Controllable oil separation device

An oil separation and equipment technology, applied in the field of controllable oil separation equipment, can solve the problem of not being able to improve separation performance, and achieve the effects of small overall size, improved separation performance, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

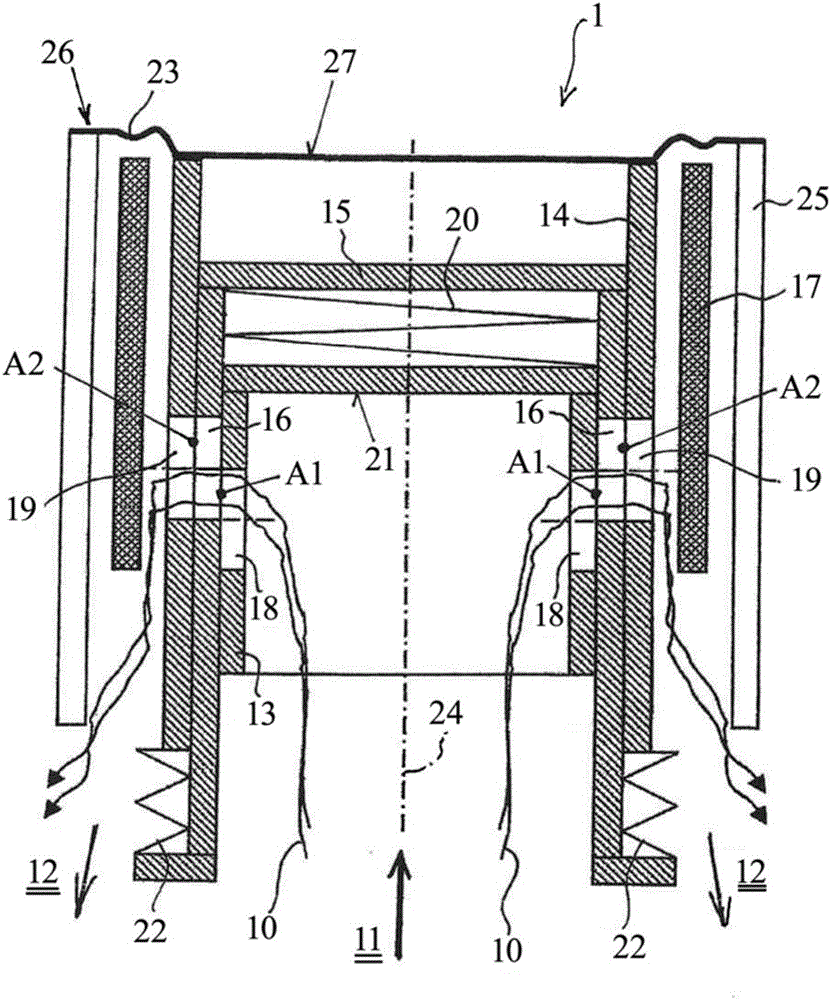

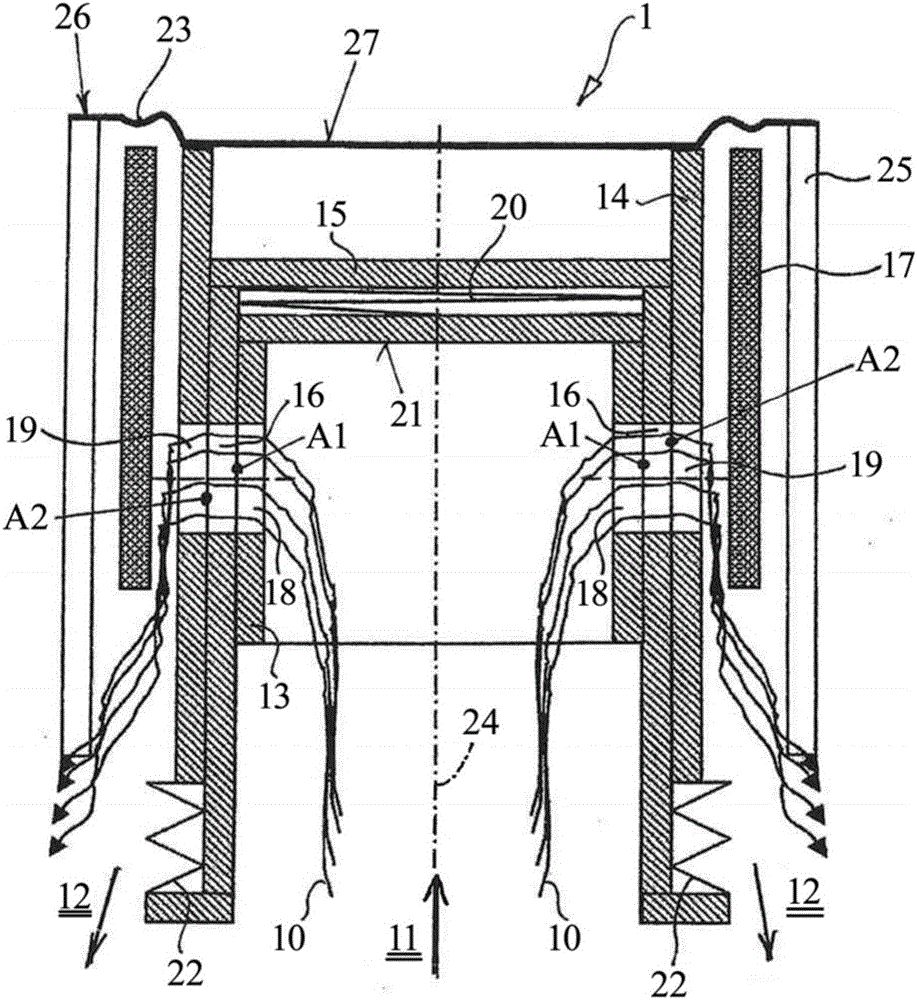

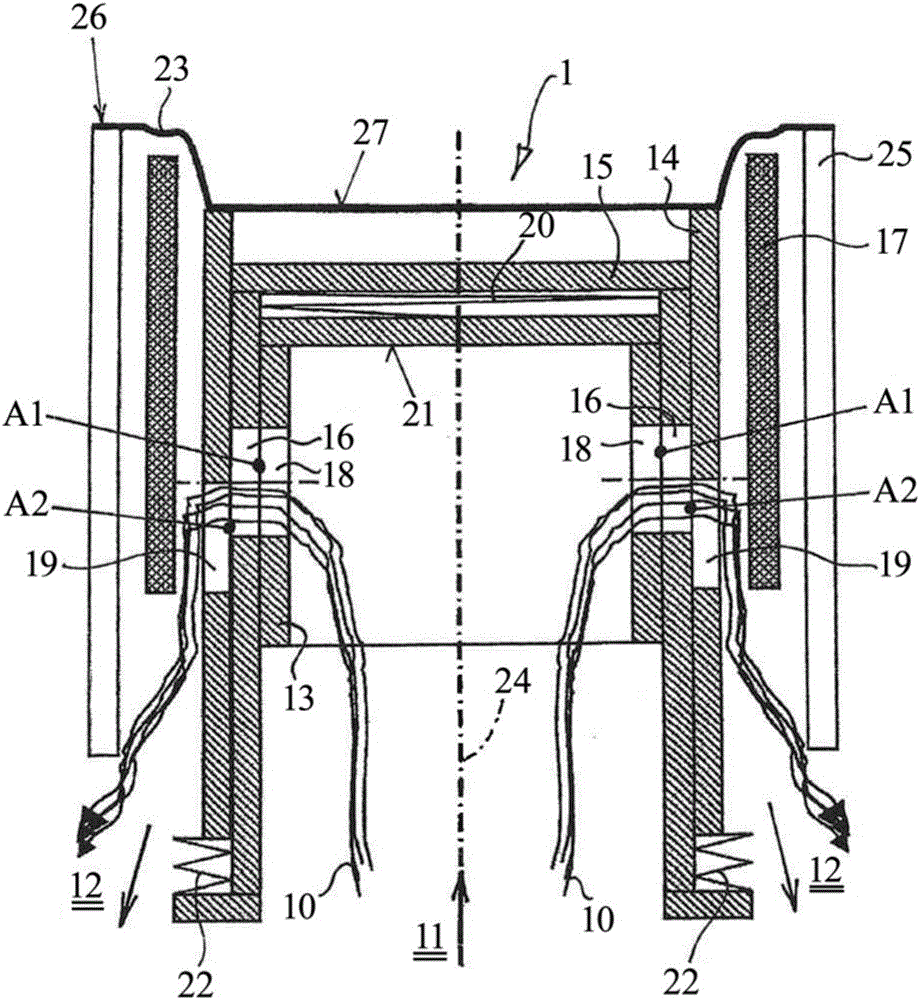

[0028] exist Figure 1 to Figure 4c In , features with the same technical function and effect are denoted by the same reference numerals.

[0029] Figure 1 to Figure 4c Each of these shows an embodiment of the oil separation device 1 in various operating states corresponding to various operating moments of the internal combustion engine. Therefore firstly the description is independent of the operating state according to Figure 1 to Figure 4c The configuration of the oil separation device 1 illustrated in .

[0030] The oil separation device 1 serves to separate oil from an air flow 10 which ventilates the crankcase of an internal combustion engine. For this purpose, the oil separation device 1 has an inflow side 11 which can be fluidically connected to the crankcase of the internal combustion engine. The oil separation device 1 also has an outflow side 12 which can be connected to the intake duct of the internal combustion engine.

[0031] The oil separation device 1 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com