Growth technology for growing high-quality GaN crystal material on sapphire patterned substrate

A technology for patterning substrates and sapphire substrates, applied in the field of physical and chemical growth technology, can solve problems such as weak control ability, difficulty in obtaining high-quality GaN materials, and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

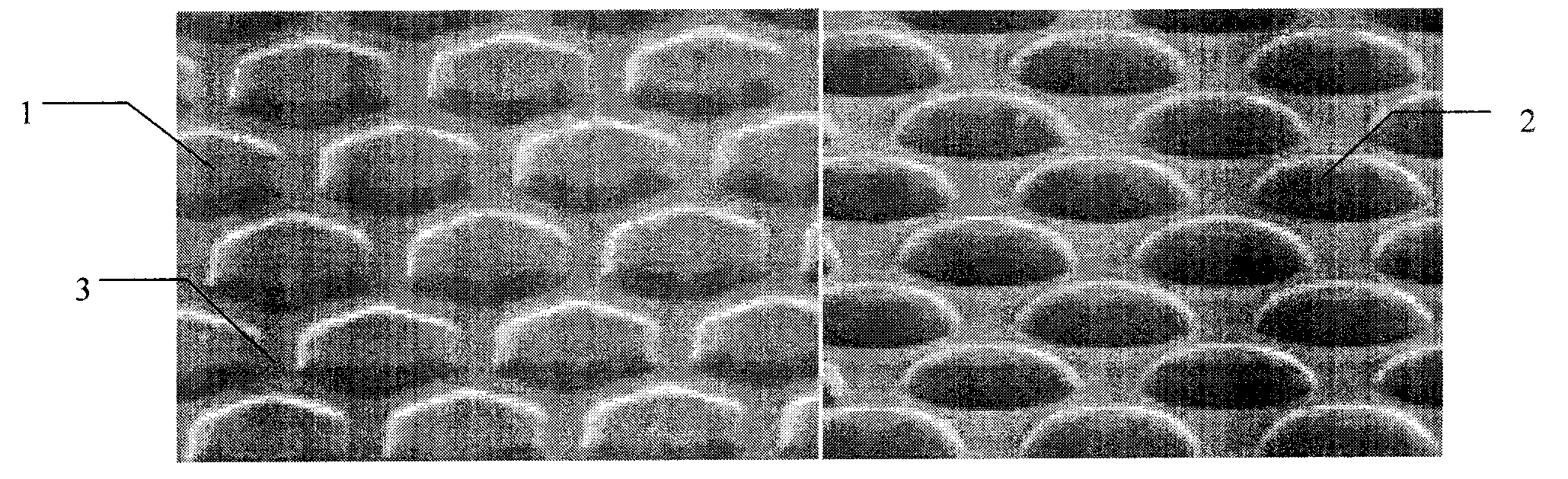

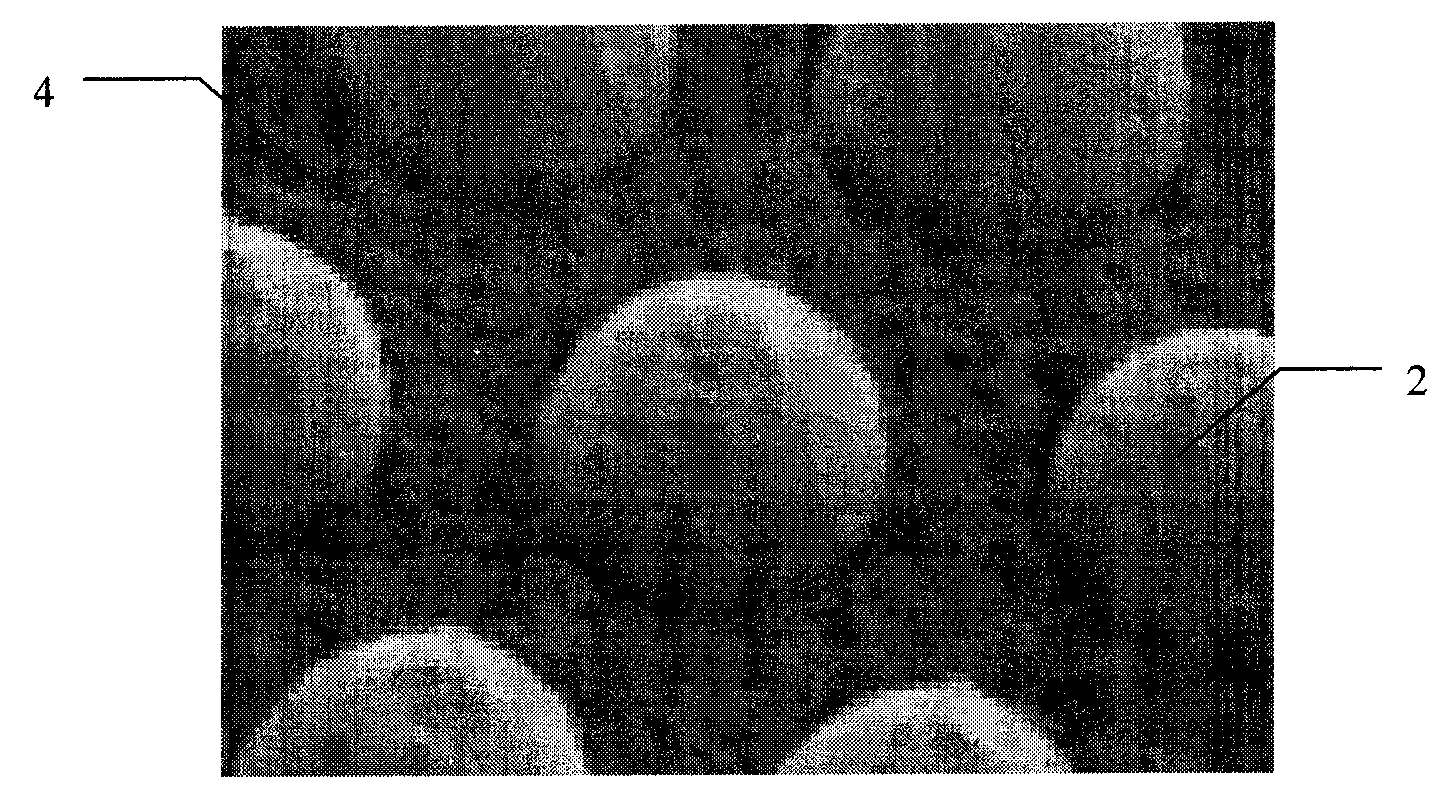

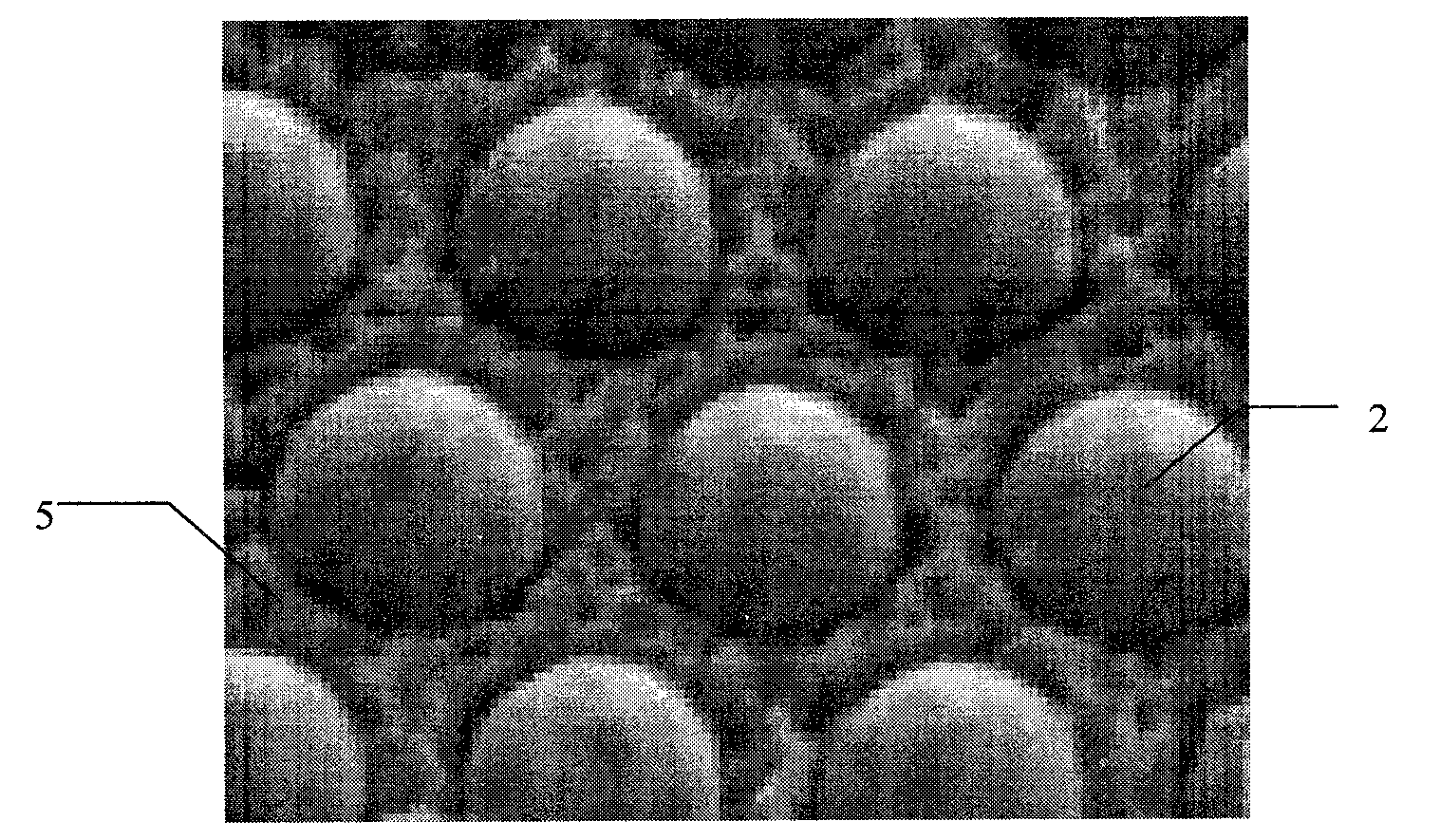

[0021] The realization process of the technical scheme of the present invention is: heating the substrate material temperature to 470-570° C. and feeding Ga element MO source and NH3 as N source to grow GaN crystal nucleation layer material. The typical thickness of the nucleation layer growth is 0.5 microns. After the growth of the nucleation layer is completed, stop feeding the Ga element MO source and quickly raise the temperature of the substrate material to 980-1090 ° C. During this process, the flow of NH3 is still kept constant. The recrystallization growth of GaN crystal is carried out by Ga element MO source. The recrystallization growth process is a process of GaN material growth and decomposition at the same time. Typical values for the growth time are 2 to 3 times the time to grow the first nucleation layer.

[0022] After the first recrystallization process is over, stop feeding the Ga element MO source and quickly cool down the substrate material to 470-570 °C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com