Drive unit for a hair cutting machine

A driving device, hair clipper technology, applied in the direction of electromechanical device, magnetic circuit shape/style/structure, metal processing, etc. Optimizing material consumption, saving punching, optimizing the effect of magnetic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Corresponding parts in the following detailed figure description are respectively marked with the same symbols.

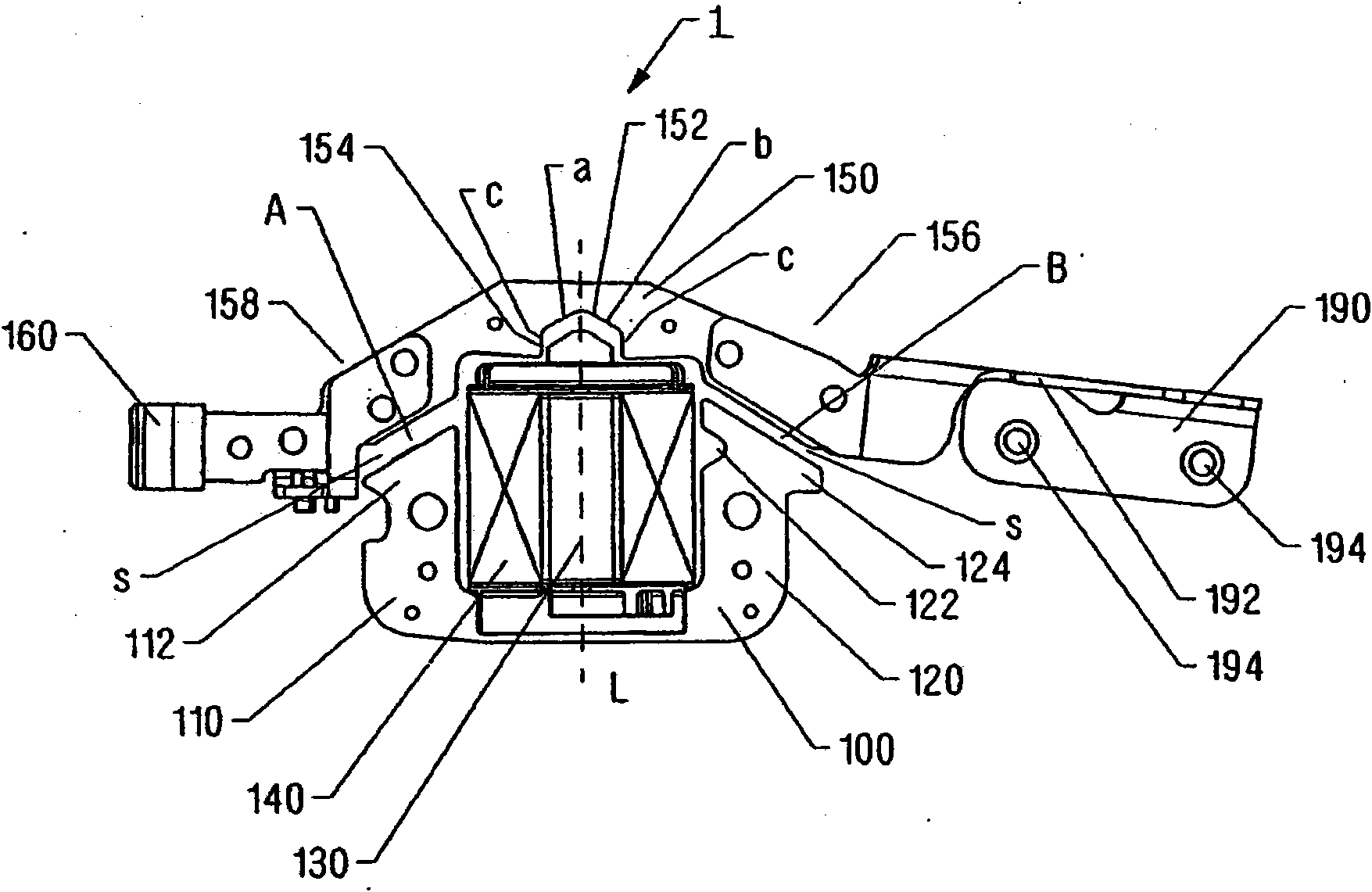

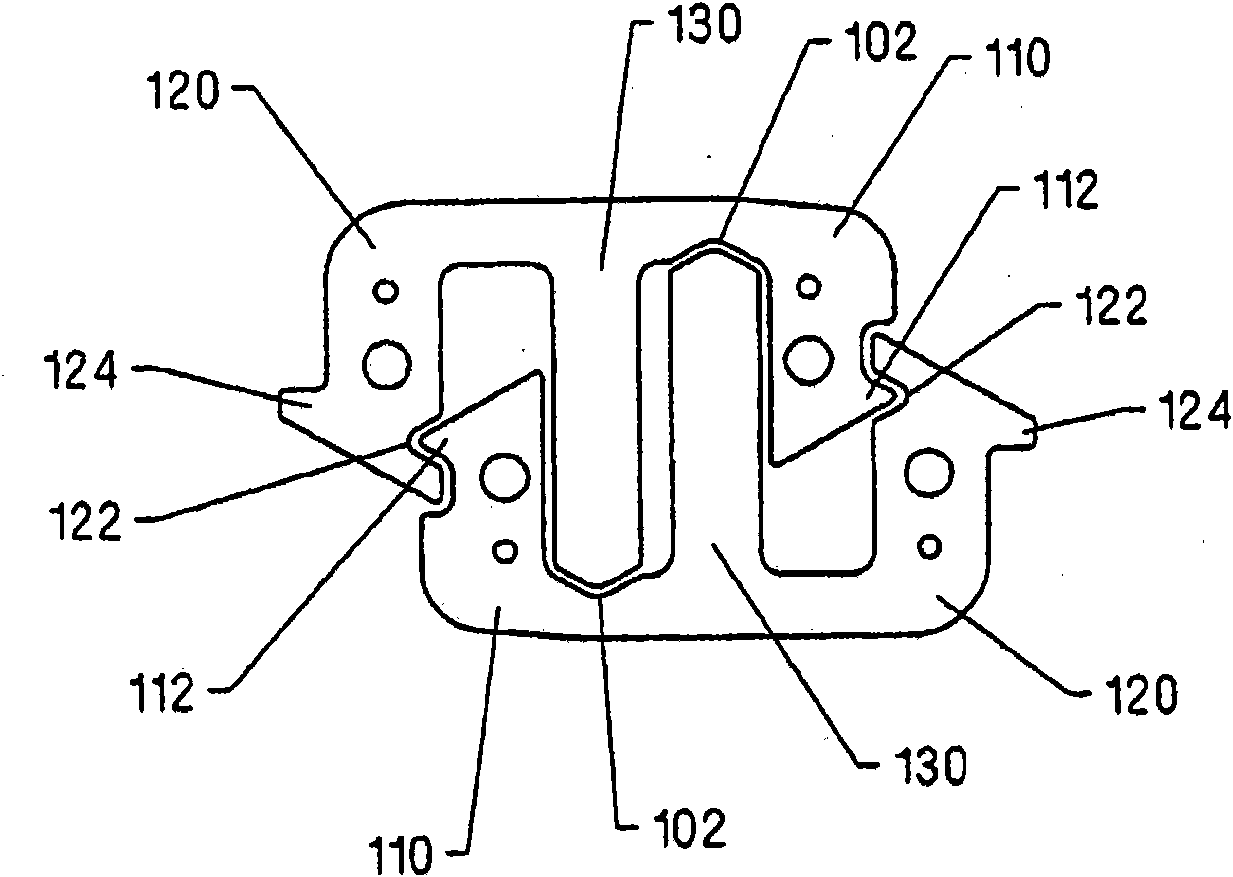

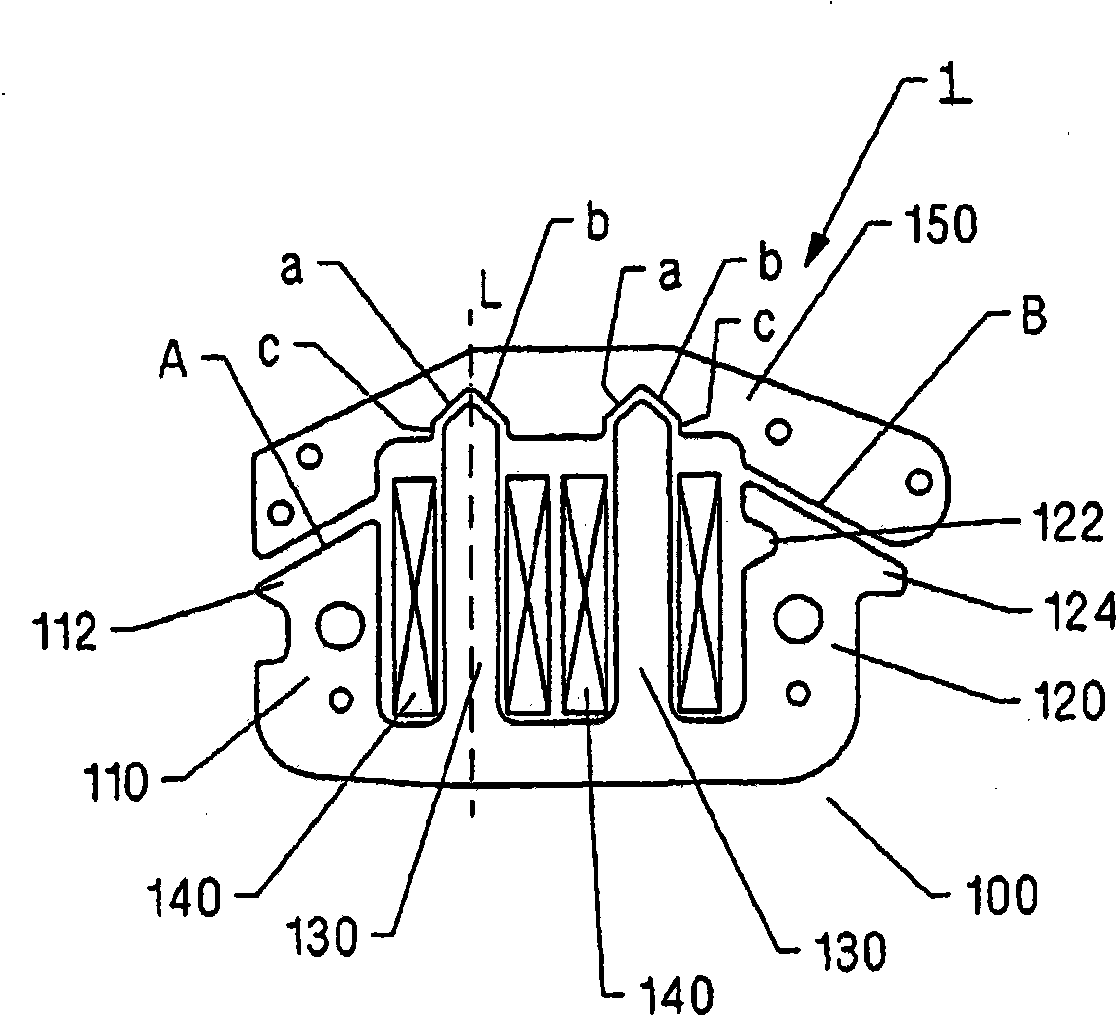

[0025] figure 1 A plan view is shown of a first exemplary embodiment of a drive device according to the invention for a hairdressing machine, which includes a drive motor 1 . The drive motor 1 is composed of a stator 100 having a field coil 140 and an armature 150 arranged corresponding to the stator 100 . The stator 100 is substantially U-shaped with a first leg 110 and a second leg 120 . An additional arm 130 is arranged between the first arm 110 and the second arm 120, on the circumference of which an excitation coil 140 is mounted. The armature 150 is arranged transversely to the ends of the arms 110 , 120 , 130 of the stator 100 , wherein a driver 160 is fixed at a first end 158 and a stand 190 is fixed at a second end 156 . The drive member 160 is configured to vibrate a blade set of the hair clipper and thereby transmit the movement of the armature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com