Broad-spectrum aged oil demulsifier and preparation method thereof

A technology of oil demulsifier and crude oil demulsifier, which can be used in chemical dehydration/demulsification, petroleum industry, treatment of hydrocarbon oil, etc. Wetness and permeability, the effect of reducing the oil-water interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

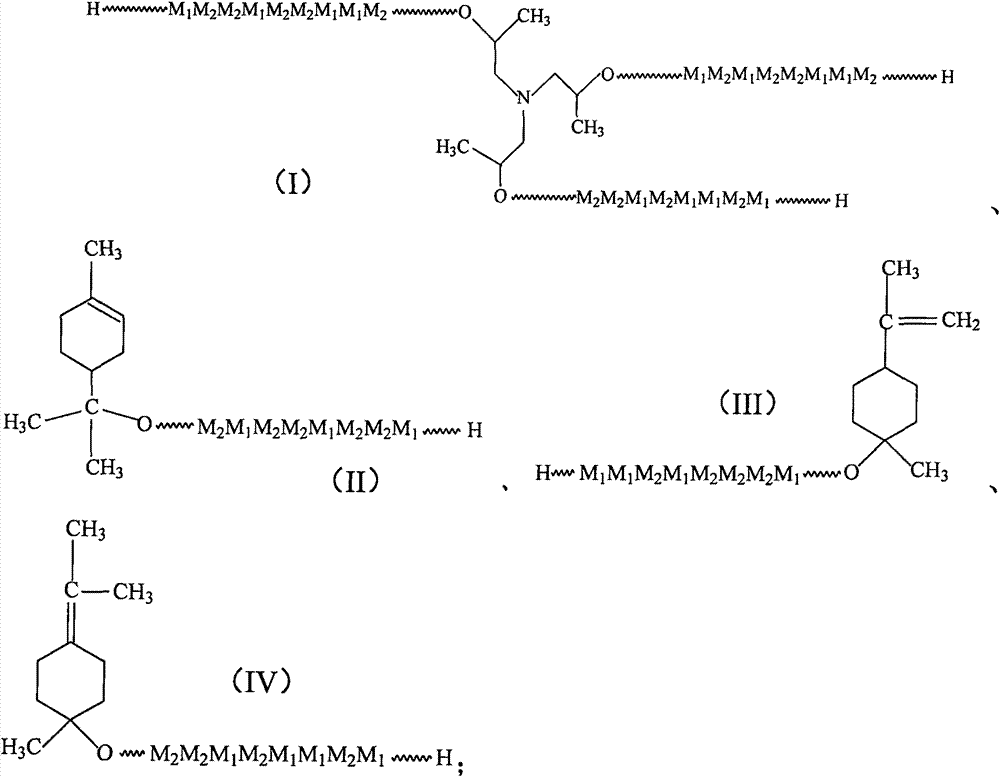

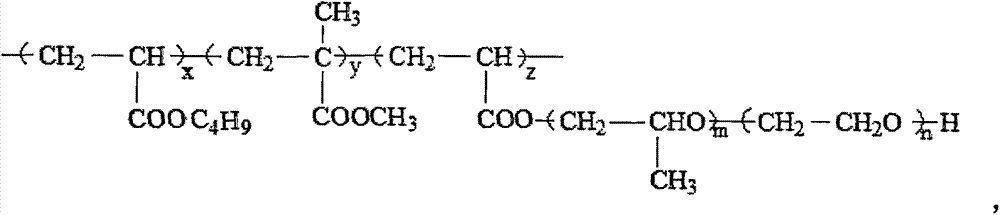

Method used

Image

Examples

Embodiment 1

[0039] 1. A broad-spectrum aging oil demulsifier, consisting of the following components in percentage by weight:

[0040] Ultra-high molecular weight crude oil demulsifier FL-1 (solid content 10%): 10%

[0041] Terpolymer: 23%

[0042] Sodium perfluorononenyloxybenzenesulfonate: 2%

[0043] Lauryl Glucoside: 3%

[0044] Polyethyleneimine (n=50): 10%

[0045] Isotridecanyl polyoxyethylene ether (P=9): 3%

[0046] Acryloylmorpholine: 4%

[0047] Mixed solvent: methanol, dimethylformamide and deionized water (mass ratio 6:3:1) = 45%

[0048] 2. The preparation process of the above-mentioned broad-spectrum aging oil demulsifier:

[0049] 2.1 At room temperature, according to the weight percentage, first put the mixed solvent in the reaction kettle, start stirring, and then stir for about 10-20 minutes after the dropwise addition, until the sample is transparent.

[0050] 2.2 Continuously add ternary copolyether into the reactor to stir, mix and fully dissolve, then add sod...

Embodiment 2

[0061] 1. A broad-spectrum aging oil demulsifier, consisting of the following components in percentage by weight:

[0062] Ultra-high molecular weight crude oil demulsifier FL-1 (solid content 10%): 4%

[0063] Terpolymer: 35%

[0064] Sodium perfluorononenyloxybenzenesulfonate: 1%

[0065] Butyl Glucoside: 6%

[0066] Polyethyleneimine (n=50): 8%

[0067] Isotridecanyl polyoxyethylene ether (P=7): 2%

[0068] Methylmorpholine: 5%

[0069] Mixed solvent: methanol, dimethylformamide and deionized water (mass ratio 6:3:1) = 39%

[0070] 2. The preparation process of the above-mentioned broad-spectrum aging oil demulsifier:

[0071] 2.1 At room temperature, according to the weight percentage, first put the mixed solvent in the reaction kettle, start stirring, and then stir for about 20 minutes after the dropwise addition, until the sample is transparent.

[0072] 2.2 Continuously add ternary copolyether into the reactor to stir, mix and fully dissolve, then add sodium perf...

Embodiment 3

[0083] 1. A broad-spectrum aging oil demulsifier, consisting of the following components in percentage by weight:

[0084] Ultra-high molecular weight crude oil demulsifier FL-1 (solid content 10%): 7%

[0085] Terpolymer: 28%

[0086] Sodium perfluorooctenyloxybenzenesulfonate: 2%

[0087] Nonyl Glucoside: 4%

[0088] Polyethyleneimine (n=50): 9%

[0089] Isotridecanyl polyoxyethylene ether (P=8): 4%

[0090] Acryloylmorpholine: 4%

[0091] Mixed solvent: methanol, dimethylformamide and deionized water (mass ratio 6:3:1) = 43%

[0092] 2. The preparation process of the above-mentioned broad-spectrum aging oil demulsifier:

[0093] 2.1 At room temperature, according to the weight percentage, first put the mixed solvent in the reaction kettle, start stirring, and then stir for about 10 minutes after the dropwise addition, until the sample is transparent.

[0094] 2.2 Continuously add ternary copolyether into the reactor to stir, mix and fully dissolve, then add sodium pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com