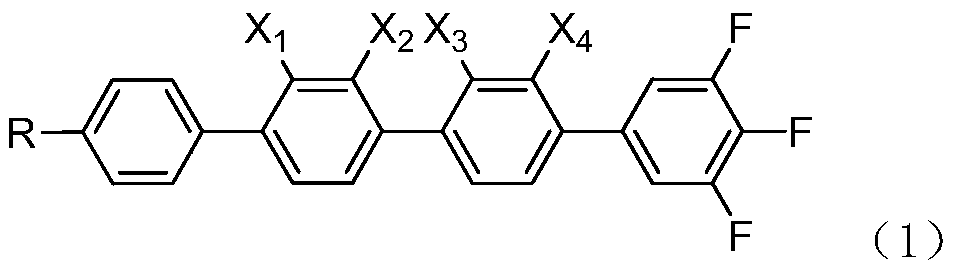

Liquid crystal compound and composition for improving liquid crystal material environmental suitability

A technology of liquid crystal compounds and liquid crystal compositions, applied in the direction of liquid crystal materials, chemical instruments and methods, etc., which can solve the problems of easy crystallization, low solubility, high melting point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

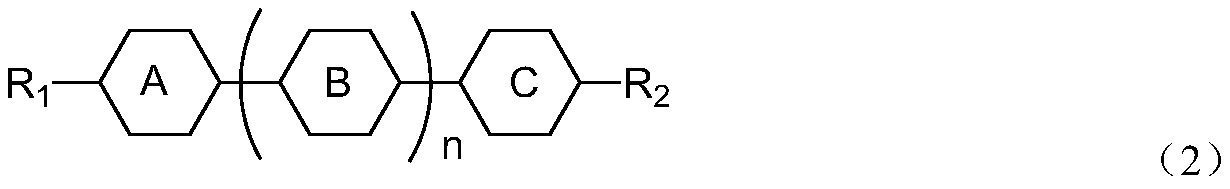

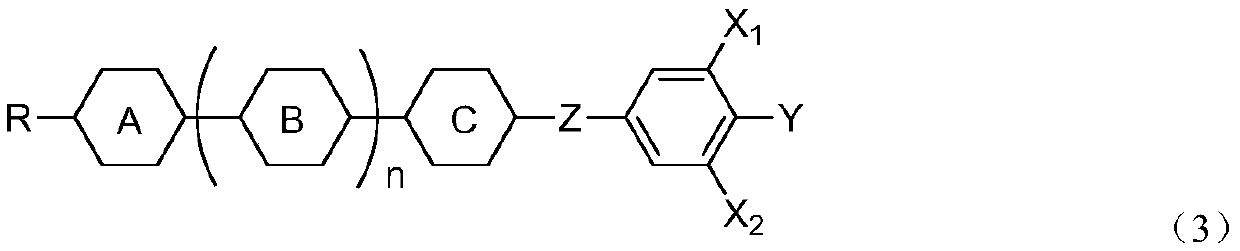

Method used

Image

Examples

Embodiment 1

[0105] Synthesis of 3,4,5-trifluoro-2"-methyl-4"'-pentyl-1,1':4',1":4",1"'-quaterphenyl

[0106] The specific structure is as follows:

[0107]

[0108] The preparation process is as follows:

[0109] Step 1: Synthesis of 4-bromo-3-methyl-4'-pentyl-1,1'-biphenyl

[0110]

[0111] Under the protection of nitrogen, add 4-pentylphenylboronic acid (38.4g, 0.2mol) and 2-bromo-5-iodotoluene successively to a 1L three-neck round-bottomed flask equipped with mechanical stirring, reflux condenser, thermometer, and nitrogen gas guide tube (59.4g, 0.2mol), anhydrous potassium carbonate (82.8g, 0.6mol), tetrabutylammonium bromide (6.4g, 0.02mol), toluene (200mL), ethanol (200mL), water (200mL), and finally Add bis(triphenylphosphine)palladium dichloride (2.1 g, 3 mmol), and replace with nitrogen three times. Turn on the heating, the system rises to an internal temperature of 60°C, keep it warm for 4-6 hours, and then stop the reaction. Cool down to room temperature, let stand to...

Embodiment 2

[0119] Synthesis of 2"-chloro-3,4,5-trifluoro-4"'-propyl-1,1':4',1":4",1"'-quaterphenyl

[0120] The specific structure is as follows:

[0121]

[0122] The preparation process is as follows:

[0123] (1) Synthesis of 4-bromo-3-chloro-4'-propyl-1,1'-biphenyl

[0124]

[0125] Under the protection of nitrogen, add 4-propylphenylboronic acid (27.9g, 0.17mol), 3-chloro-4-bromoiodide in sequence to a 1L three-necked round-bottomed flask equipped with mechanical stirring, reflux condenser, thermometer, and nitrogen gas guide tube. Benzene (54g, 0.17mol), anhydrous potassium carbonate (70.4g, 0.51mol), tetrabutylammonium bromide (5.5g, 0.017mol), toluene (180mL), ethanol (180mL), water (180mL), and finally Bis(triphenylphosphine)palladium dichloride (1.2 g, 1.7 mmol) was added and replaced with nitrogen three times. Turn on the heating, reflux for 4 to 6 hours, and stop the reaction. Cool down to room temperature, stand to separate layers, extract the aqueous phase with to...

Embodiment 3

[0136] Synthesis of 2"-chloro-2',3,4,5-tetrafluoro-4"'-propyl-1,1':4',1":4",1"'-quaterphenyl

[0137] The specific structure is as follows:

[0138]

[0139] 4'-bromo-3,4,5-trifluoro- 1,1'-biphenyl, the target compound 2"-chloro-2', 3,4,5-tetrafluoro-4"'-propyl-1 can be synthesized according to the same method,

[0140] 1': 4', 1": 4", 1"'-quaterphenyl.

[0141] Structural identification data: 1 H NMR (δ, CDCl 3 ): 7.726~7.723(m, 1H), 7.568~7.528(m, 3H), 7.467~7.403(m, 2H), 7.375~7.324(m, 2H), 7.297~7.241(m, 4H), 2.666~2.635 (t, 2H, J=7.5Hz), 1.733~1.658 (m, 2H), 0.999~0.970 (t, 3H, J=7Hz).

[0142] MS (70eV) m / z (%): 456.2 (26.9), 455.3 (22.65), 454.3 (M + , 75.14), 427.2 (35.83), 426.2 (28.87), 425.2 (100), 389.2 (15.31), 212.6 (43.45).

[0143] The above structural identification data show that the synthesized compound is indeed the compound 2"-chloro-2',3,4,5-tetrafluoro-4"'-propyl-1,1':4',1":4" , 1"'-quaterphenyl.

[0144] The phase transition temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com