Spar feeding device

A technology of feeding device and spar, which is applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., to achieve the effect of continuous spar orientation and feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

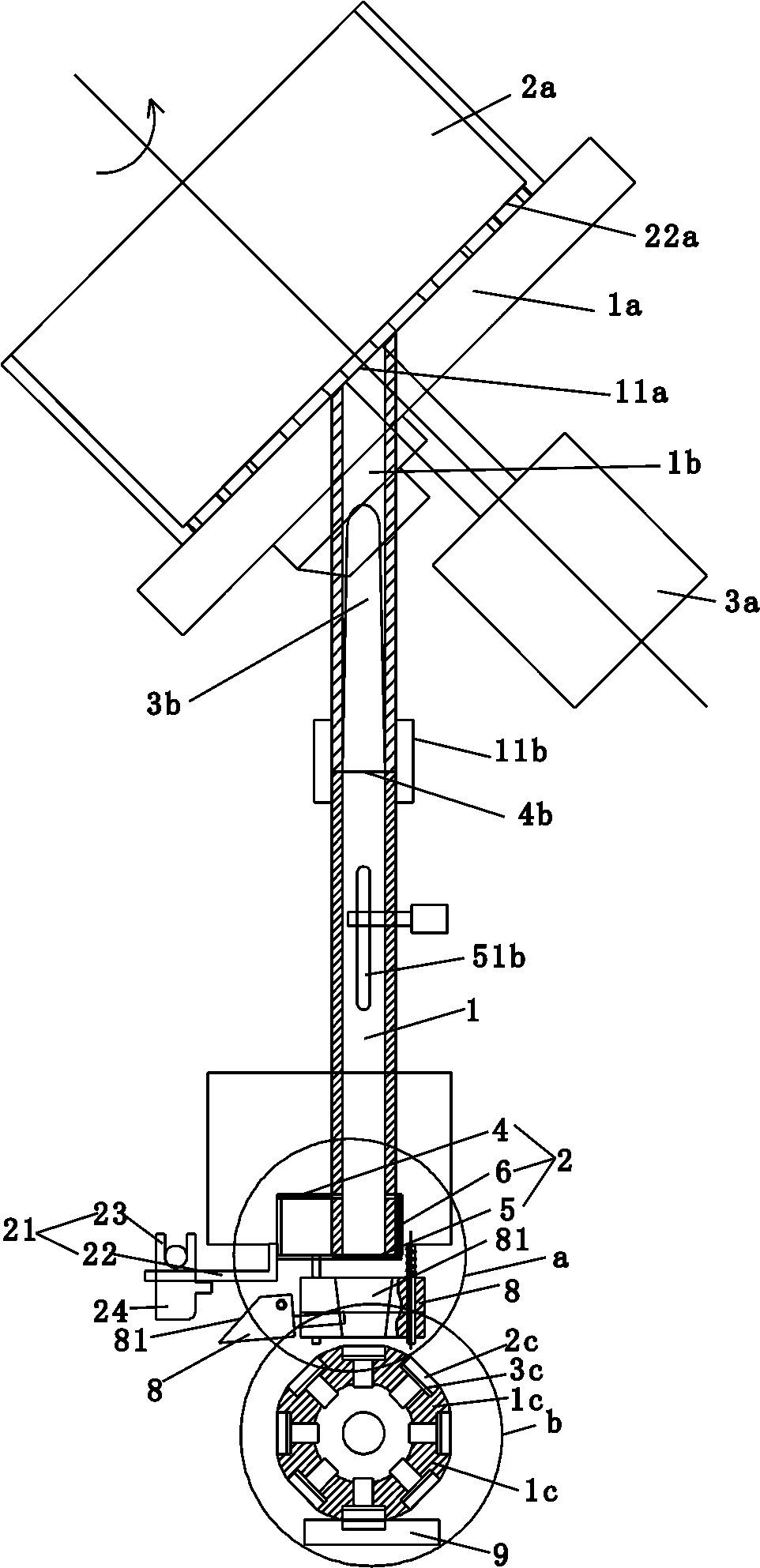

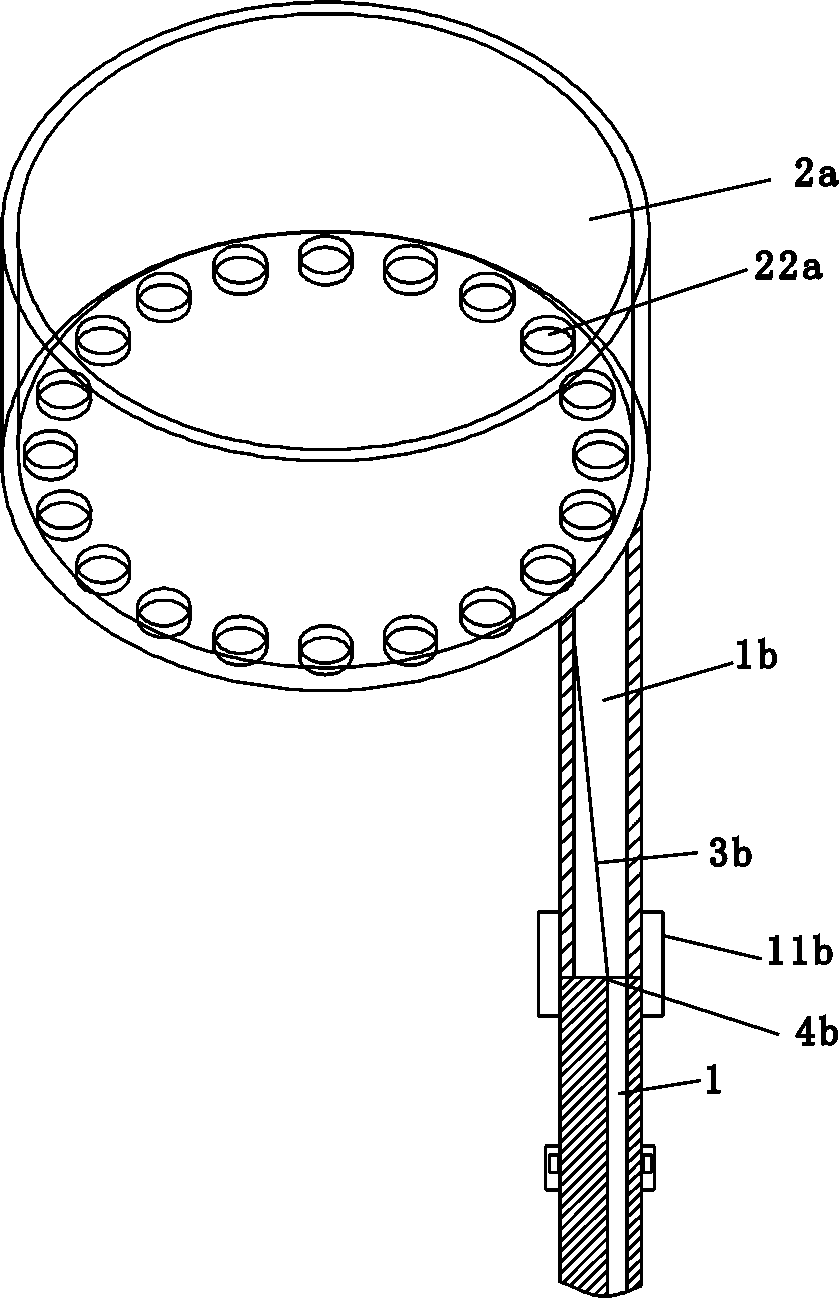

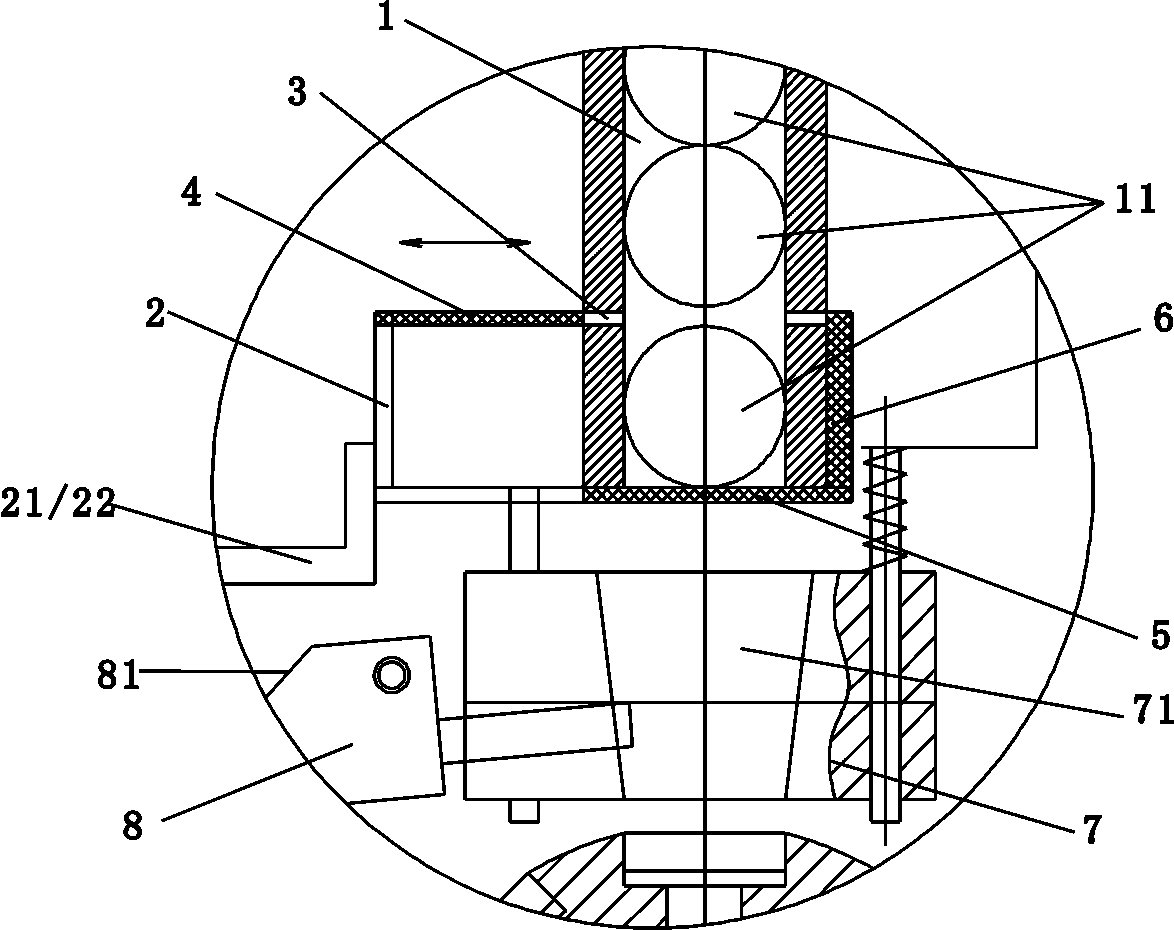

[0030] see Figure 1-11 , This embodiment case includes a spar 11 feeding mechanism, a transfer mechanism, and a delivery mechanism 9. The feeding mechanism includes a feeding tray 2a and a conveying pipe 1b for orienting the spar; The carrier disc 1c or the carrier tape 1d is provided with a carrier hole 2c for carrying 11 crystals on the outer periphery. The carrier disc 1c or the carrier tape 1d rotates intermittently, and the carrier disc 1c or the carrier tape 1d intermittently rotates. 1d, a carrier hole 2c located at the top is exactly aligned with the outlet of the conveying pipe. The delivery mechanism 9 includes a feeding structure that is arranged directly below the carrier disc or the carrier tape, grips the spar from the reclaiming station and sends it out, and the carrier disc that rotates intermittently. Or during the intermittent period of the carrier tape, a carrier hole 2c just below the carrier disc or carrier tape just corresponds to the feeding structure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com