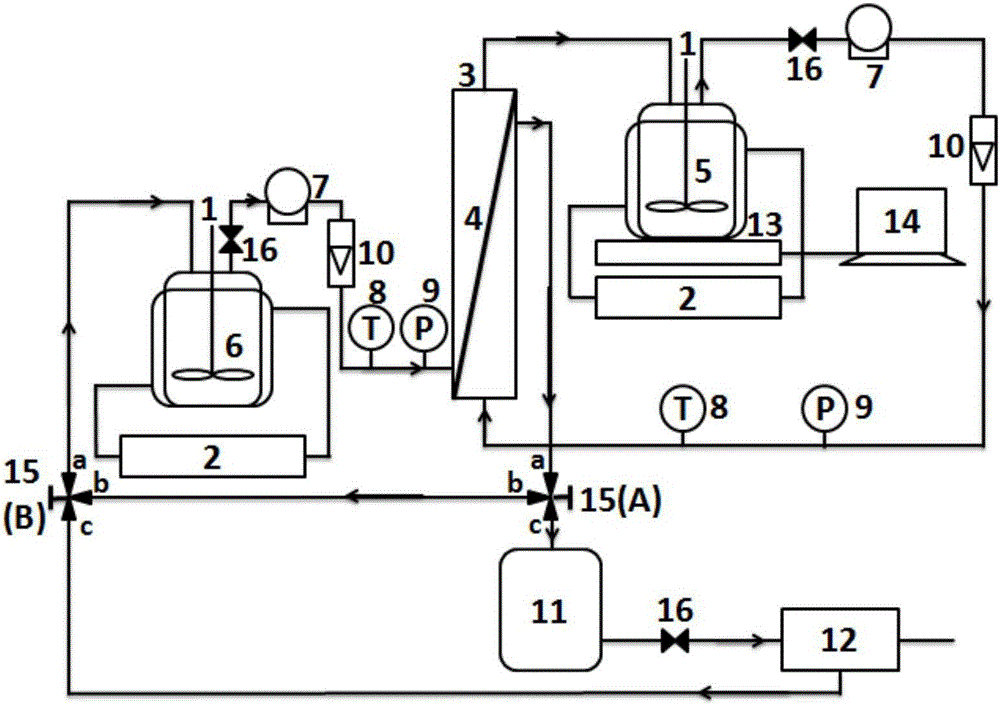

[0033] Take the PES hollow fiber membrane to make a membrane module, and the packing ratio is 0.6. Take 80g of NaCl and add it into deionized water to prepare a saturated solution at 25°C. Add the prepared crystallization solution into the raw material tank, and turn on the stirring device. Adjust the temperature control device to 25°C, turn on the circulating water, and maintain the running state for 30 minutes. Add an appropriate amount of ethanol to the feed liquid tank, turn on the temperature control device, adjust to 25°C, turn on the circulating water, electronic balance and computer, and maintain the running state for 30 minutes. After the temperature is stable, open ports a and b of three-way valves A and B, close port c, open the valve of the ethanol feed liquid tank, and adjust the peristaltic pump to 50rpm to allow ethanol to flow through the membrane module. After the ethanol runs stably, open the valve of the raw material tank and adjust the peristaltic pump so...

Embodiment 2

[0035] Take the PES flat membrane to make a membrane module. Take 80g of NaCl and add it into deionized water to prepare a saturated solution at 25°C. Slowly add ethanol dropwise to the solution and stir fully to make the solution close to supersaturated, but not supersaturated. Add the prepared crystallization solution into the raw material tank, and turn on the stirring device. Adjust the temperature control device to 25°C, turn on the circulating water, and maintain the running state for 30 minutes. Add an appropriate amount of ethanol to the feed liquid tank, turn on the temperature control device, adjust to 25°C, turn on the circulating water, electronic balance and computer, and maintain the running state for 30 minutes. After the temperature is stable, open ports a and c of three-way valves A and B, close port b, open the valve of the ethanol feed liquid tank, and adjust the peristaltic pump to 200rpm to allow ethanol to pass through the membrane module at high speed. ...

Embodiment 3

[0037] Take the PTFE hollow fiber membrane to make the membrane module, and the packing ratio is 0.1. Take 25g of L-asparagine and add it into deionized water to prepare a saturated solution at 25°C. Slowly add isopropanol dropwise to the solution, and stir well, so that the solution is close to supersaturated, but not supersaturated. Add the prepared crystallization solution into the raw material tank, and turn on the stirring device. Adjust the temperature control device to 25°C, turn on the circulating water, and maintain the running state for 30 minutes. Add an appropriate amount of isopropanol to the feed liquid tank, turn on the temperature control device, adjust it to 25°C, turn on the circulating water, electronic balance and computer, and keep it running for 30 minutes. After the temperature is stable, open ports a and c of the three-way valves A and B, close port b, open the valve of the isopropanol feed liquid tank, and adjust the peristalsis to 200rpm to allow iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com