Device and method for cutting tobacco from a tobacco bale

A technology of equipment and tobacco, applied in the directions of tobacco, tobacco processing, cutting equipment, etc., can solve the problems of yield loss, inaccurate gap width, dirtying, etc., and achieve the effect of reducing maintenance cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The apparatus described below is particularly useful for separating tobacco from tobacco briquettes previously formed from tobacco, stems or the like and compacted. However, the invention is also applicable to the separation of other products.

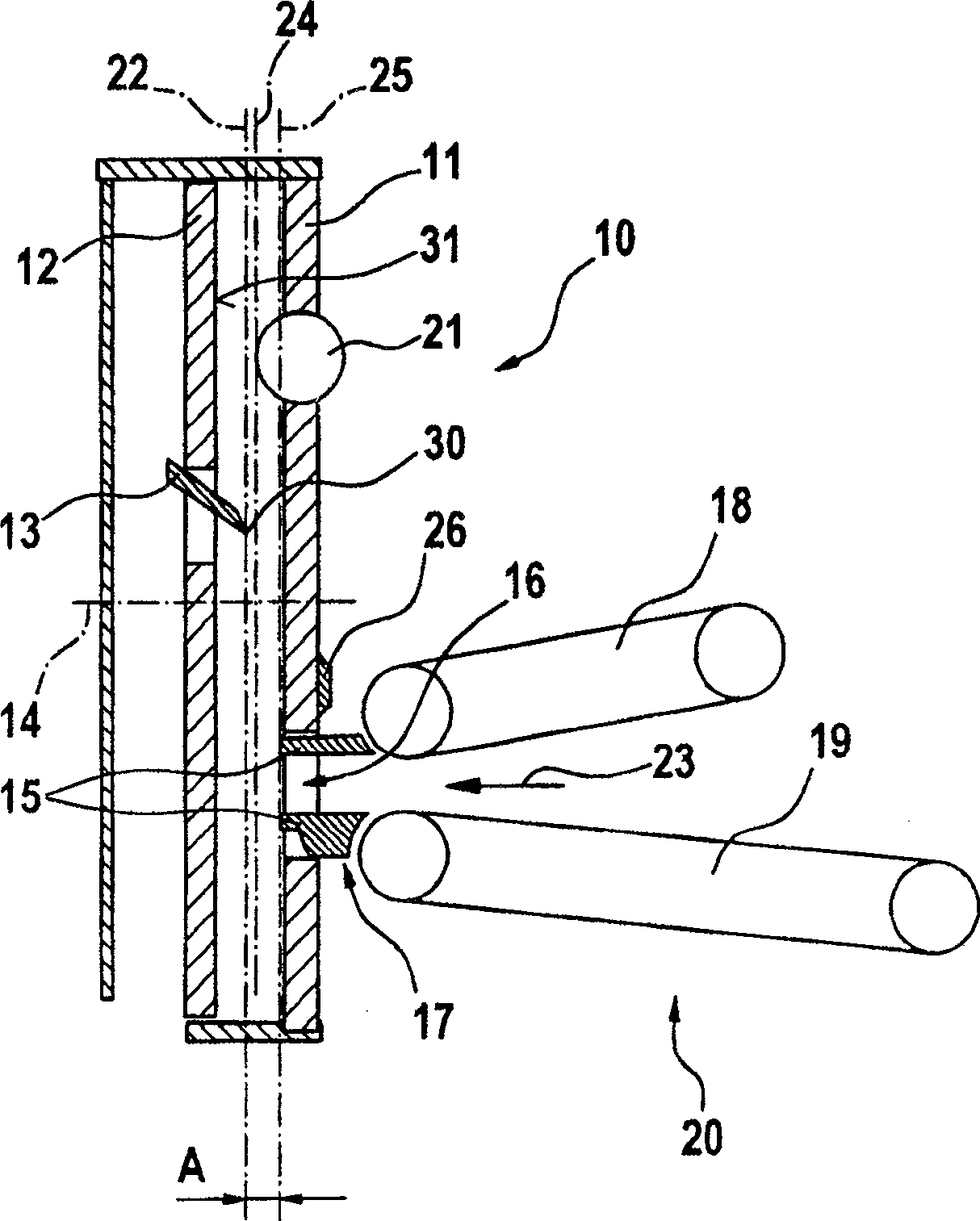

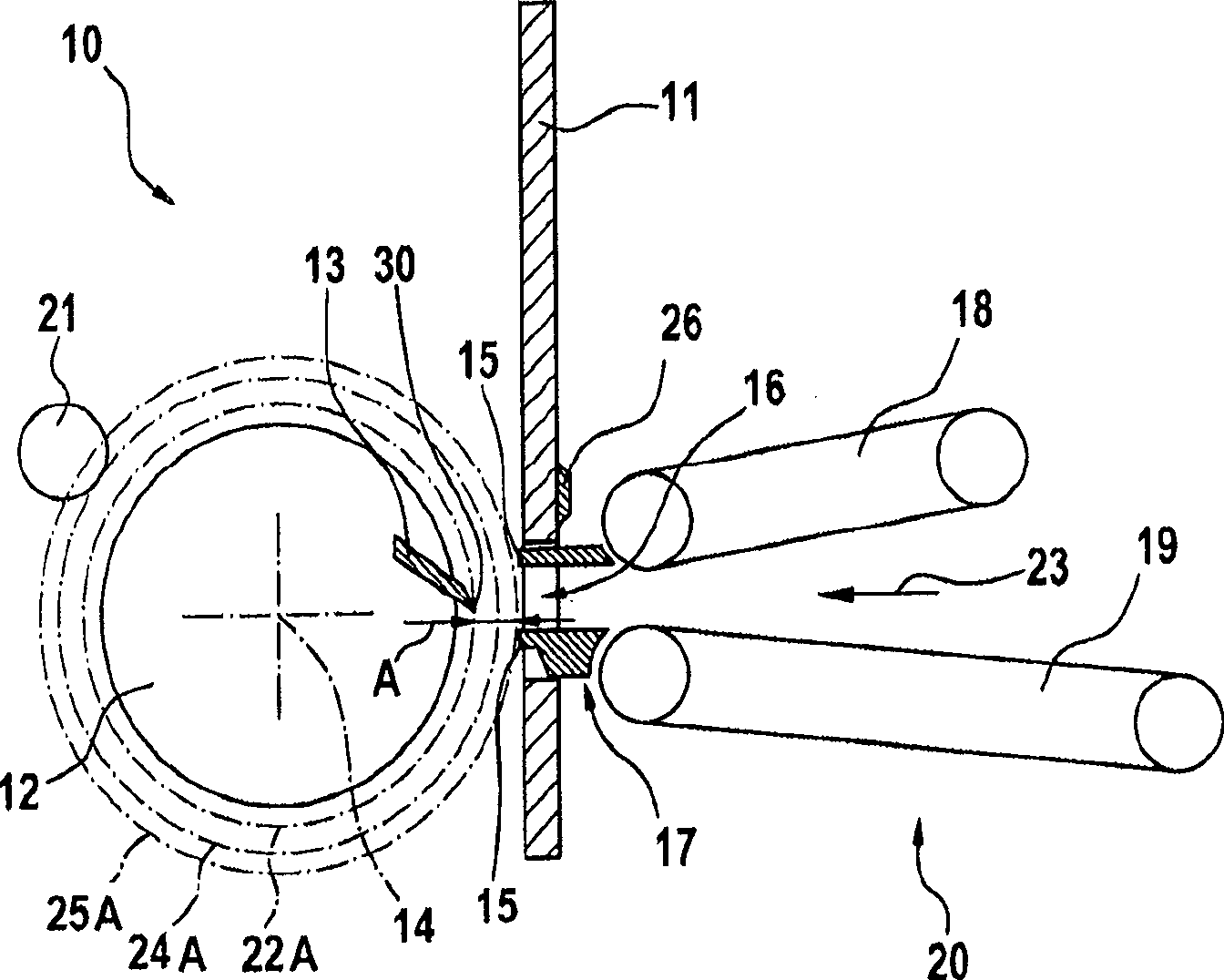

[0014] figure 1 The device 10 shown is a tobacco cutting device for separating tobacco from a tobacco block (not shown) and has a body frame 11 arranging a separating device 12 with at least one separating element 13 . exist figure 1 In the exemplary embodiment shown, the separating element 12 is configured as a cutting plate. But as an option, the separating device 12 can also be configured to cut off the drum (see figure 2 ). The separating device 12 rotates about an axis of rotation 14, and the direction of rotation can be either clockwise or anticlockwise, depending on the construction. The separating device 12 as a cutting plate in this exemplary embodiment has one or more separating elements 13 which are distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com