Use of a rolling-element bearing for bearing rotating components in vacuum devices and vacuum device

A technology of vacuum equipment and rolling elements, which can be used in parts of pumping devices for elastic fluids, rotating parts against centrifugal force, bearings, etc., and can solve the problems of expensive magnetic suspension bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

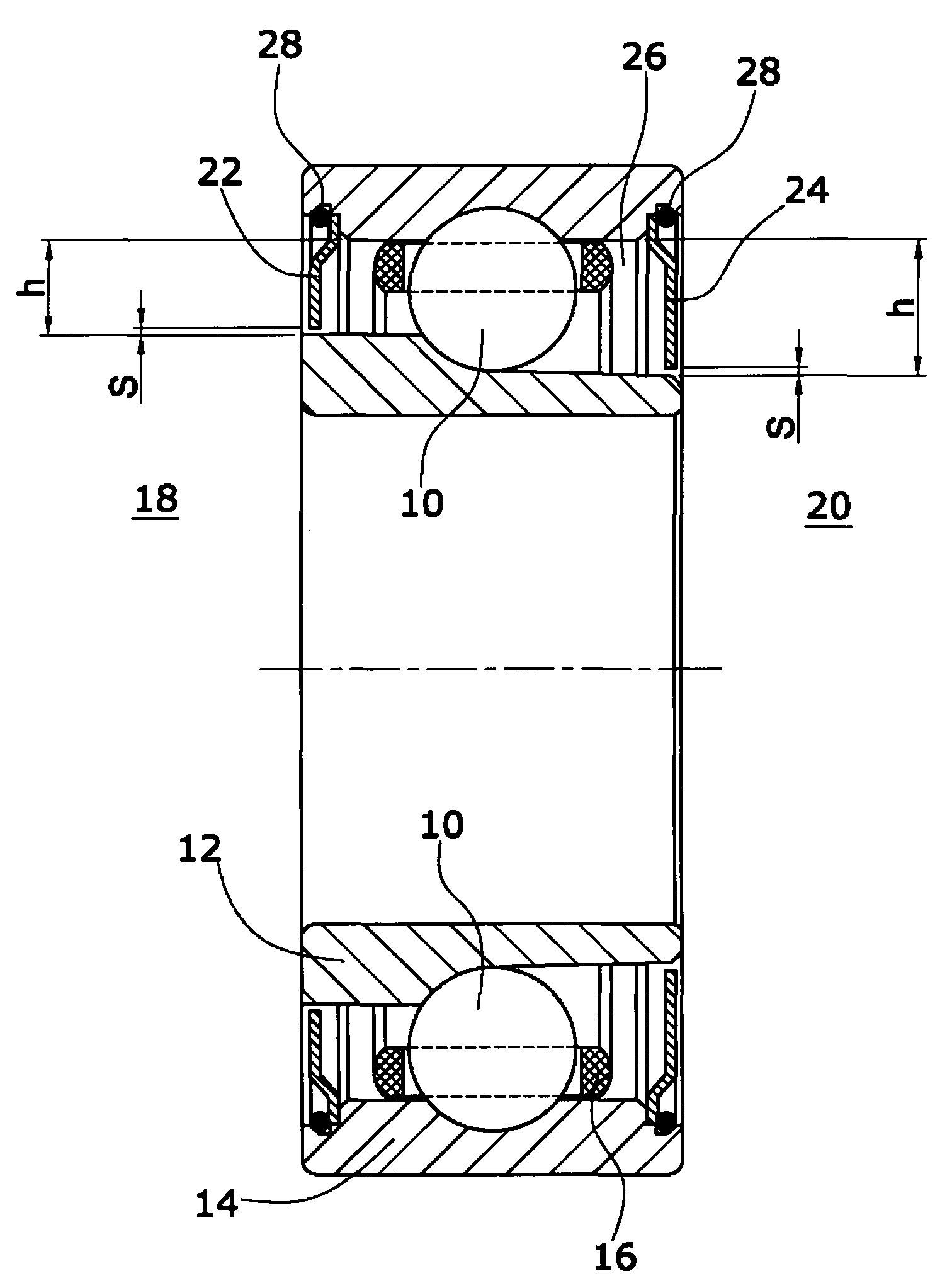

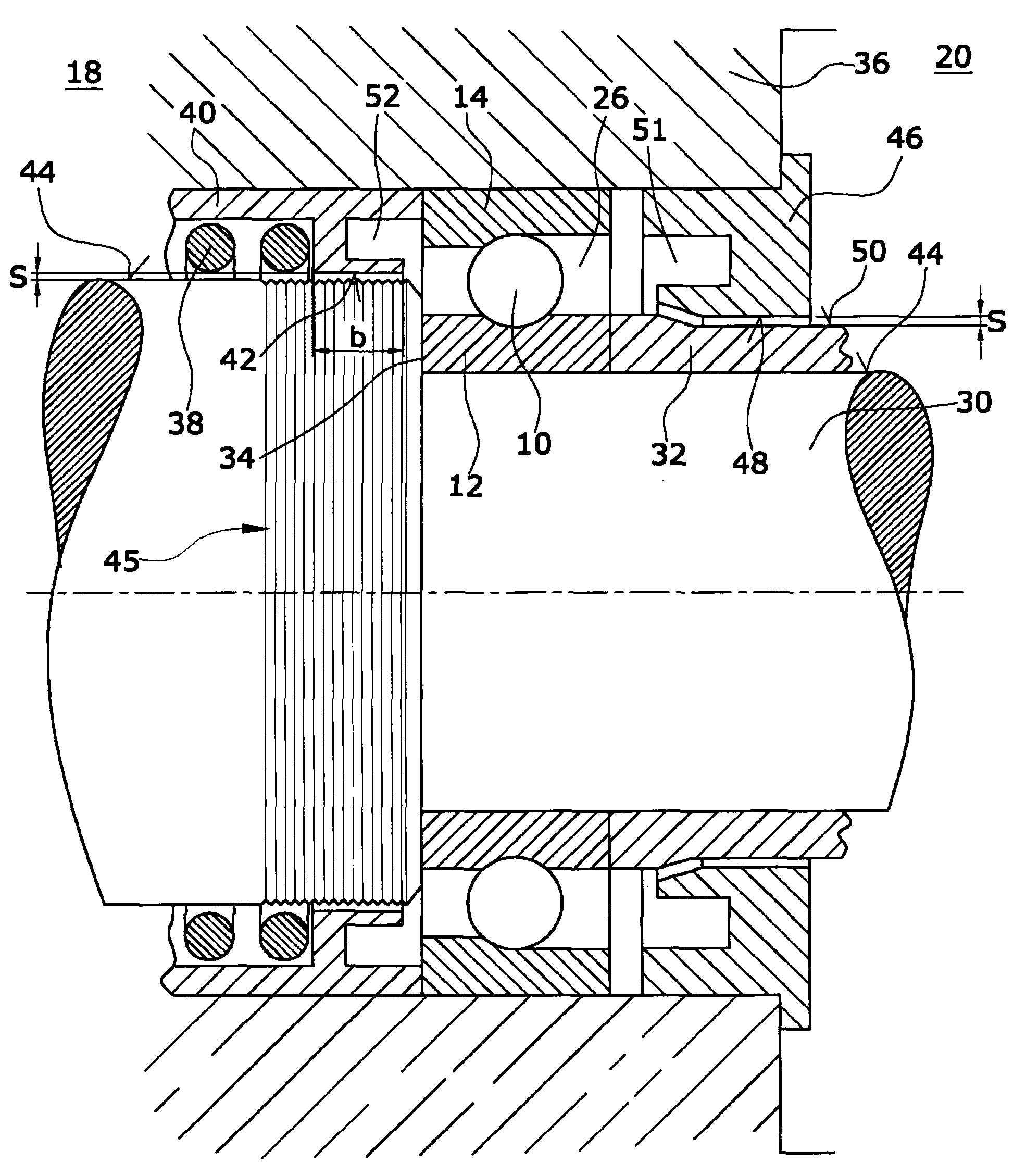

[0033] Such as figure 1 Illustrated, in a first embodiment of the rolling element bearing, rolling elements 10 in the form of balls are arranged between an inner bearing element or inner bearing race 12 and an outer bearing element or outer bearing race 14 . The rolling elements 10 are held by a cage 16 . On both sides 18 , 20 respectively delimiting the vacuum section, corresponding sealing elements 22 , 24 are provided. The two sealing elements 22, 24 delimit between them a bearing space 26, which accommodates the rolling elements 10 and is filled with a lubricating oil, such as grease. The two sealing elements 22 , 24 , which in the illustrated embodiment are crank-shaped, are fixedly connected to the outer bearing race by a retaining element, such as a safety ring 28 .

[0034]The sealing elements are designed such that they have a distance s from the inner bearing race 12 , wherein the gap width or the distance s of the sealing element 22 and the sealing element 24 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com