Method for inducing and preparing Co-ZIF-67 metal organic framework membrane by utilizing different-source zinc oxide layer

A metal-organic framework, co-zif-67 technology, applied in the field of preparing Co-ZIF-67 metal-organic framework films induced by different source zinc oxide layers, can solve the problems of weak bonding force between the film and the carrier surface, and achieve good preparation The effect of repeatability, good mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

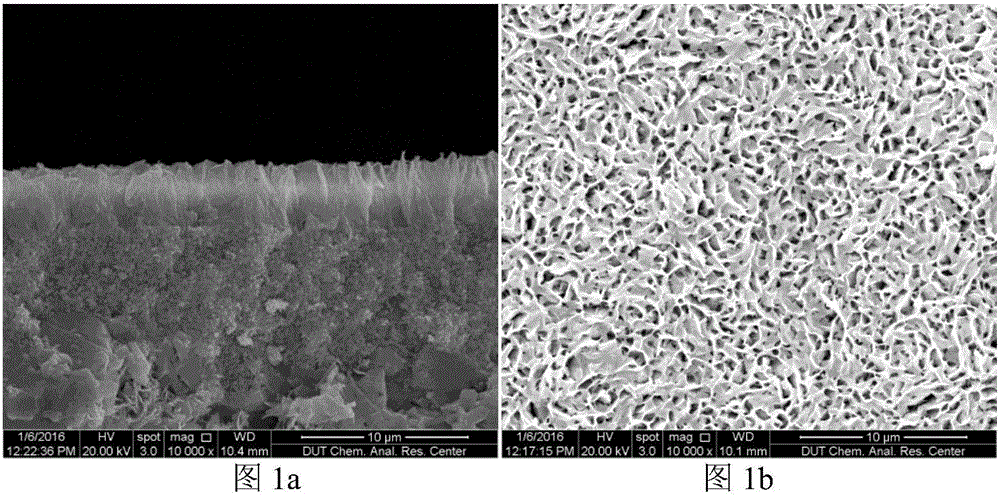

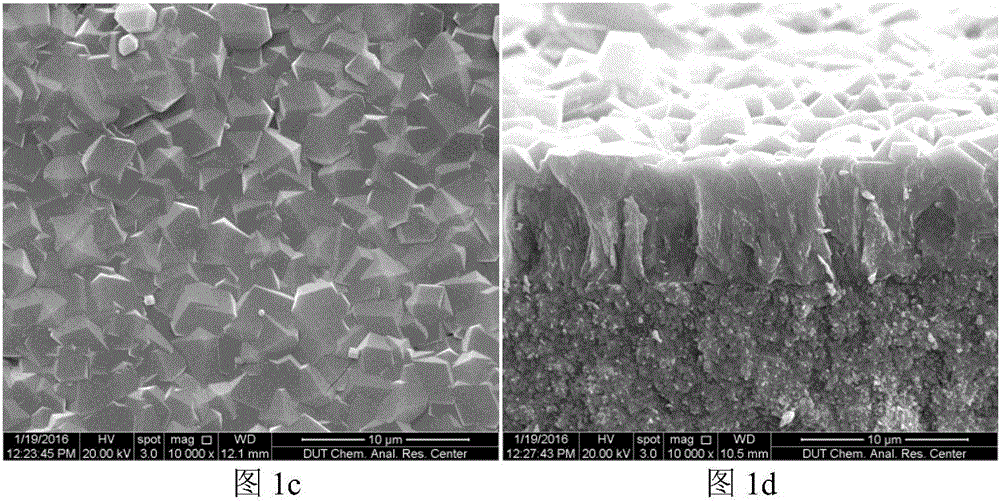

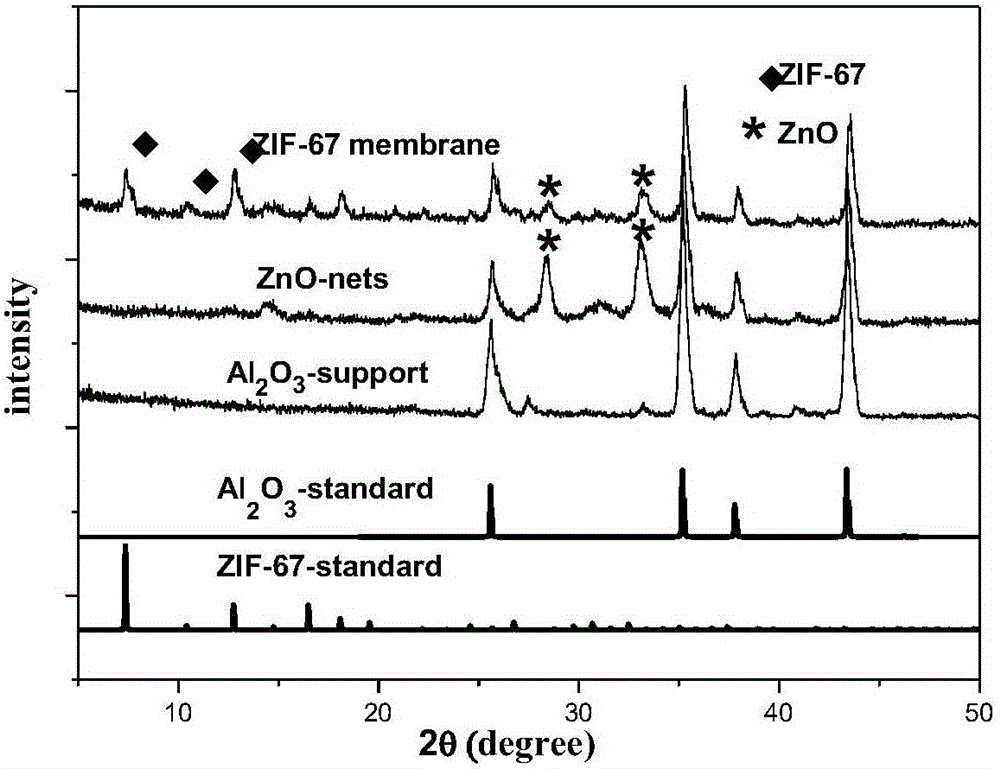

[0042] Example 1: Synthesis of Co-ZIF-67 film induced by zinc oxide nano-network connection layer.

[0043] (1) Carrier pretreatment:

[0044] Before synthesis, use deionized water and ethanol to ultrasonically wash several times to remove surface particles and stains; bake in a muffle furnace at 500°C for 2 hours to remove organic impurities, and place it in a desiccator after cooling down to room temperature for later use.

[0045] (2) The inner surface of the alumina ceramic tube carrier is introduced with a zinc oxide nano-network connection layer:

[0046] The molar ratio is Zn(CH 3 COO) 2 2H 2 O, CO (NH 2 ) 2 , NaCl, EDTA=1:6:0.368:0.15:180:400 is a synthetic solution, the outer wall of the ceramic tube is tightly wrapped with polytetrafluoroethylene, suspended vertically in the kettle, reacted at 90°C for 10 hours, and dried naturally. Rinse with deionized water, and the inner wall of the ceramic tube can get a zinc oxide network connection layer with a thickness ...

Embodiment 2

[0054] The experimental steps of Example 1 were repeated, except that in step (3), the synthesis temperature of Co-ZIF-67 was 80°C. attached by Figure 2a , 2b It can be seen that if the synthesis temperature of the Co-ZIF-67 film is lowered to 80°C, a continuous and dense film layer with a thickness of about 7 μm can still be formed. 俥

Embodiment 3

[0056] Repeat the experimental procedure of Example 1, the difference is that before step (3), the 2-MIm methanol solution of 0.5mol / L is used to activate the ZnO mesh layer at 50°C for 0.5h, and the attached Figure 3a , 3b It can be seen that the film is formed after activation by ligand methanol solution, and the film layer is more uniform, continuous and defect-free.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com