Controllable preparation method of ultrathin anhydrous calcium sulfate crystal whisker with high length-diameter ratio

A technology of calcium sulfate anhydrous and calcium sulfate hemihydrate, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problems of complex microemulsion preparation process, poor product morphology, harsh process conditions, etc. To achieve the effect of high added value, uniform morphology and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

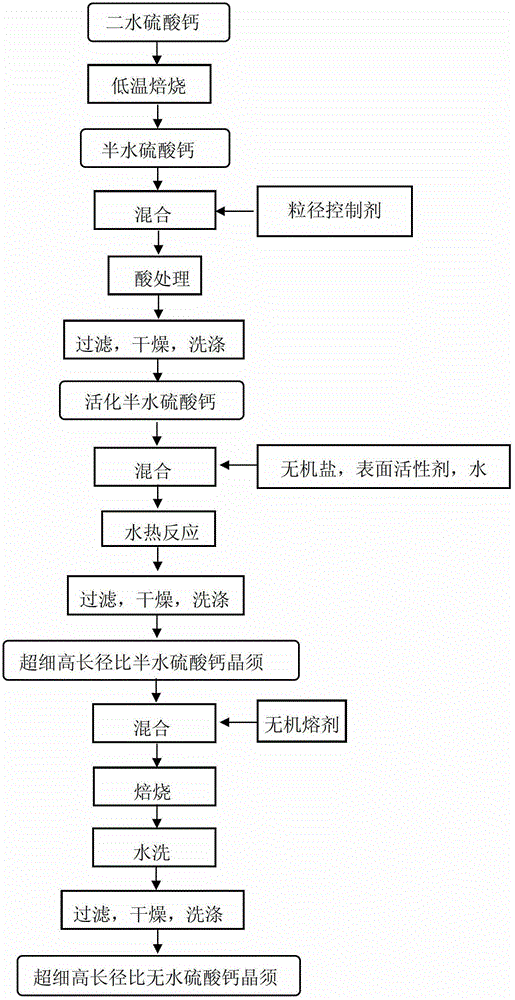

Method used

Image

Examples

Embodiment 1

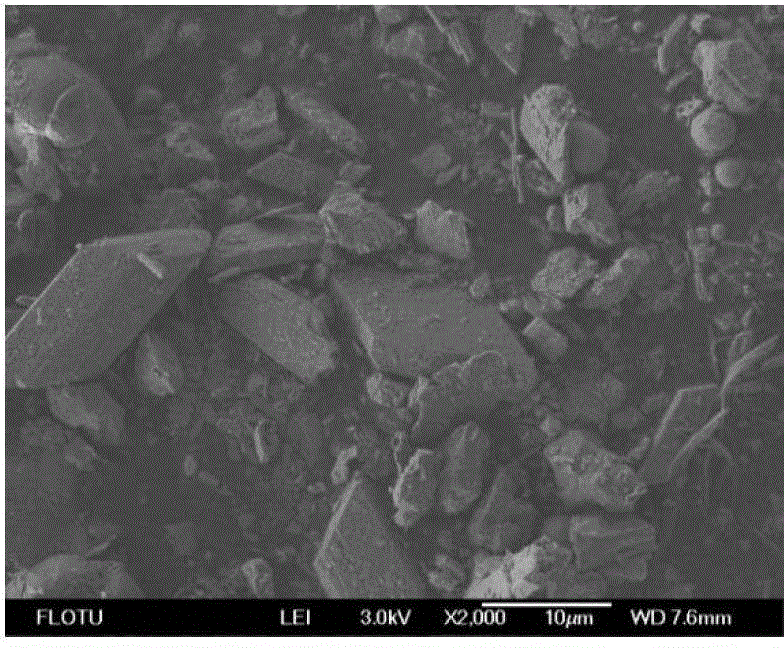

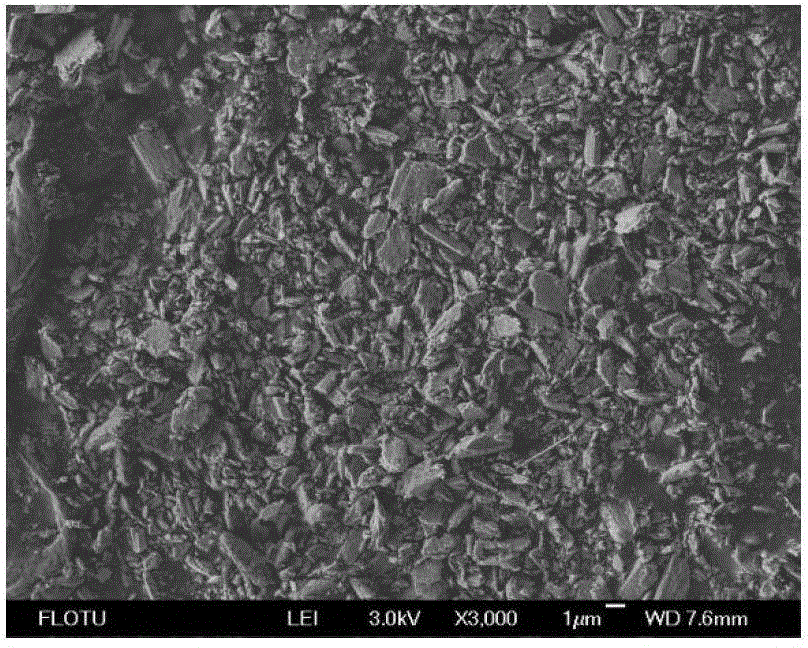

[0035] Weigh 100 grams of calcium sulfate dihydrate (main content 95wt%, particle size 150 mesh) and place it in a muffle furnace, heat up (1°C / min) to 120°C and roast at a constant temperature for 6 hours to obtain active calcium sulfate hemihydrate; Add 0.5wt% sulfuric acid solution to calcium sulfate water and sodium stearate to make a suspension with a solid content of 0.5wt% and a sodium stearate concentration of 0.001mol / L, stir at 10°C (50 rpm) Under the condition of reaction for 0.5 hours, after filtration and washing, dry at 80°C for 1 hour to obtain superfine and highly active calcium sulfate hemihydrate; combine superfine and highly active calcium sulfate hemihydrate with a total molar concentration of 0.001mol / L inorganic salt and surface active solution (the molar ratio of sodium chloride to cetyltrimethylammonium bromide is 1:0.1) was added into the autoclave to make a suspension with a solid content of 0.1wt%, and stirred at 100°C (250 rpm Hydrothermal reaction ...

Embodiment 2

[0037] Take by weighing calcium sulfate dihydrate (main content 99.995wt%, particle size 500 orders) 100 grams and place muffle furnace, heat up (25 DEG C / min) to 180 DEG C and then roast at a constant temperature for 1 hour to obtain active calcium sulfate hemihydrate; Add 50wt% hydrochloric acid solution to calcium sulfate hemihydrate and sodium stearate to make a suspension with a solid content rate of 50wt% and a sodium stearate concentration of 1mol / L. React for 6 hours, filter, wash and dry at 110°C for 6 hours to obtain superfine high-activity calcium sulfate hemihydrate; the superfine high-activity calcium sulfate hemihydrate and total molar concentration are 1mol / L inorganic salt and surfactant solution ( Potassium chloride and sodium dodecylbenzene sulfonate molar ratio is 1:10) into the autoclave to make a suspension with a solid content rate of 25wt%, and hydrothermally React for 10 hours, cool, filter, wash, dry (110 DEG C, 6 hours), obtain the calcium sulfate hem...

Embodiment 3

[0039] Take by weighing 100 grams of calcium sulfate dihydrate (main content 98.5wt%, particle size 250 orders) and place in a muffle furnace, heat up (10°C / min) to 160°C and roast at a constant temperature for 2 hours to obtain active calcium sulfate hemihydrate; Calcium sulfate hemihydrate and sodium dodecylbenzene sulfonate are added into 25wt% nitric acid solution to make a suspension with a solid content rate of 50wt% and a concentration of sodium dodecylbenzenesulfonate of 1mol / L. (300 rev / min) conditions, reacted for 2 hours, filtered, washed and dried at 100°C for 4 hours to obtain superfine and highly active calcium sulfate hemihydrate; Inorganic salt and surfactant (magnesium chloride and cetyl sodium sulfate molar ratio is 1:1) solution are added into autoclave, make the suspension of solid content rate 15wt%, at 150 ℃, stirring (100 rpm ) under the condition of hydrothermal reaction for 4 hours, cooling, filtering, washing, and drying (90° C., 2 hours), to obtain c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com