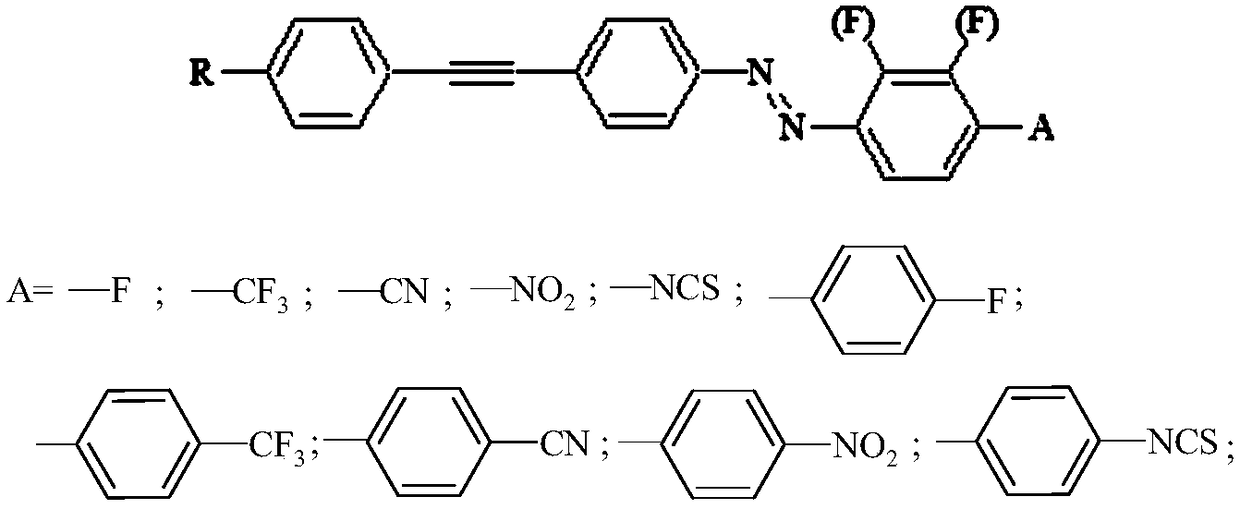

Mixed liquid crystal with huge electrothermal effect being controlled by light and preparation method of mixed liquid crystal

A technology of mixing liquid crystals and thermal effects, which is applied in the preparation of organic compounds, liquid crystal materials, carboxylic acid nitriles, etc., can solve problems such as no access, and achieve the effects of saving energy and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

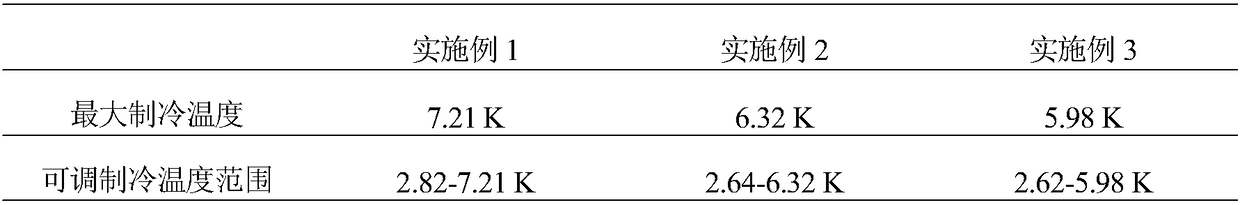

Examples

Embodiment 1

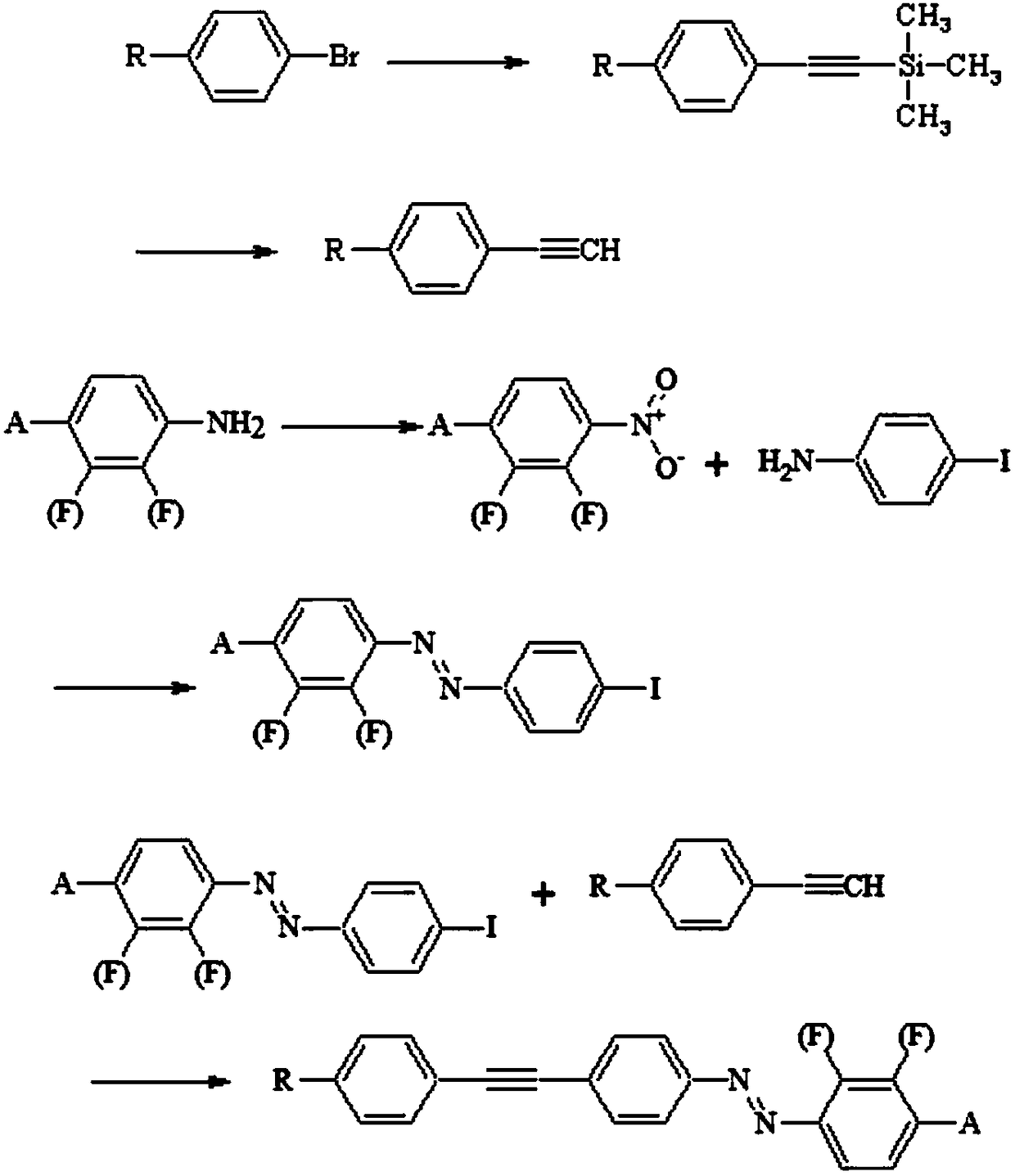

[0025] Embodiment 1, a method for preparing a mixed liquid crystal with light-regulated giant electrothermal effect, comprising the following steps:

[0026] (1) Add 9.8g of dodecylbromobenzene, 120mL of tetrahydrofuran, and 120mL of triethylamine to the first reaction vessel, sonicate for 40min under nitrogen protection, add 0.8g of triphenylphosphine palladium dichloride and 0.4g of iodide Cuprous, then add 6mL trimethylsilylacetylene, the reaction temperature is 80°C, and react for 8h under the protection of nitrogen. After stopping the reaction, remove tetrahydrofuran and triethylamine, dissolve in 50mL methanol and 100mL tetrahydrofuran, and place in the second reactor Then add 24g of potassium carbonate, stir at room temperature for 4h, then remove methanol and tetrahydrofuran, the crude product is purified by column chromatography, the developer is pure petroleum ether, and the first intermediate is obtained;

[0027] (2) Add 8g of p-cyanoaniline and 200mL of dichlorome...

Embodiment 2

[0031] Embodiment 2, a method for preparing a mixed liquid crystal with light-regulated giant electrothermal effect, comprising the following steps:

[0032] (1) Add 5.88g of pentylbromobenzene, 70mL of tetrahydrofuran, and 70mL of triethylamine to the first reaction vessel, sonicate for 40min under nitrogen protection, add 0.48g of triphenylphosphine palladium dichloride and 0.24g of cuprous iodide , then add 3mL trimethylsilylacetylene, the reaction temperature is 30°C, and react for 5h under the protection of nitrogen. After stopping the reaction, remove tetrahydrofuran and triethylamine, dissolve it in 60mL methanol and 120mL tetrahydrofuran, and place it in the second reactor Add 14 g of potassium carbonate, stir at room temperature for 8 hours, then remove methanol and tetrahydrofuran, and purify the crude product by column chromatography with pure petroleum ether as the developer to obtain the first intermediate;

[0033] (2) Add 4.8g of p-cyanoaniline and 120mL of dich...

Embodiment 3

[0037] Embodiment 3, a method for preparing a mixed liquid crystal with light-regulated giant electrothermal effect, comprising the following steps:

[0038] (1) Add 11.76g of butylbromobenzene, 140mL of tetrahydrofuran, and 140mL of triethylamine to the first reaction vessel, sonicate for 40min under nitrogen protection, add 0.96g of triphenylphosphine palladium dichloride and 0.48g of cuprous iodide , then add 2mL trimethylsilylacetylene, the reaction temperature is 60°C, and react for 6h under the protection of nitrogen. After stopping the reaction, remove tetrahydrofuran and triethylamine, dissolve it in 80mL methanol and 160mL tetrahydrofuran, and place it in the second reactor. Add 28g of potassium carbonate, stir at room temperature for 3 hours, then remove methanol and tetrahydrofuran, and purify the crude product by column chromatography, using pure petroleum ether as the developer to obtain the first intermediate;

[0039] (2) Add 9.6g of p-cyanobenzonitrile and 160m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com