Nematic liquid crystal compound and applications thereof

A liquid crystal compound and compound structure technology, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of low voltage, fast TFT-LCD response, and low charge retention, and achieve stable properties and mutual solubility. Good, large dielectric anisotropy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

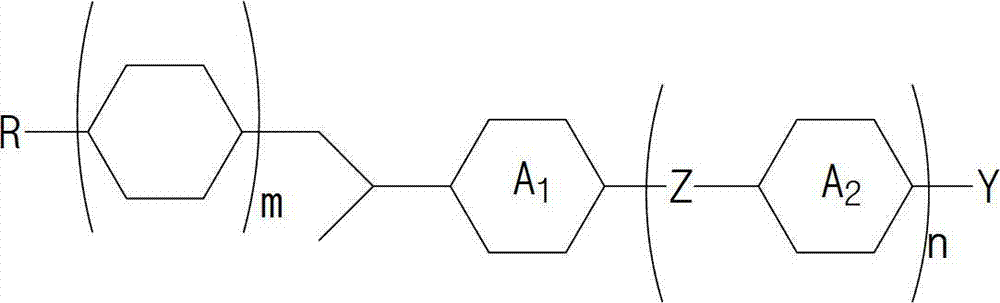

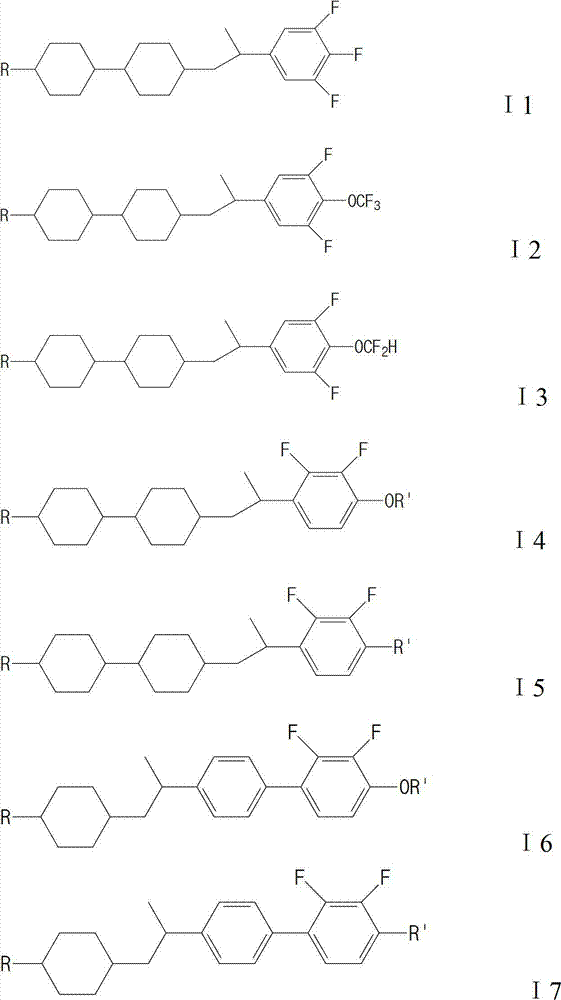

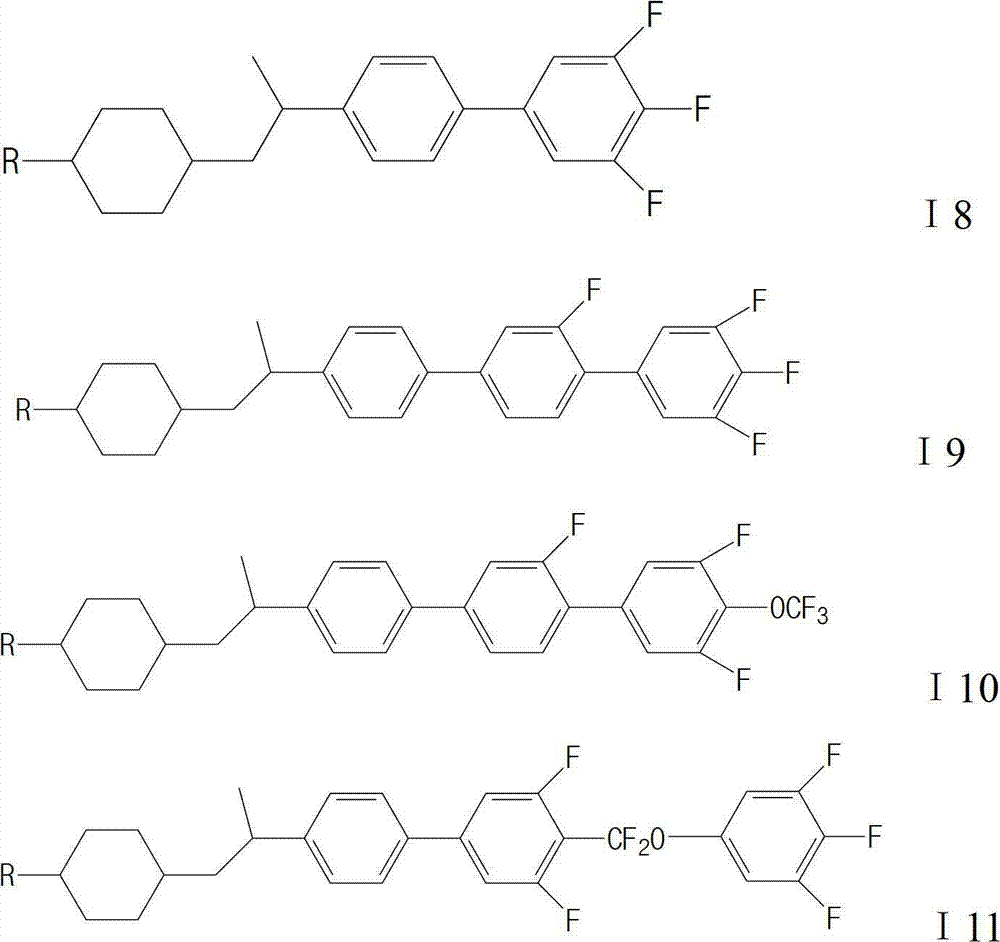

Method used

Image

Examples

Embodiment 1

[0039] Synthesis of 5-(4-propylbicyclohexyl)acetyl-1,2,3-trifluorobenzene

[0040]

[0041] Add 0.48 moles of magnesium chips and 200 milliliters of tetrahydrofuran (THF) successively in the there-necked flask, heat to reflux, add dropwise 20 milliliters of 4-propyl bicyclohexyl methyl bromide and 100 milliliters of tetrahydrofuran (THF) to initiate the reaction. Add the remaining solution dropwise at ℃, continue to reflux for 1 hour, and then add dropwise a solution composed of 0.4 moles of 3,4,5-trifluorobenzonitrile and 300 ml of toluene at 70°C, and reflux for 4 hours after the dropwise addition. Add 500 ml of 2M hydrochloric acid to reflux for 2 hours, separate the liquid, wash with water until neutral, evaporate the solvent, and recrystallize with 4 times absolute ethanol to obtain 106.0 g of A1 as a white solid. The gas phase purity is 99.0%.

[0042] Synthesis of 1-(4-propylbicyclohexyl)-2-(3,4,5-trifluorophenyl)propane

[0043]

[0044] Add 0.2 mole of methylt...

Embodiment 2

[0049] 1-(4-Propylcyclohexyl)-2-(4-bromophenyl)propane (B3).

[0050] Synthesis of 1-(4-propylcyclohexyl)-2-(3’,4’,5’-trifluorobiphenyl)propane

[0051]

[0052]Add 0.1 mol of 1-(4-propylcyclohexyl)-2-(4-bromophenyl)propane (B3), 0.12 mol of 3,4,5-trifluorophenylboronic acid, 50 ml of anhydrous Ethanol, 100 ml of toluene and 100 ml of water, start stirring, add 0.24 moles of anhydrous sodium carbonate, heat to 60 ° C and then add 0.05 mmol of tetrakis (triphenylphosphine) palladium, heat and reflux for four hours, cool to 50 ° C, Add 0.4L of toluene and stir for 5 minutes, let stand for 10 minutes, and separate the liquids. The upper layer was the product phase, which was washed three times with 0.2L×3 water, and the solvent was distilled off to obtain a light yellow solid, which was recrystallized twice from absolute ethanol to obtain a white crystal (C1), with a quantity of 32 grams and a gas phase purity of 99.5%.

Embodiment 3

[0056] Application of liquid crystal compounds containing isopropane bridges in TN, IPS, FFS, ADS-TFT modes:

[0057] The liquid crystal composition was prepared in parts by weight shown in Table 1, and the performance parameters of the liquid crystal composition were shown in Table 1.

[0058] Table 1, parts by weight and performance parameters of each component in the liquid crystal composition

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com