Methods and production system for laminating interior components in vehicles

A technology for production systems and interior parts, applied in the bonding method of adhesive heating, vehicle parts, lamination systems, etc., can solve problems that affect corporate profits and investment, and achieve simple orientation, less time-consuming, and high beats Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

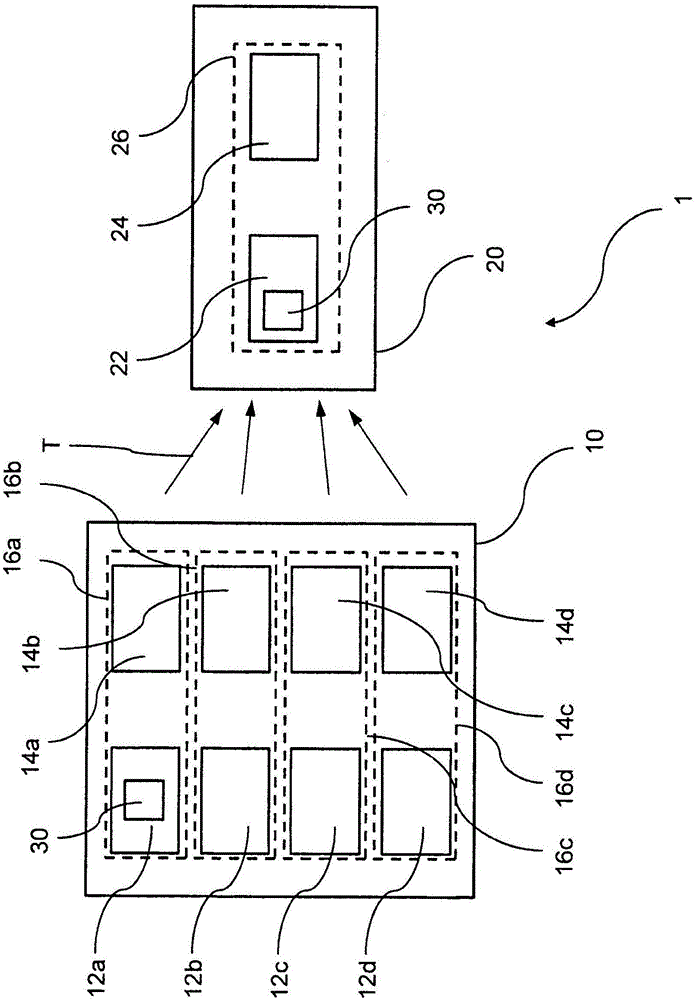

[0031] figure 1The structure of an embodiment of the production system 1 according to the invention is shown schematically. The production system 1 is divided into a first production section 10 and a second production section 20 . In the first production area 10 , the gluing elements (not shown in this figure) for gluing the interior trim are prepared, while in the second production area 20 the gluing elements are permanently fixed to the interior trim.

[0032] The first production space 10 has four workstations working in parallel for each individual process to be carried out of the first main process. Four supply stations 12a, 12b, 12c, 12d are provided for the supply process of the glued elements. Depending on requirements, carrier elements and adhesives can also be provided in the supply stations 12a, 12b, 12c, 12d. This depends in particular on whether the gluing elements have already been applied to the interior trim in the first production area 10 (alternative 1) or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com