Screw compressor

一种螺旋压缩机、压缩机壳体的技术,应用在螺旋压缩机领域,达到易激活的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

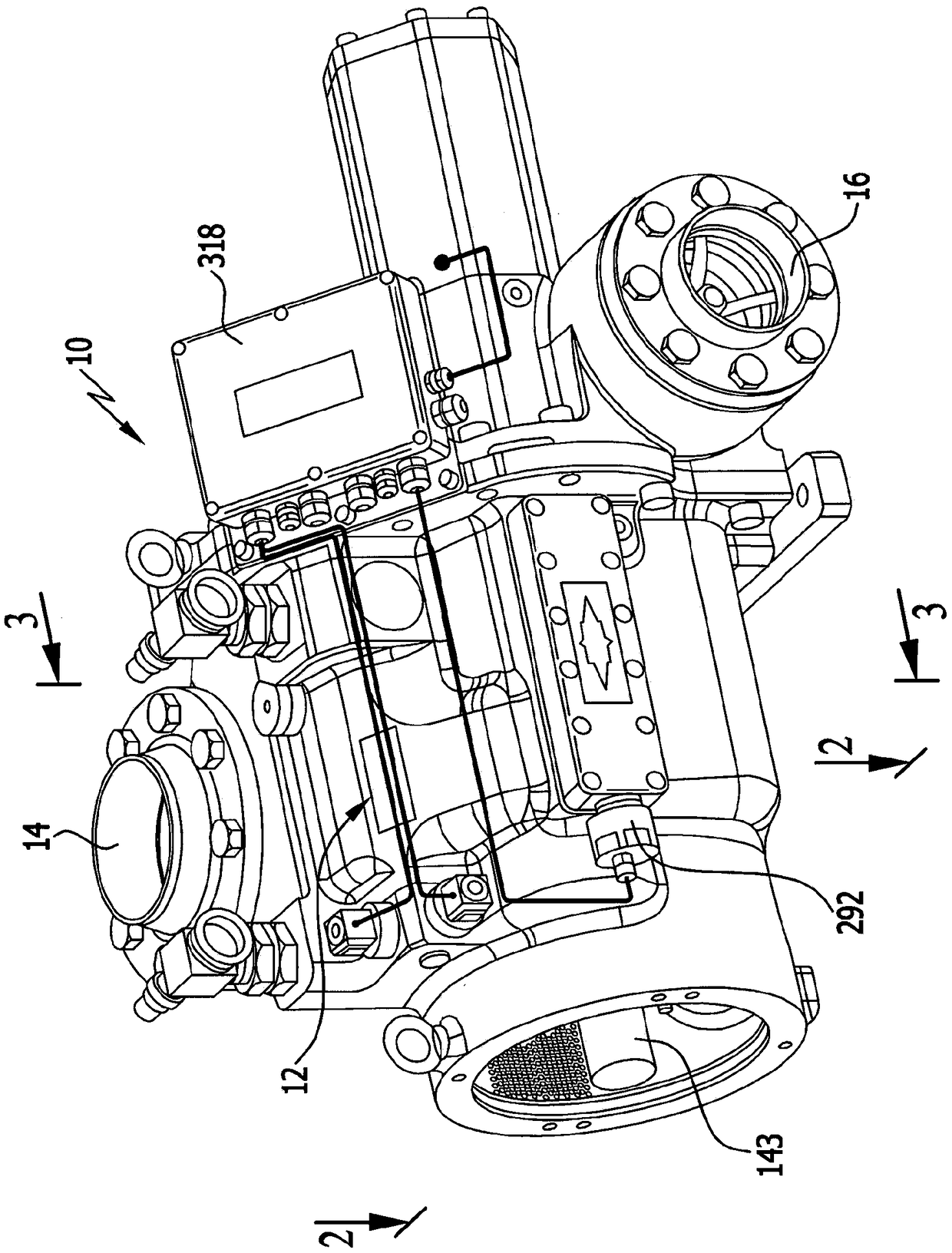

[0058] figure 1 The screw compressor 10 according to the invention of the embodiment shown in includes a compressor housing indicated as a whole by 12, which has a suction connection 14 and a pressure connection 16, through which the suction to be sucked The gaseous medium, especially the refrigerant, is discharged via the pressure connection to the gaseous medium, especially the refrigerant, which is compressed to high pressure.

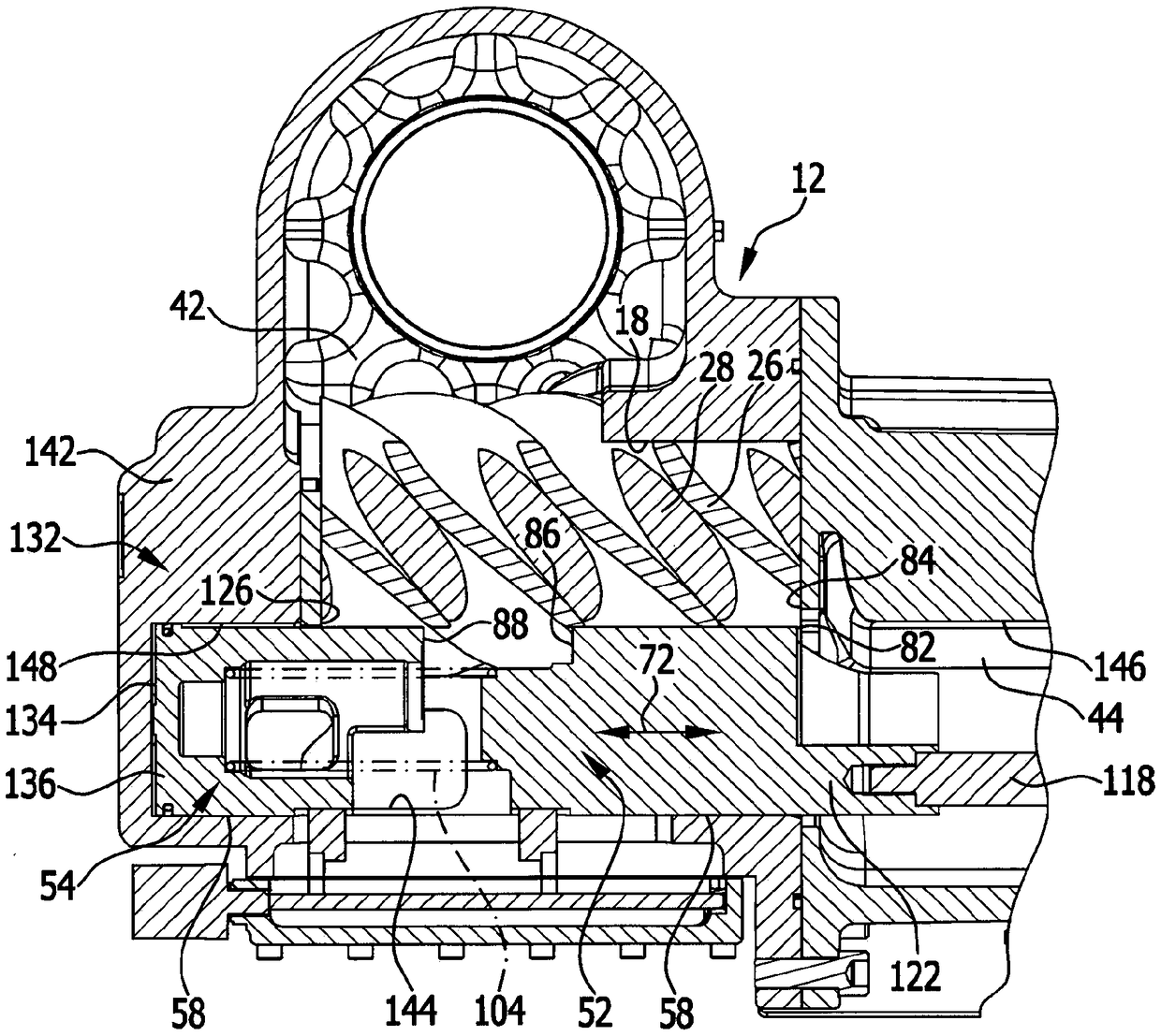

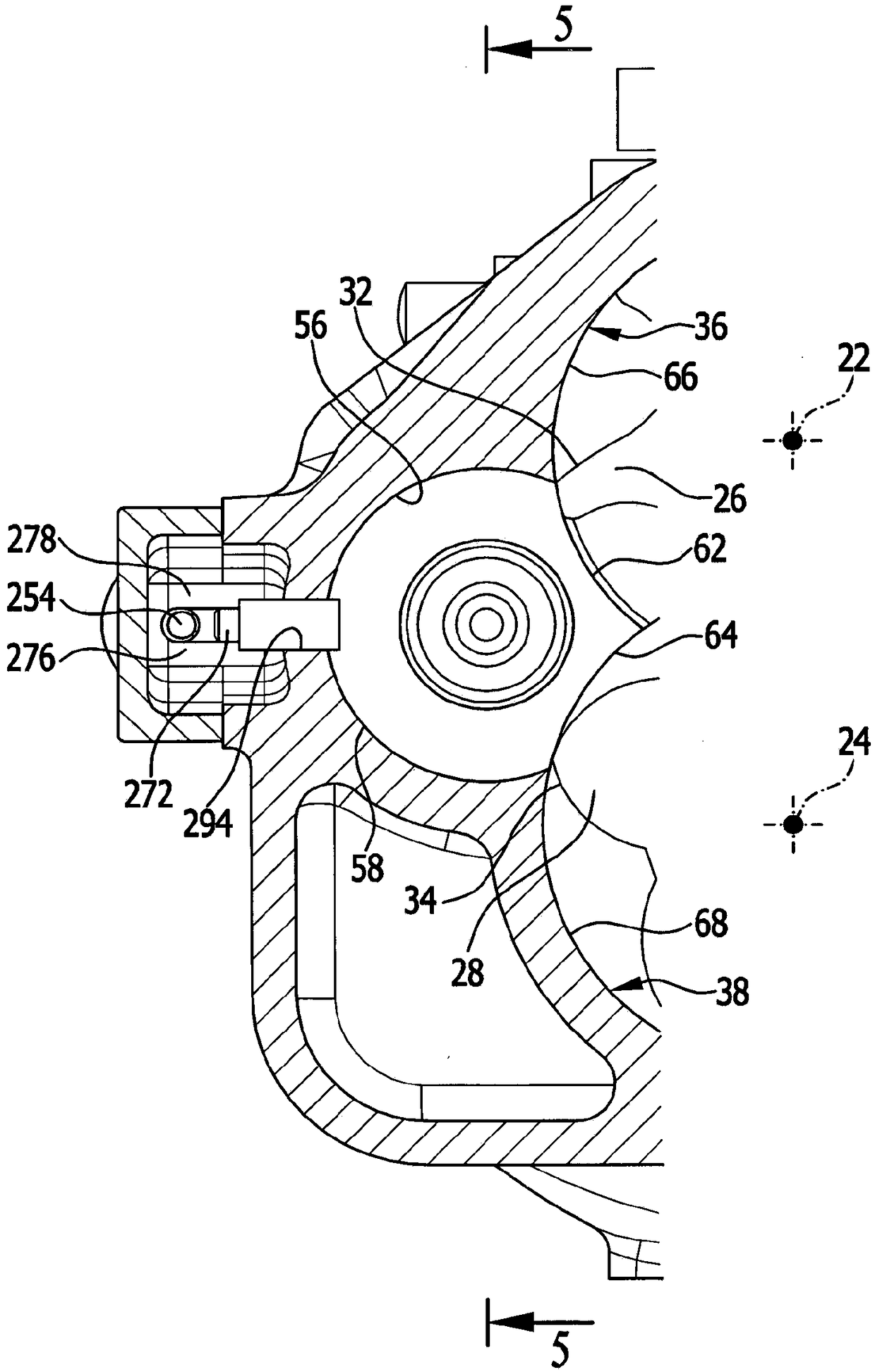

[0059] as in figure 2 with image 3 As shown in the figure, two screw movers 26, 28 that are rotatable around the screw mover axes 22, 24 respectively are arranged in the screw mover space 18 of the compressor housing 12, and the screw mover is characterized by its helical profile 32 and 34 engage with each other and cooperate with the compression wall 36 or 38 of the screw subspace 18 adjacent to the screw profile on the circumferential side in order to accommodate the pressure delivered to the low-pressure space 42 adjacent to the screw profile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com