Spar conveying method

A spar, feeding technology, applied in the field of spar feeding, to achieve the effect of continuous orientation and feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

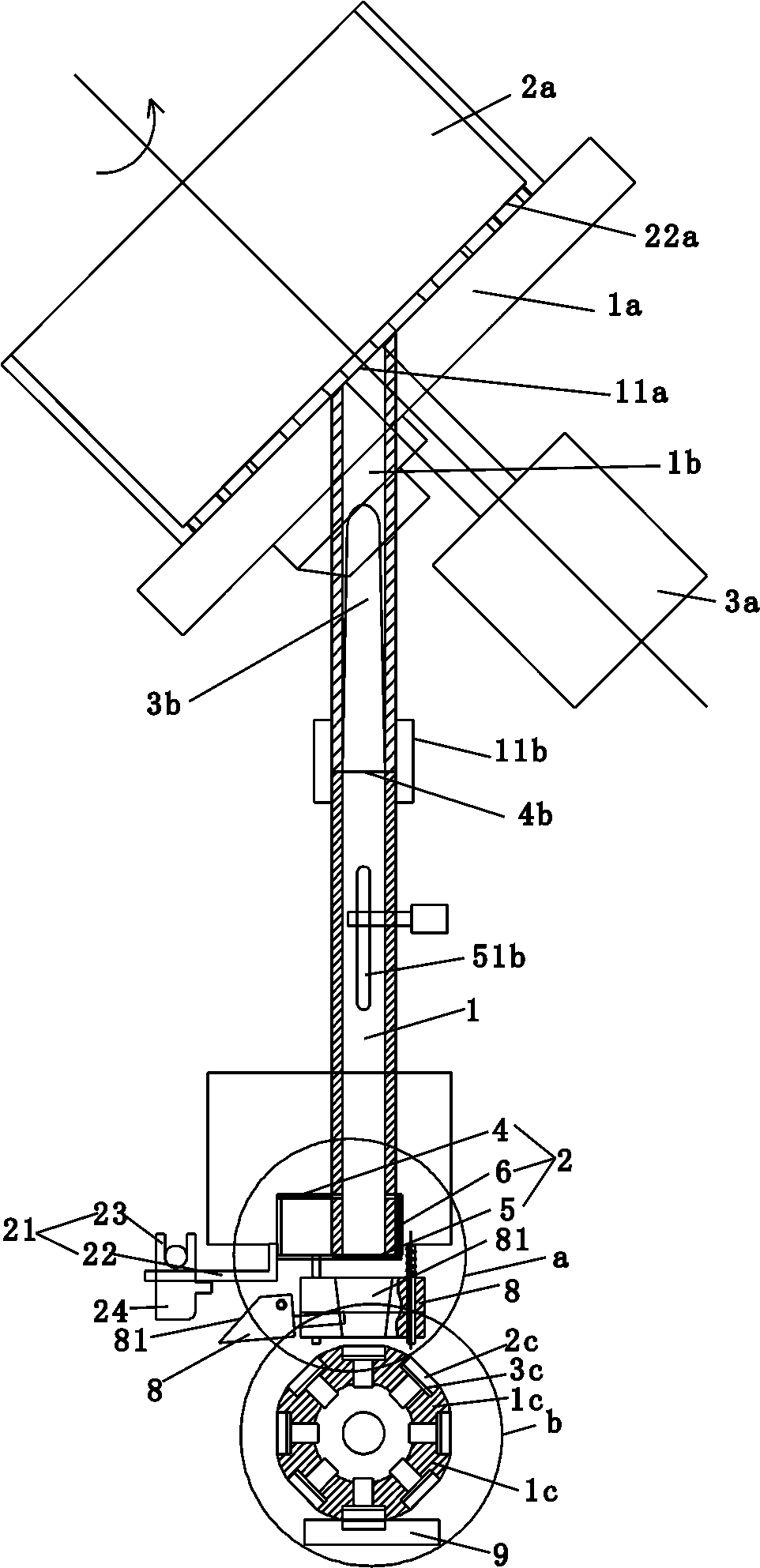

[0029] see Figure 1-11 , this implementation case includes:

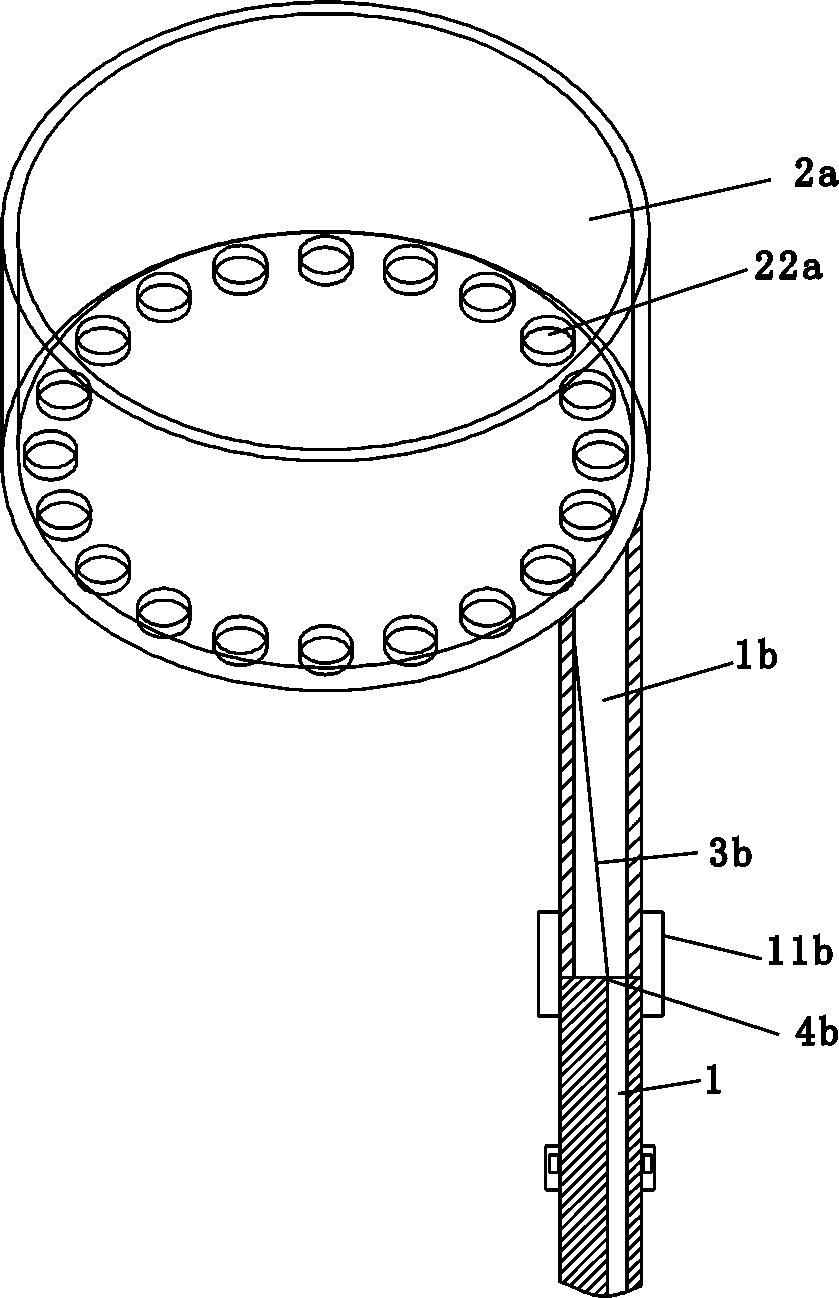

[0030] Step 1: Inject the spar 11 into the delivery pipe provided with the slope 3b for orientation.

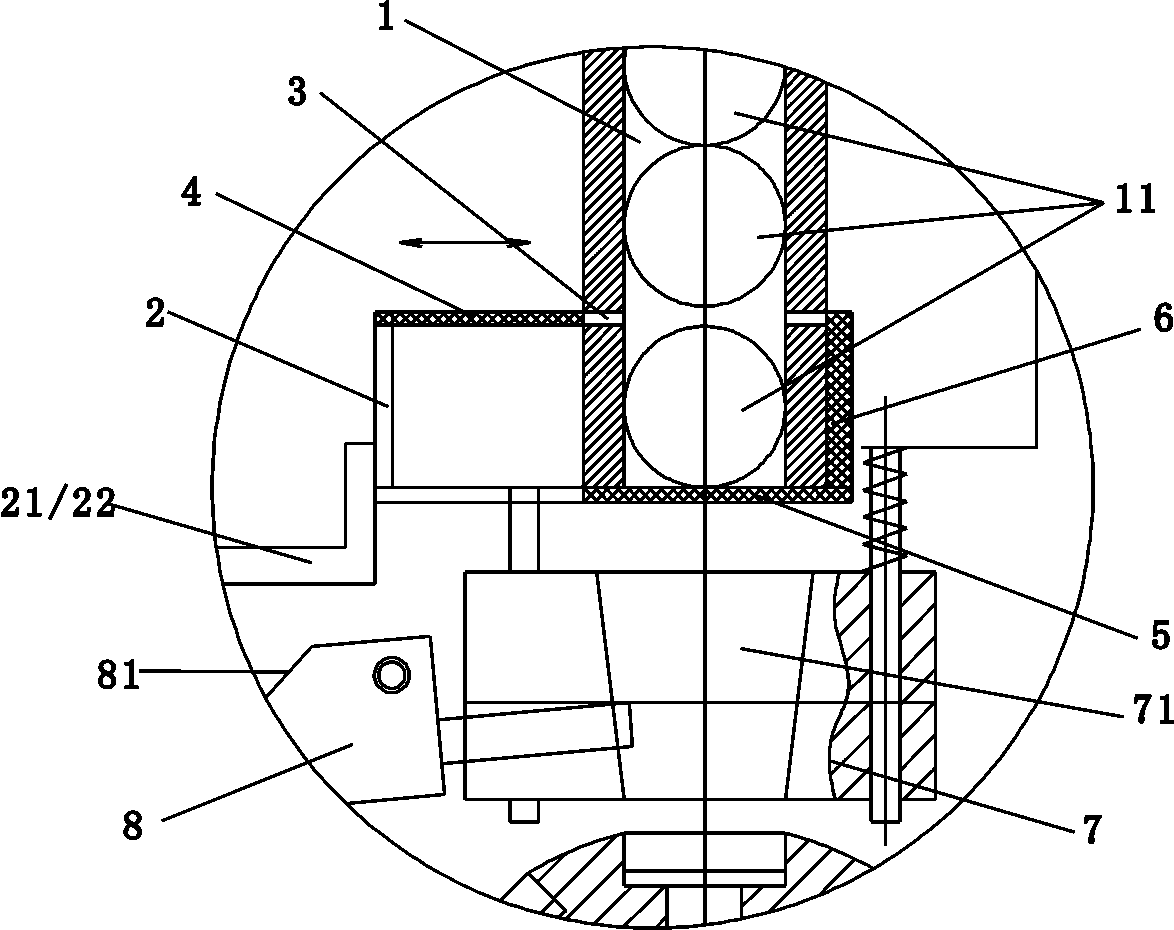

[0031] Step 2, set a gap rotation at the outlet end of the delivery pipe 1b, and set a carrier disc 1c or a carrier belt on the outer periphery for carrying the spar carrying hole 2c, and the oriented spar 11 falls one by one from the outlet end of the delivery pipe 1b into the exactly aligned In the loading hole 2c.

[0032] Step 3: The carrier plate 1c or the carrier tape rotating in the gap rotates to the delivery mechanism 4c located at the appropriate place below, the spar 11 falls or drives the spar 11 to fall into the corresponding position of the delivery mechanism, and passes through the clamping mouth of the delivery mechanism 4c Hold and transport to the appropriate place.

[0033] A reciprocating and sliding transfer block 8 is arranged between the outlet end of the delivery pipe 1b and the carrier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com