Conveyor dishwasher and method for operating a conveyor dishwasher

A technology of dishwasher and conveying direction, applied in the direction of dishwasher/washing machine, automatic detection under the control of dishwasher/rinsing machine, chemical instrument and method, etc., to save energy and reduce consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

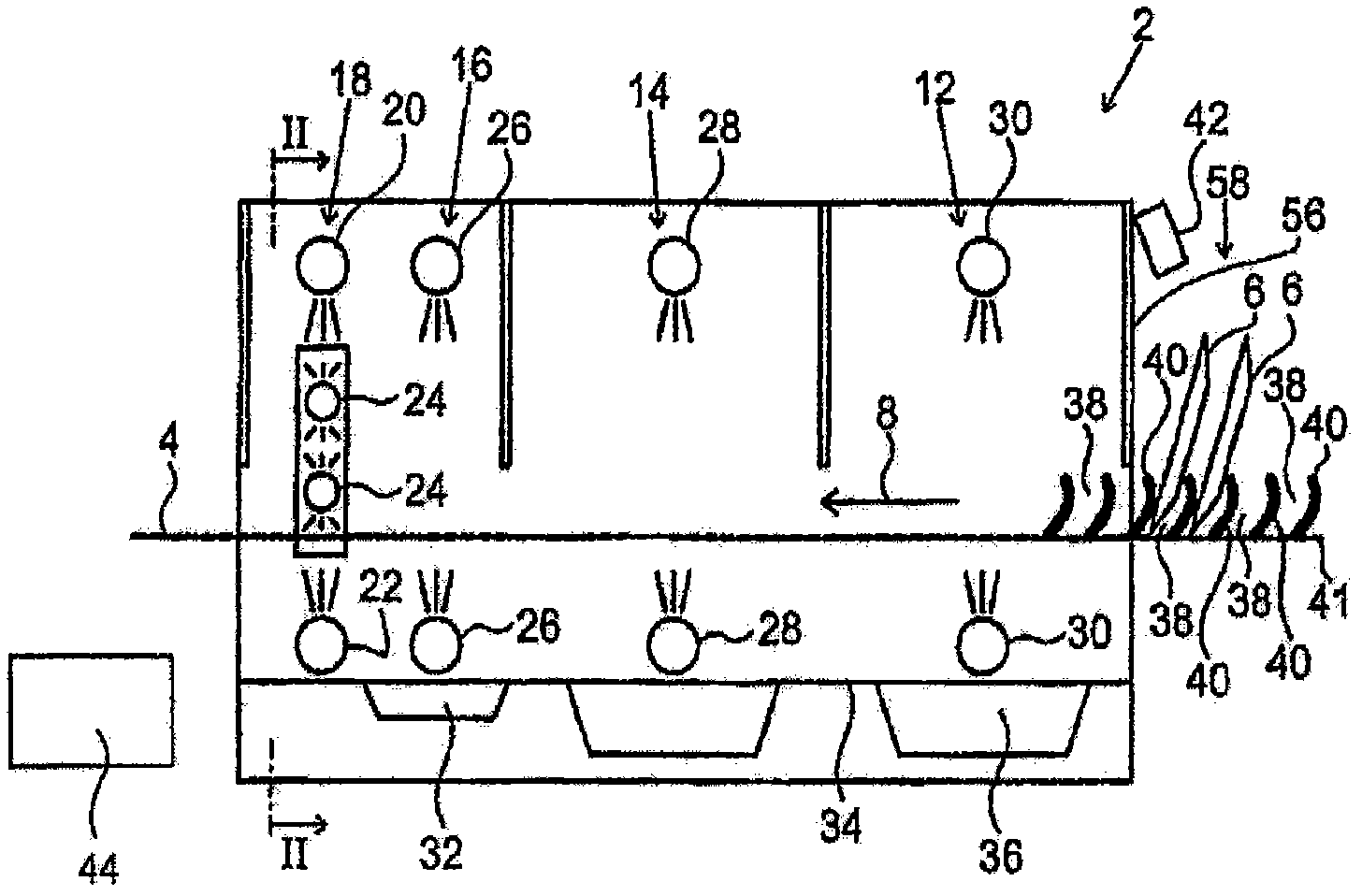

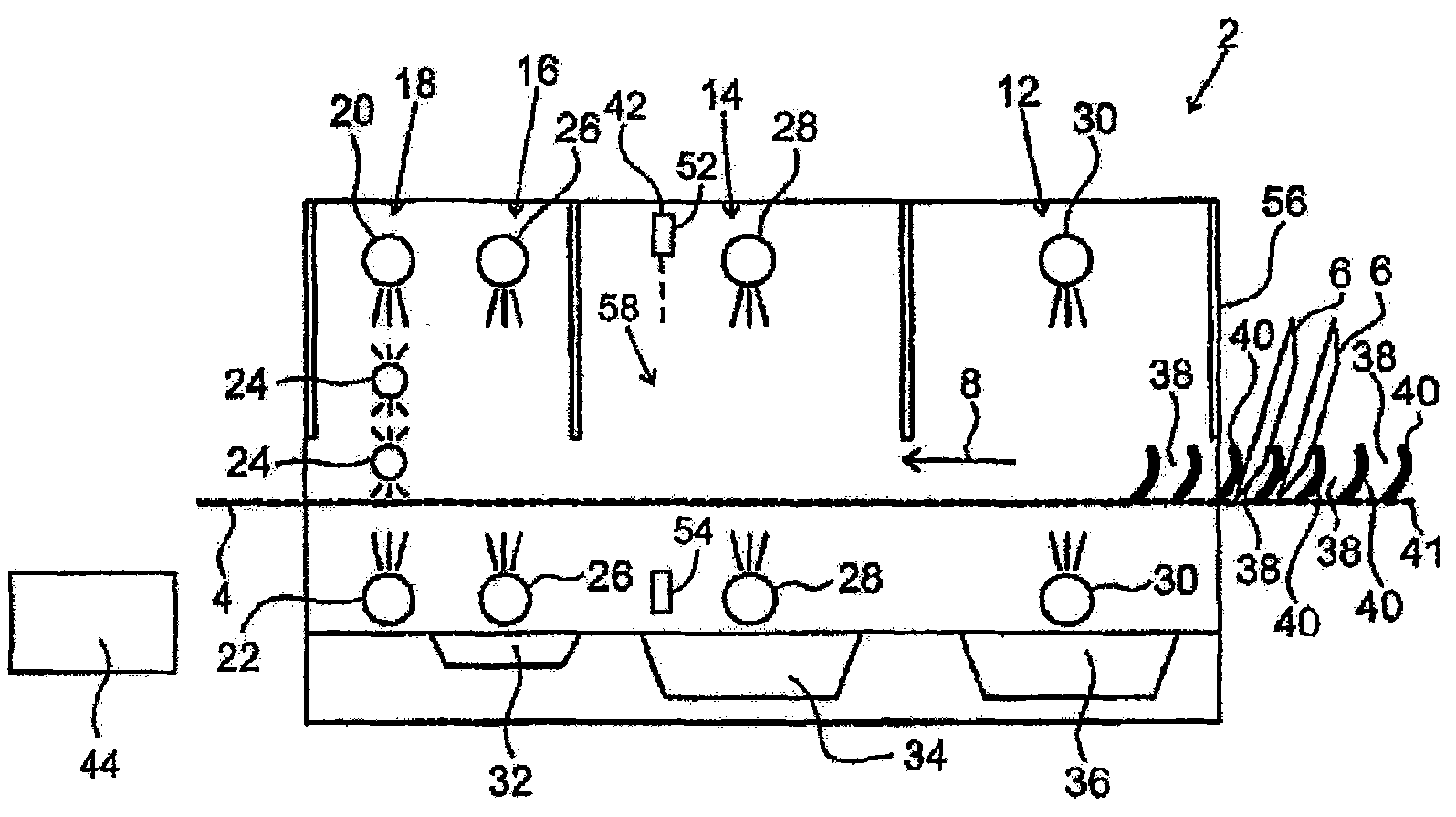

[0028] figure 1 A conveyor dishwasher 2 is shown having a conveyor device 4 that conveys dishes 6 past the housing of the conveyor dishwasher 2 in a conveying direction 8 . The conveyor dishwasher 2 has at least one washing zone, for example figure 1 Illustrated in is a prewash zone 12 and a main wash zone 14 , which is arranged downstream of the prewash zone 12 as seen in the conveying direction 8 .

[0029] The post-wash zone 16 is arranged downstream of the at least one wash zone 12 , 14 in the conveying direction 8 . At least one (for example only one is shown in the figure) final rinsing zone 18 is arranged downstream of the post-washing zone 16 in the conveying direction 8 .

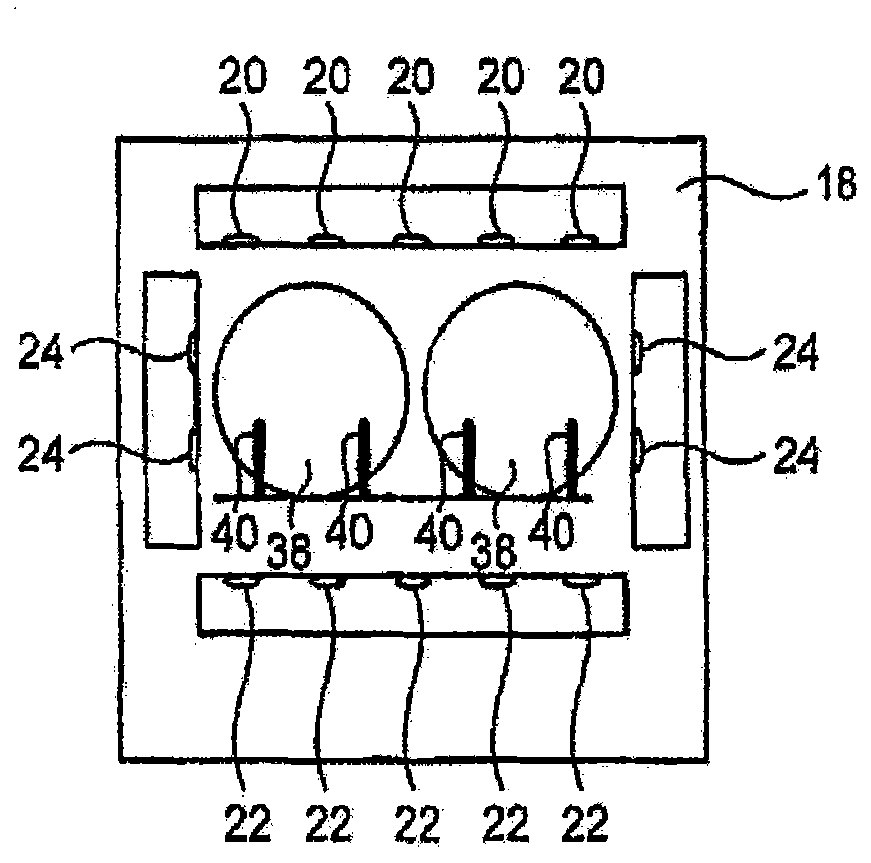

[0030]The treatment areas 12 , 14 , 16 , 18 of the conveyor dishwasher 2 have associated nozzles 20 , 22 , 24 , 26 , 28 , 30 . These nozzles 20 , 22 , 24 , 26 , 28 , 30 serve to spray liquid onto the bowls 6 when the bowls 6 are conveyed by the conveyor 4 through the respective treatment zone 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com