Graphene reinforced ceramic matrix composite material and preparation method thereof

A composite material and graphene technology, applied in ceramic forming machines, manufacturing tools, etc., can solve problems such as easy agglomeration and inconspicuous toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

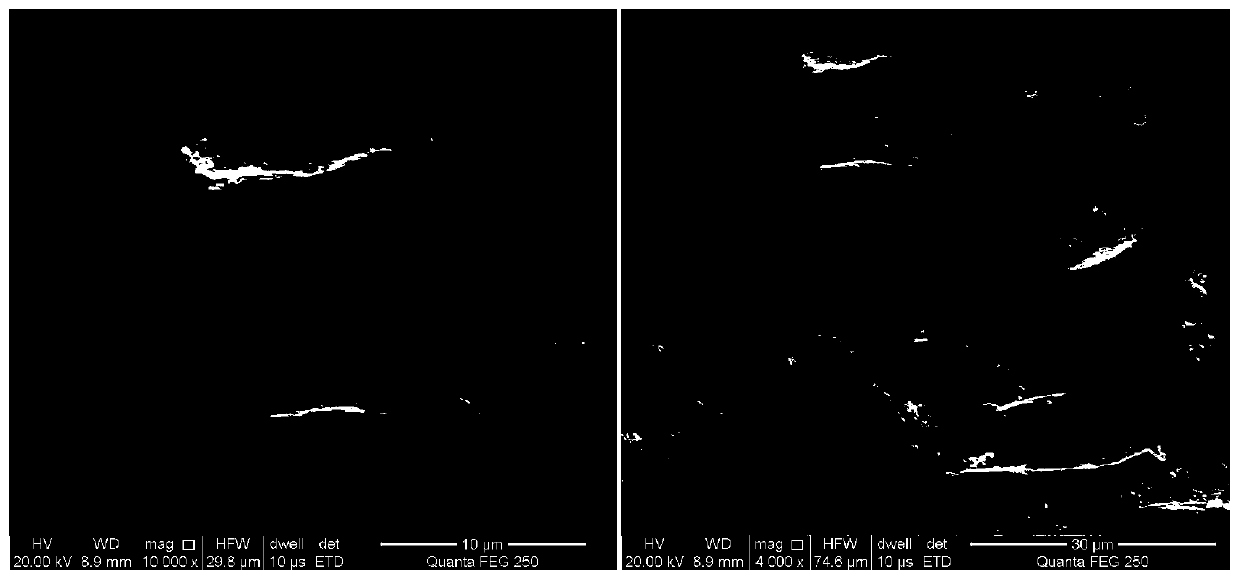

Image

Examples

Embodiment 1

[0038] Embodiment 1 (graphene 0.5vol%%)

[0039] Take graphene, bisphenol A epoxy acrylate (BAEA), trimethylolpropane triacrylate (TMPTA), tripropylene glycol diacrylate (TPGDA), isobornyl methacrylate (IBMA), initiator Diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide (TPO), placed in a high-speed vacuum stirring defoamer machine and stirred evenly at a speed of 1800 rap for 3 minutes. Then use ultrasonic vibration to solve the problem of graphene agglomeration, power 100%, time 90min, degassing to obtain a premix, add powder ZrO to the premix 2 , PVP is stirred evenly in a high-speed vacuum stirring and defoaming agent machine, the speed is 1800, and the time is 3 minutes. Mix well to get the ceramic slurry,

[0040] The addition amount of each component in the ceramic slurry is as follows:

[0041]

[0042] Use the component slurry to perform light-curing molding. During the curing molding process, the thickness of the slice layer is 20 μm, and the time is 20 s;

[0...

Embodiment 2

[0044] Embodiment 2 (graphene 0.125vol%)

[0045] Take graphene, bisphenol A epoxy acrylate (BAEA), trimethylolpropane triacrylate (TMPTA), tripropylene glycol diacrylate (TPGDA), isobornyl methacrylate (IBMA), initiator Diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide (TPO), placed in a high-speed vacuum stirring defoamer machine and stirred evenly at a speed of 1800 rap for 3 minutes. Then use ultrasonic vibration to solve the problem of graphene agglomeration, power 100%, time 90min, degassing to obtain a premix, add powder ZrO to the premix 2 , PVP is stirred evenly in a high-speed vacuum stirring and defoaming agent machine, the speed is 1800, and the time is 3 minutes. Mix well to get the ceramic slurry,

[0046] The addition amount of each component in the ceramic slurry is as follows:

[0047]

[0048]

[0049] The composition slurry is used for photocuring molding. During the curing molding process, the thickness of the slice layer is 20 μm, and the time is ...

Embodiment 3

[0050] Embodiment 3 (graphene 0.25vol%)

[0051] Take bisphenol A epoxy acrylate (BAEA), trimethylolpropane triacrylate (TMPTA), tripropylene glycol diacrylate (TPGDA), isobornyl methacrylate (IBMA), diphenyl (2 , 4,6-trimethylbenzoyl) phosphine oxide (TPO), graphene stirring, defoaming to obtain a premix, ultrasonic dispersion and deagglomeration, adding powder ZrO to the premix 2 , PVP and mix to obtain ceramic slurry.

[0052] The addition amount of each component in the ceramic slurry is as follows:

[0053] BAEA: 2.00g

[0054] TMPTA: 2.00g

[0055] TPGDA: 3.00g

[0056] IBMA: 4.50g

[0057] TPO: 0.2000g

[0058] ZrO2: 30.0000g

[0059] PVP: 0.1500g

[0060] Graphene 0.027g

[0061] The composition slurry is used for photocuring molding. During the curing molding process, the thickness of the slice layer is 50 μm, and the curing time is 20s. Degreasing-sintering is carried out in an air atmosphere. / min to 300°C, keep warm for 120min, 1.0°C / min to 500°C, keep wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com