Steel fiber reinforced concrete vibration leveling construction method for bridge deck reinforcement

A technology of steel fiber concrete and construction method, which is applied in the direction of road construction reinforcements, bridges, bridge parts, etc., which can solve the problems of low preparation efficiency, difficult operation of steel fiber directional arrangement, and affecting the construction efficiency of bridge deck pavement, etc. To achieve the effect of rapid orientation arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

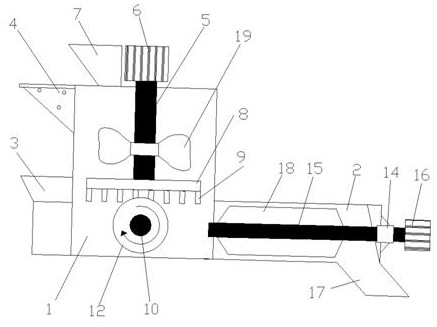

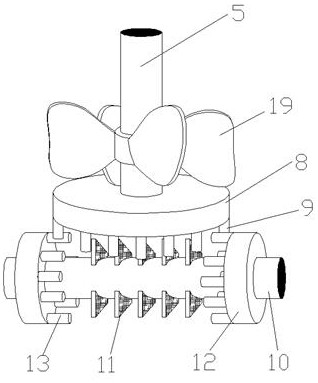

[0036] refer to Figure 1-2 , a steel fiber concrete vibration leveling construction method for bridge deck reinforcement, comprising the following steps:

[0037] S1. Bridge deck finishing: including bridge deck standard leveling, steel bar leveling, impact decaking and chiseling treatment;

[0038]S2. On-site mixing of steel fiber concrete: concrete and steel fibers are added to the special mixer at the same time according to the weight ratio of 3-5:1, and the on-site mixing is carried out. The special mixer is suspended by driving the headstock. And discharge the material onto the bridge surface at a uniform speed on site;

[0039] The special mixing machine inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com