Device and method for portioning and packaging

一种包装方法、封闭装置的技术,应用在分份和包装装置领域,能够解决不能迅速的启动和停止、填充材料粘性限制等问题,达到节省填料成本、致动简单、减小体积流量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

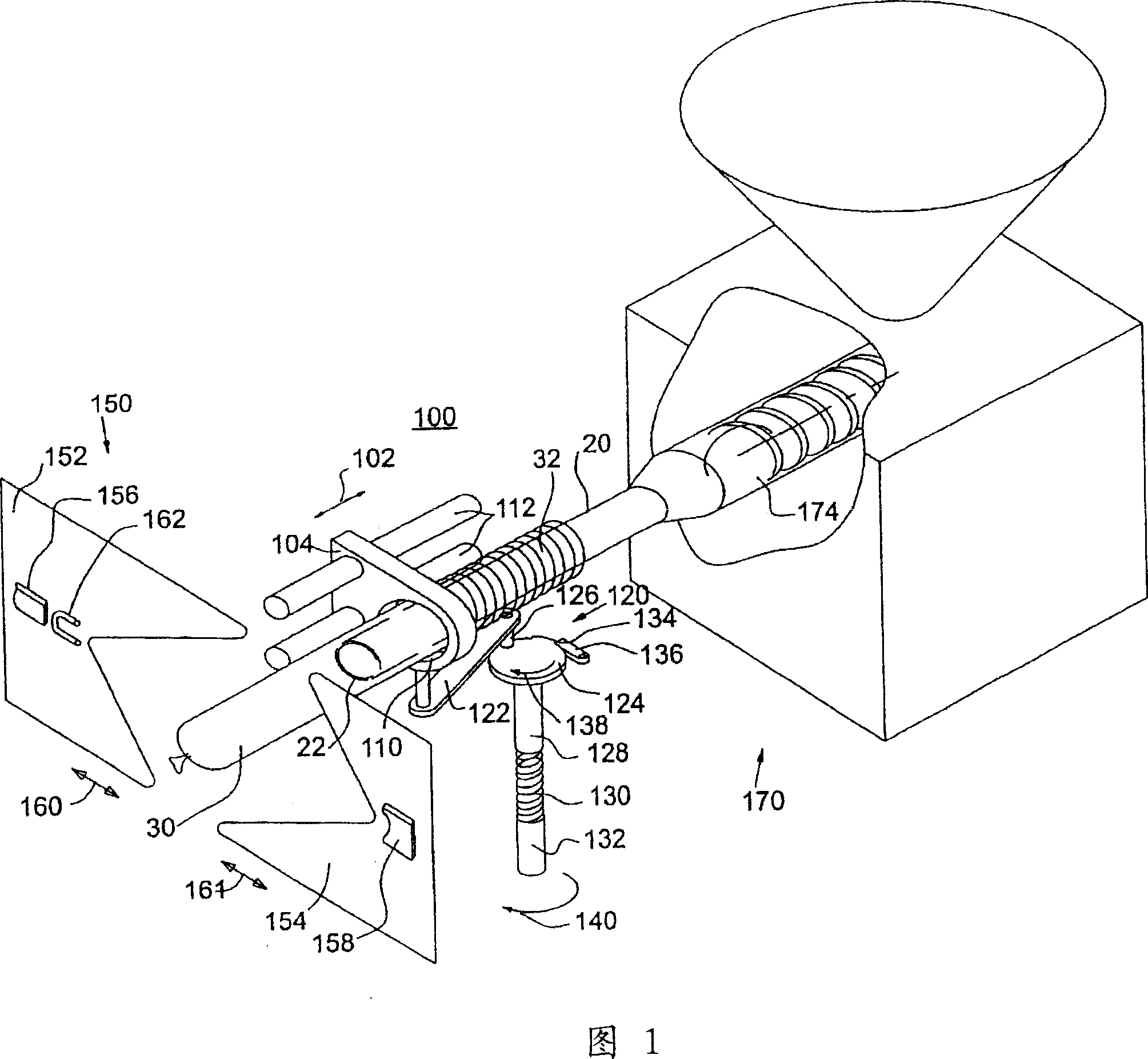

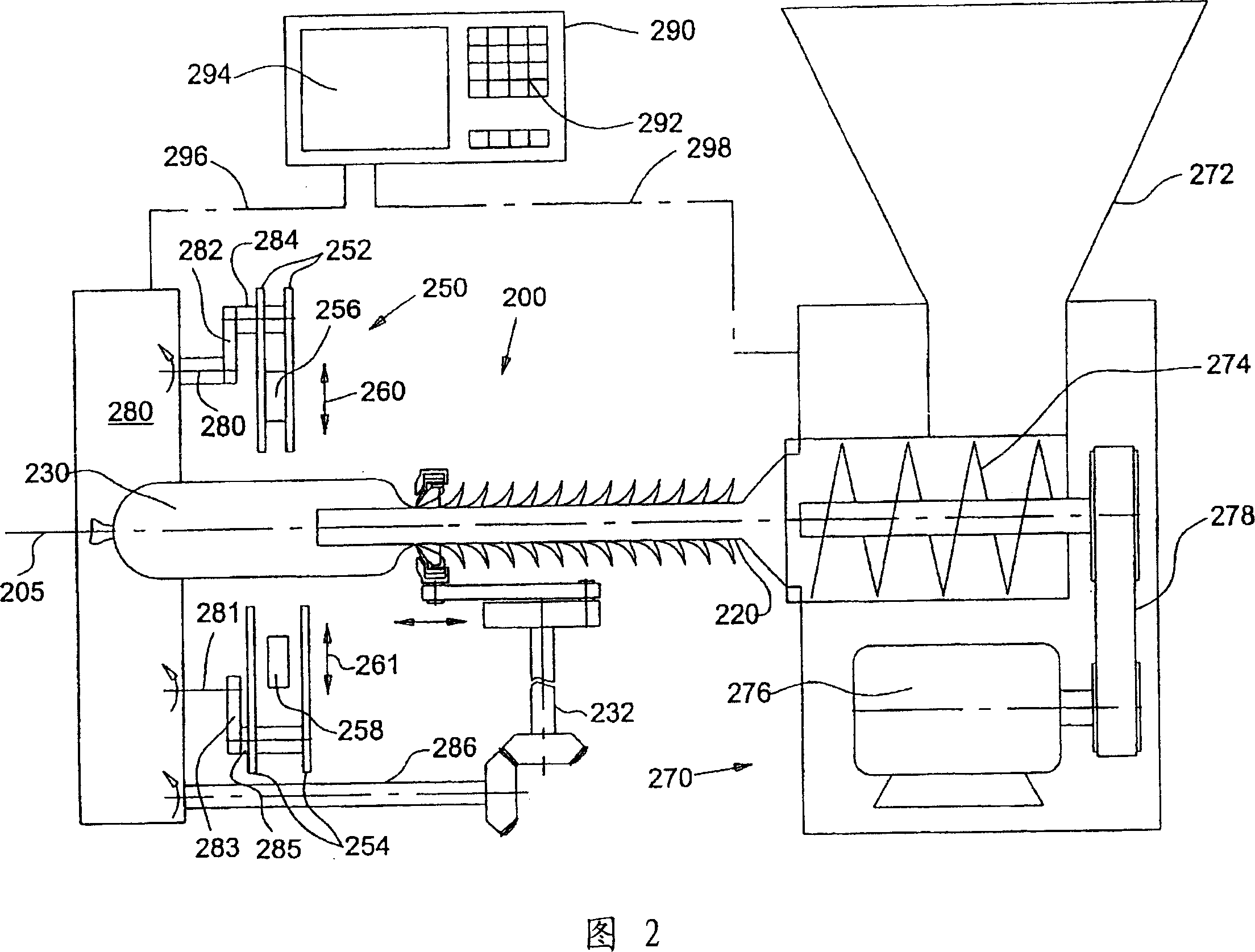

[0029] According to the present invention, the portioning and packaging device shown in Fig. 1 has a conveying device 170 for the filling material to be portioned and packaged. The filling material is fed through the inlet to a pump for generating a continuous volume flow, in the form of a funnel 172 in the illustrated embodiment. The pump includes an extruder 174 which continuously conveys the filling material in the direction of the filling tube 20 adjacent to the conveying device 170 and enters the tubular packaging casing 30 with one end closed through the mouth opening 22 on the filling tube 20. In this case, the packaging case 30 is pulled down from the corrugated "caterpillar skin"-shaped supply member 32.

[0030] Therefore, this situation will not happen uncontrollably. The holding device 100 arranged on the filling tube 20, more precisely, the system surrounding the filling tube 20 by a circle and reciprocating in parallel in the direction indicated by the double-headed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com