Improved method for preparing superfine high length-diameter-ratio anhydrous calcium sulfate crystal whiskers by using hydrothermal process

A technology of calcium sulfate anhydrous and calcium sulfate hemihydrate, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problems of poor product morphology and long hydrothermal reaction time, and achieve uniform morphology , The effect of promoting fast directional arrangement and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

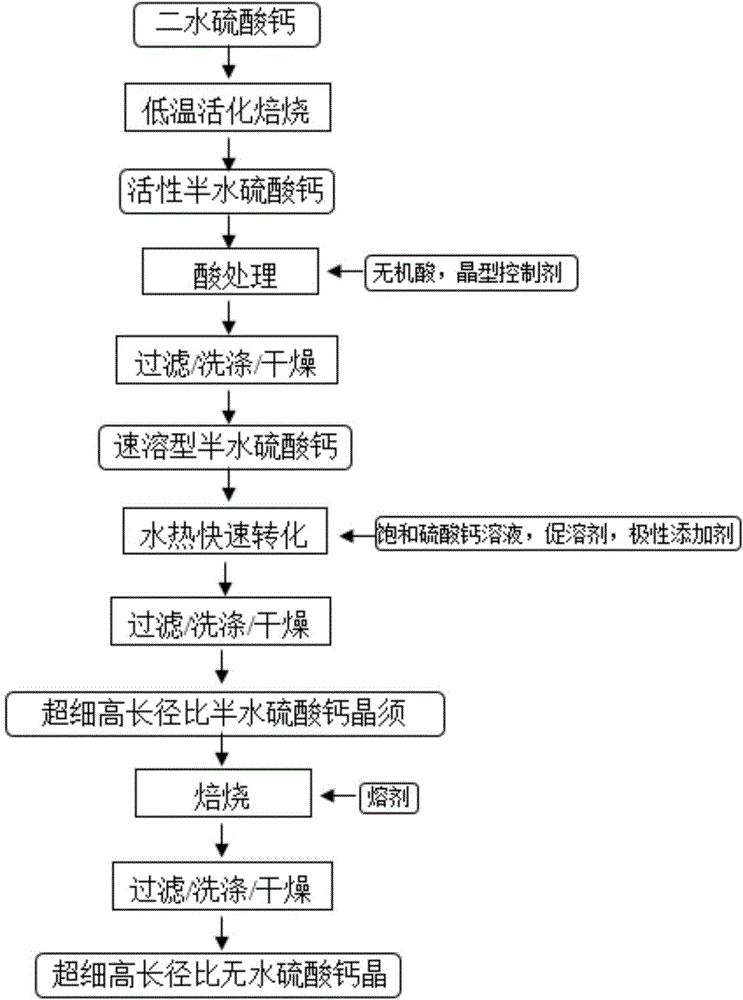

Method used

Image

Examples

Embodiment 1

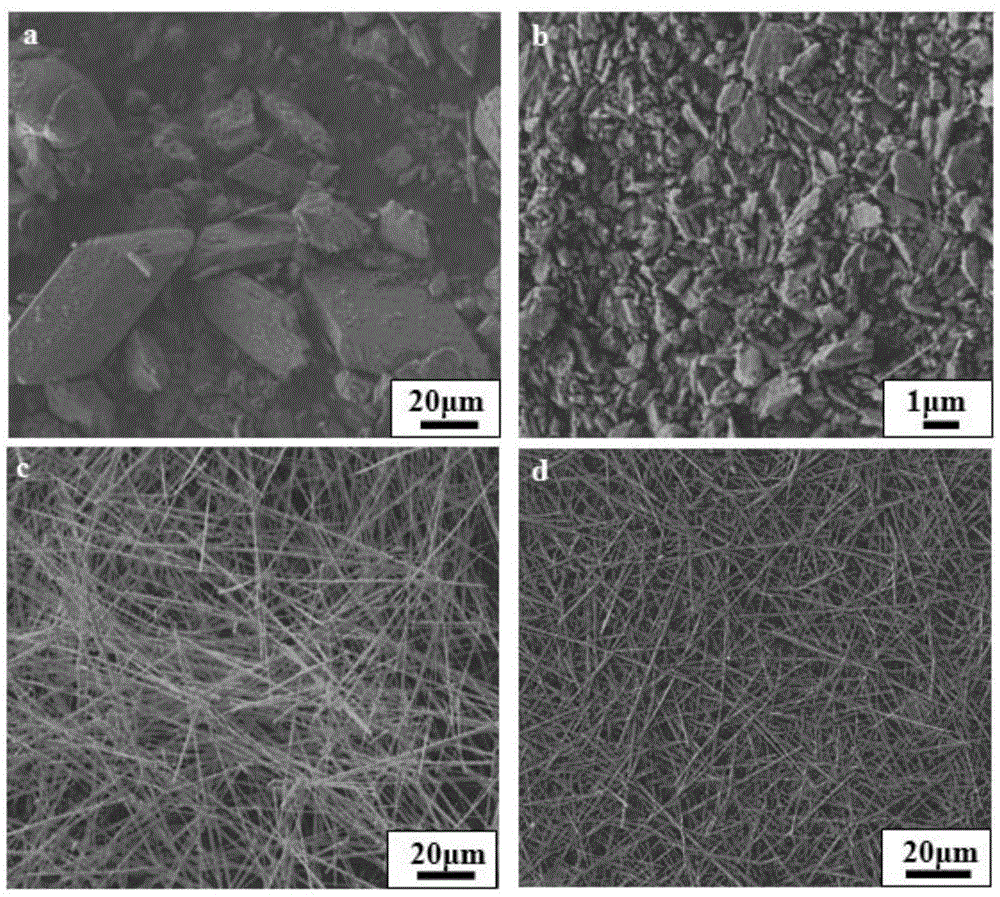

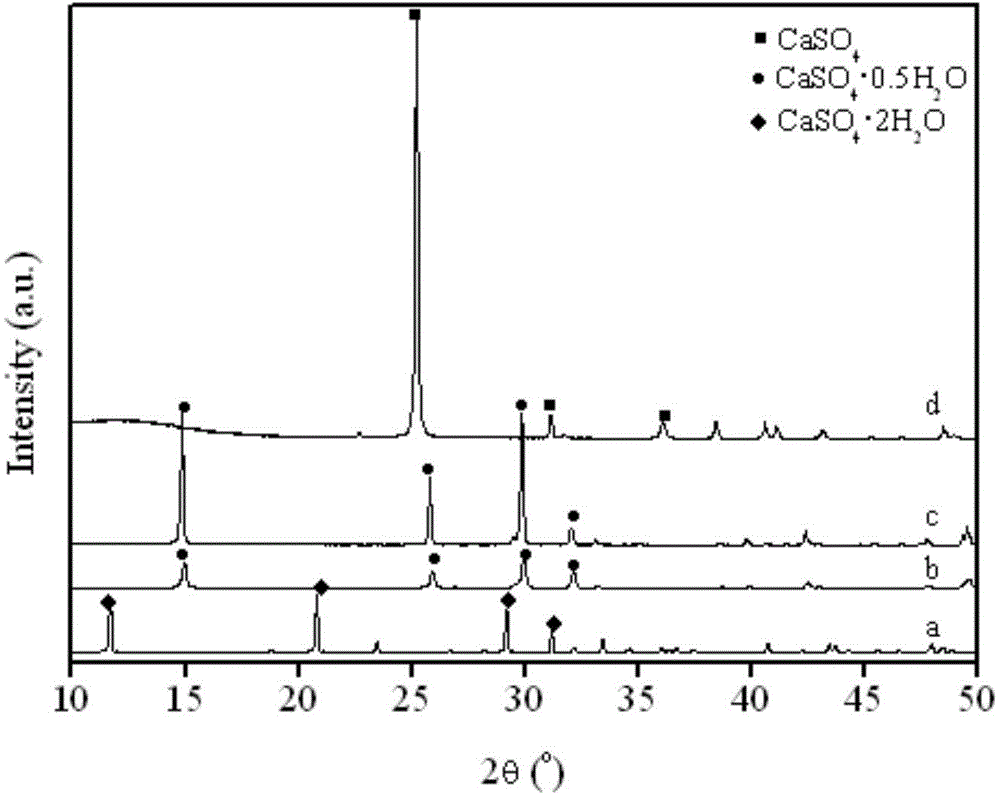

[0028] Weigh 100 grams of calcium sulfate dihydrate (main content 95wt%, particle size less than 150 mesh) and place in a muffle furnace, roast at a constant temperature of 100°C for 6 hours to obtain active calcium sulfate hemihydrate; add active calcium sulfate hemihydrate containing 0.5wt % hydrochloric acid, 0.1wt% magnesium sulfate aqueous solution, made into a suspension with a solid content rate of 0.5wt%, reacted for 1 hour at 10°C under stirring (50 rpm), filtered, washed and dried at 80°C for 1 hour hour, obtain instant calcium sulfate hemihydrate; instant calcium sulfate hemihydrate is added to the saturated calcium sulfate solution containing 0.0001wt% sodium ethylenediamine tetraacetate, 0.001wt% sodium fluoride, and the solid content rate is made into 0.1wt%. The suspension was hydrothermally reacted at 100°C and stirred (250 rpm) for 2 minutes, cooled, filtered, washed, and dried (80°C, 1 hour) to obtain a main content of 95wt%, a diameter of 10 μm, and a length ...

Embodiment 2

[0030] Weigh 100 grams of calcium sulfate dihydrate (main content 99wt%, particle size less than 150 mesh) and place in a muffle furnace, and roast at a constant temperature of 180°C for 1 hour to obtain active calcium sulfate hemihydrate; add active calcium sulfate hemihydrate containing 50wt% The aqueous solution of sulfuric acid and 20wt% magnesium nitrate was made into a suspension with a solid content rate of 50wt%, reacted at 80°C under stirring (500 rpm) conditions for 1 hour, filtered and washed and dried at 110°C for 1 hour to obtain Instant calcium sulfate hemihydrate; Instant calcium sulfate hemihydrate is added to the saturated calcium sulfate solution containing 1wt% sodium dodecylsulfonate, 5wt% potassium fluoride to make a suspension with a solid content rate of 25wt%. 200 ° C, stirring (500 rpm) under the condition of hydrothermal reaction for 20 minutes, cooling, filtering, washing, drying (110 ° C, 6 hours), to obtain a main content of 99.2wt%, a diameter of 5...

Embodiment 3

[0032] Weigh 100 grams of calcium sulfate dihydrate (main content 96.4wt%, particle size less than 150 mesh) and place in a muffle furnace, and roast at a constant temperature of 150°C for 3 hours to obtain active calcium sulfate hemihydrate; add active calcium sulfate hemihydrate containing 20wt % nitric acid, 5wt% magnesium chloride aqueous solution, made into a suspension with a solid content rate of 10wt%, reacted for 4 hours at 50°C under stirring (250 rpm) conditions, filtered, washed and dried at 100°C for 5 hours to obtain Instant calcium sulfate hemihydrate; add instant calcium sulfate hemihydrate to a saturated calcium sulfate solution containing 0.1wt% sodium dodecylbenzenesulfonate and 1wt% ammonium fluoride to make a suspension with a solid content of 10wt%. , hydrothermal reaction at 140°C, stirring (150 rpm) for 10 minutes, cooling, filtering, washing, and drying (105°C, 4 hours), to obtain a main content of 97wt%, a diameter of 0.005μm, a length of 50μm, and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com