Exhaust emission control device for a water vehicle and method for operating an exhaust emission control device

A technology of exhaust emission and control device, which is applied in the direction of exhaust device, muffler device, exhaust gas treatment, etc., can solve problems such as difficulty, large installation space for ships, large cost, etc., and achieves reduction of production cost, investment cost, installation space, etc. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

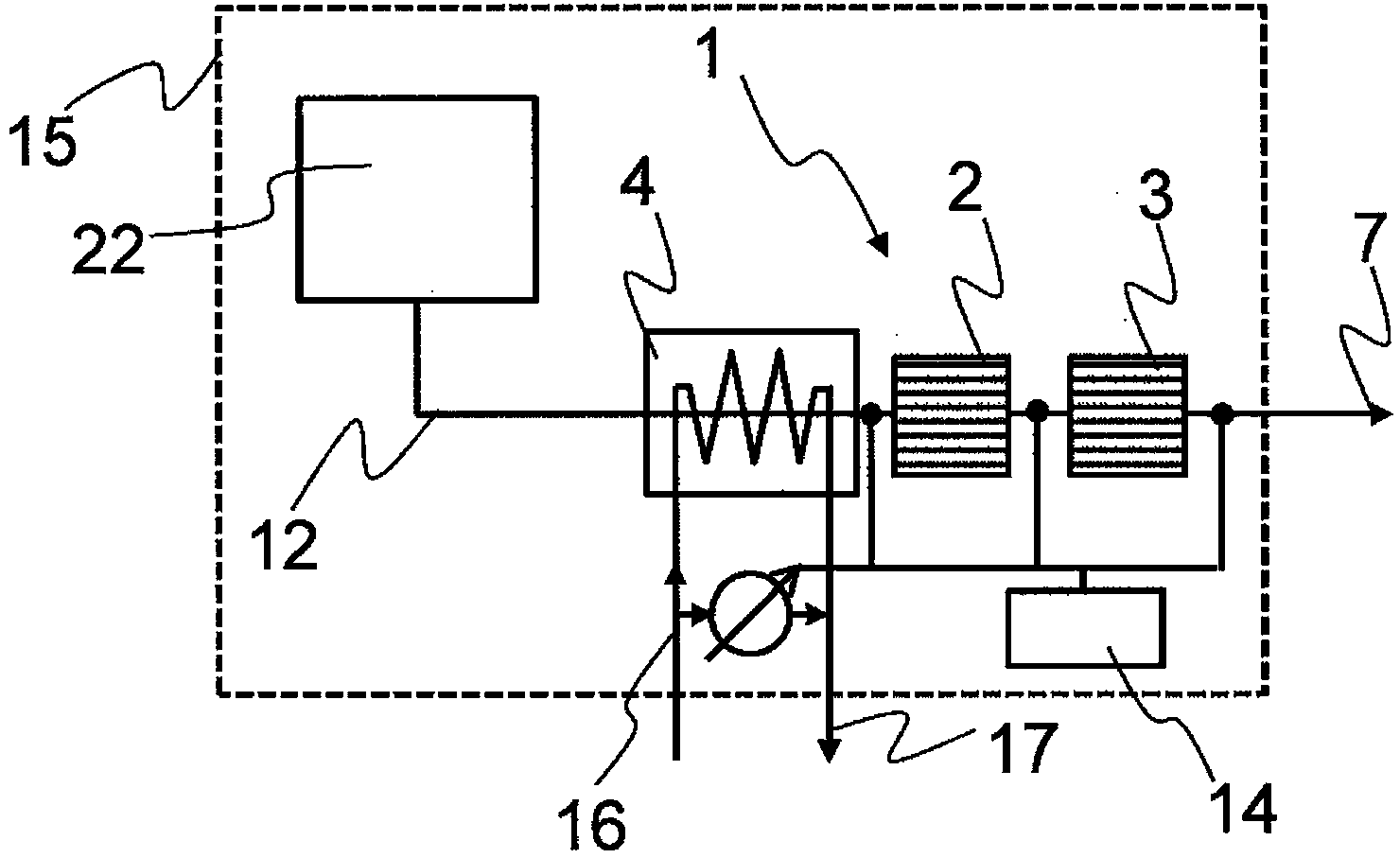

[0039] figure 1 A vessel 15 is schematically shown with a drive 22 and a discharge pipe 12 connected to the drive 22 . Exhaust pipe 12 conveys exhaust gas 7 to exhaust emission control device 1 which has heat exchanger 4 and downstream of the heat exchanger particle filter 2 and SCR catalytic converter 3 . The heat exchanger 4 comprises a cooling circuit which operates with sea water 16 as cooling medium 17 . In particular, the use of seawater heat exchangers is advantageous, since said heat exchangers are implemented as "open" circuits, in which fresh (cold) seawater is constantly supplied and heated seawater can be discharged back into seawater (via discharge line). In addition, this seawater can also be used to cool other parts of the ship, such as internal combustion engines. The exhaust emission control device 1 also includes a controller 14 which is connected to the corresponding sensor and the heat exchanger 4 in the emission line.

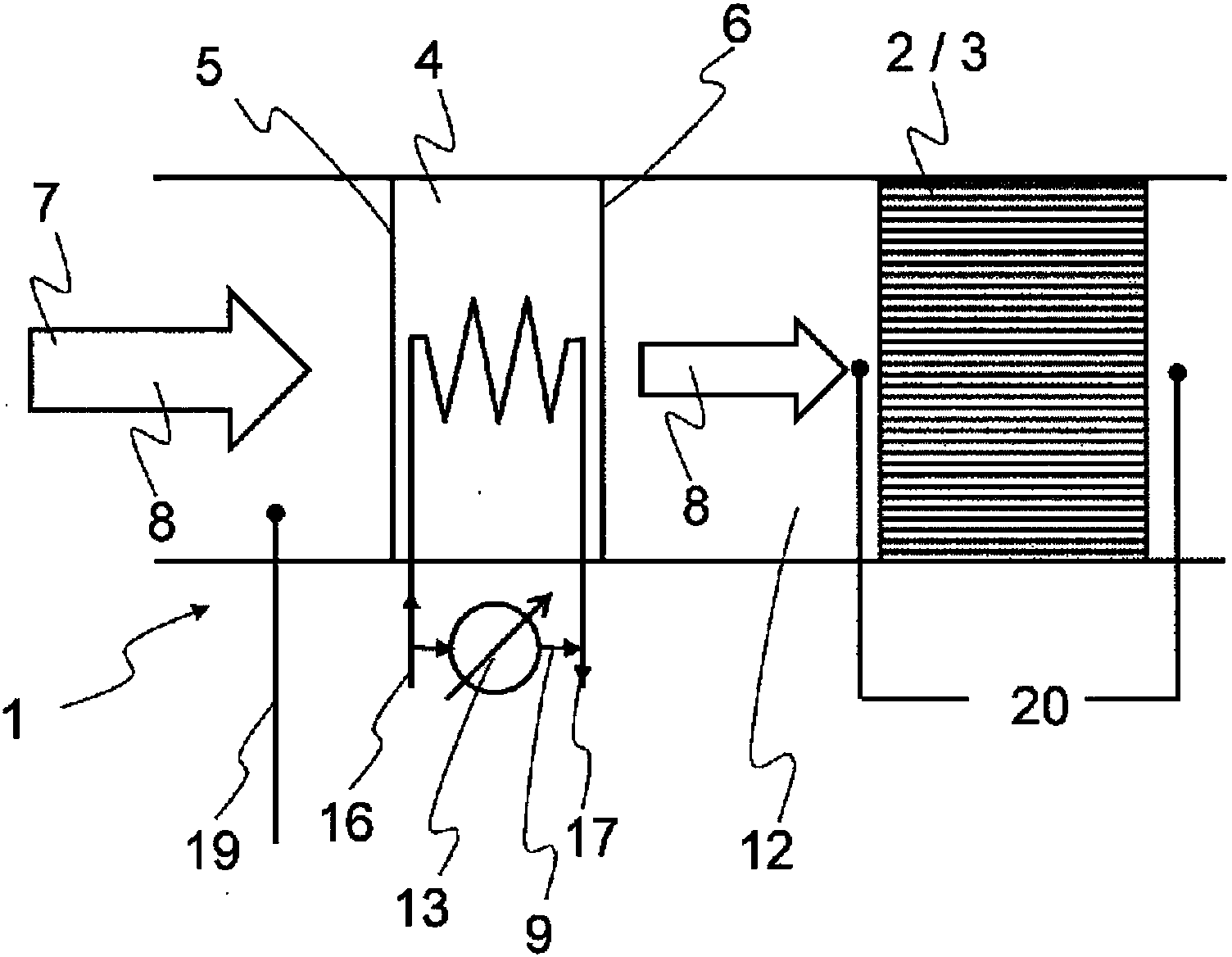

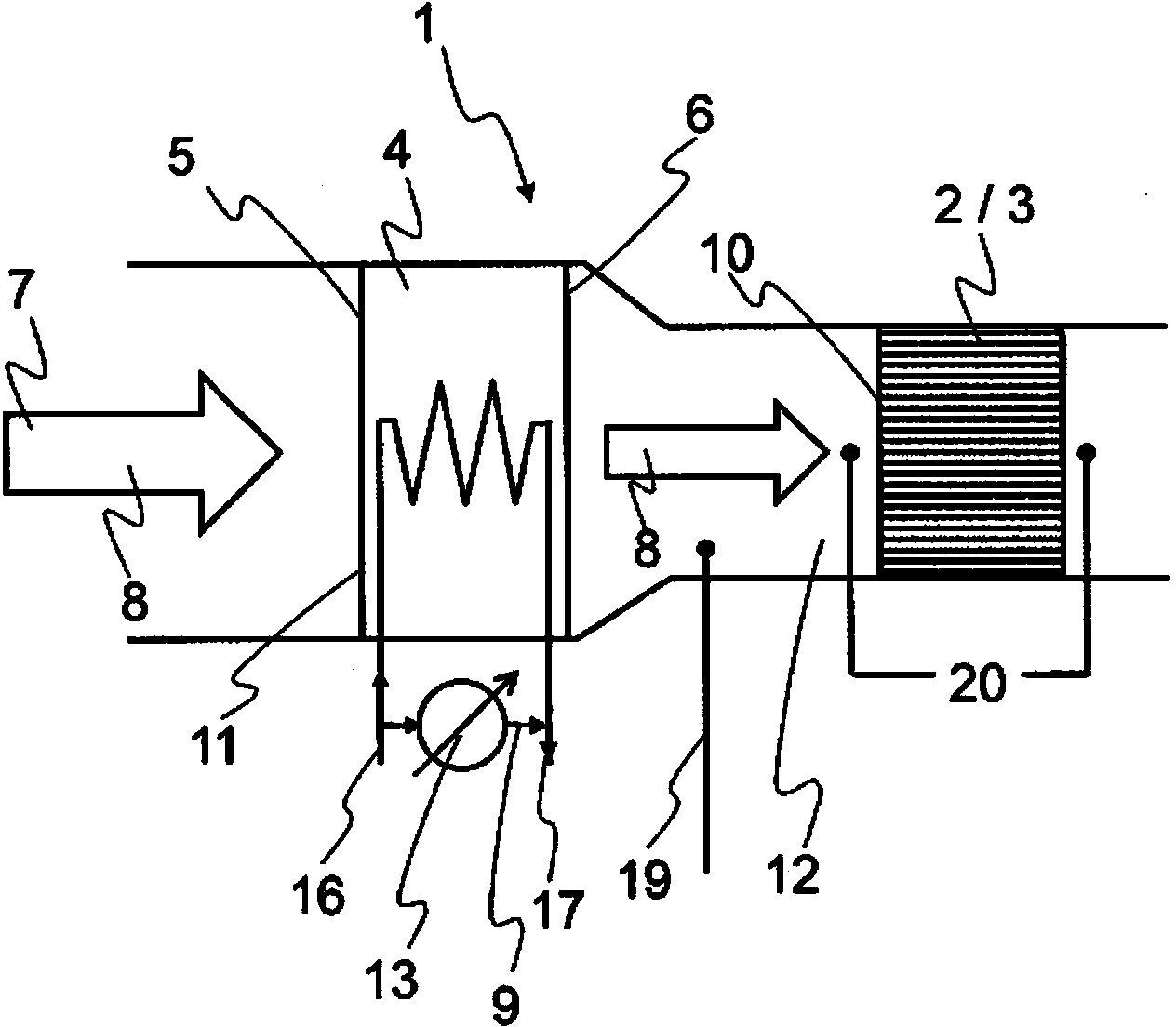

[0040] figure 2 A first embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com