External heat radiation regenerative oil shale dry distillation furnace

A dry distillation furnace and regenerative technology, which is applied in the field of oil shale dry distillation and oil refining, can solve the problems of difficult enlargement of furnace scale, difficult maintenance, waste of resources and environment, etc., and achieve the effects of improving thermal efficiency, improving airtightness and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

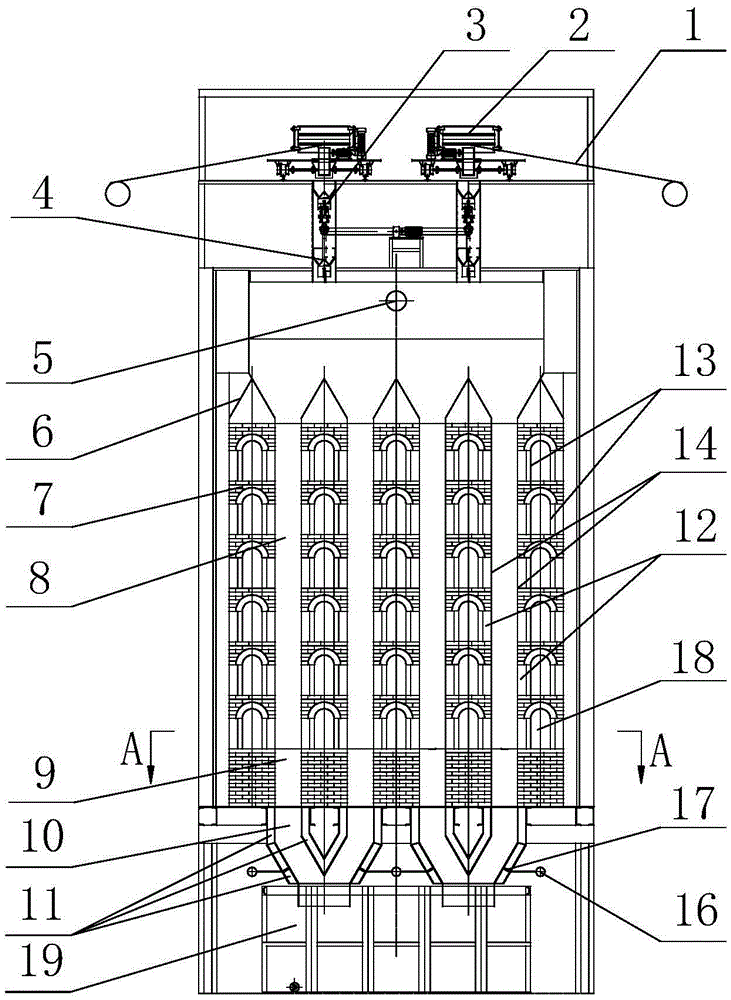

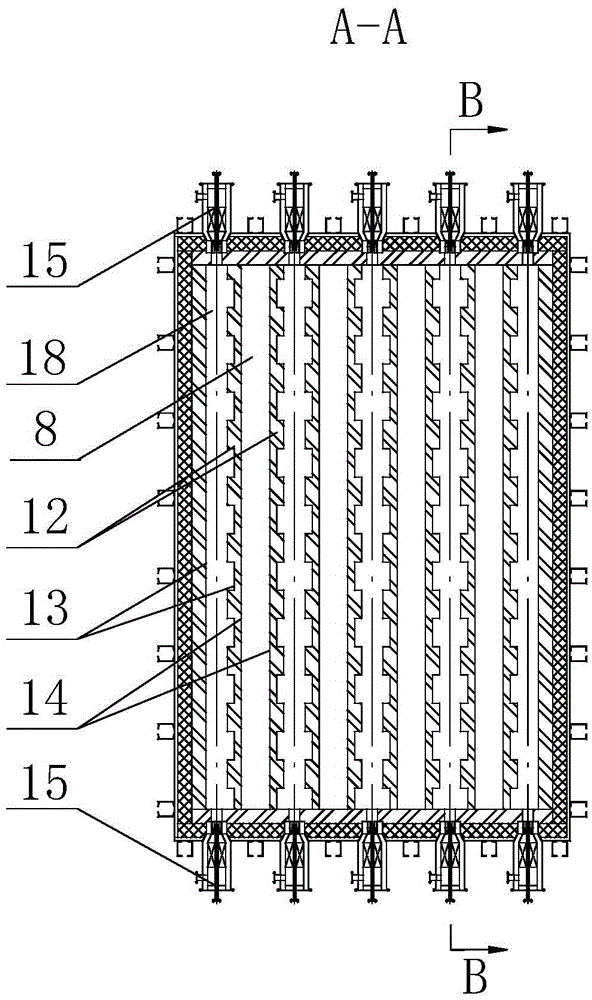

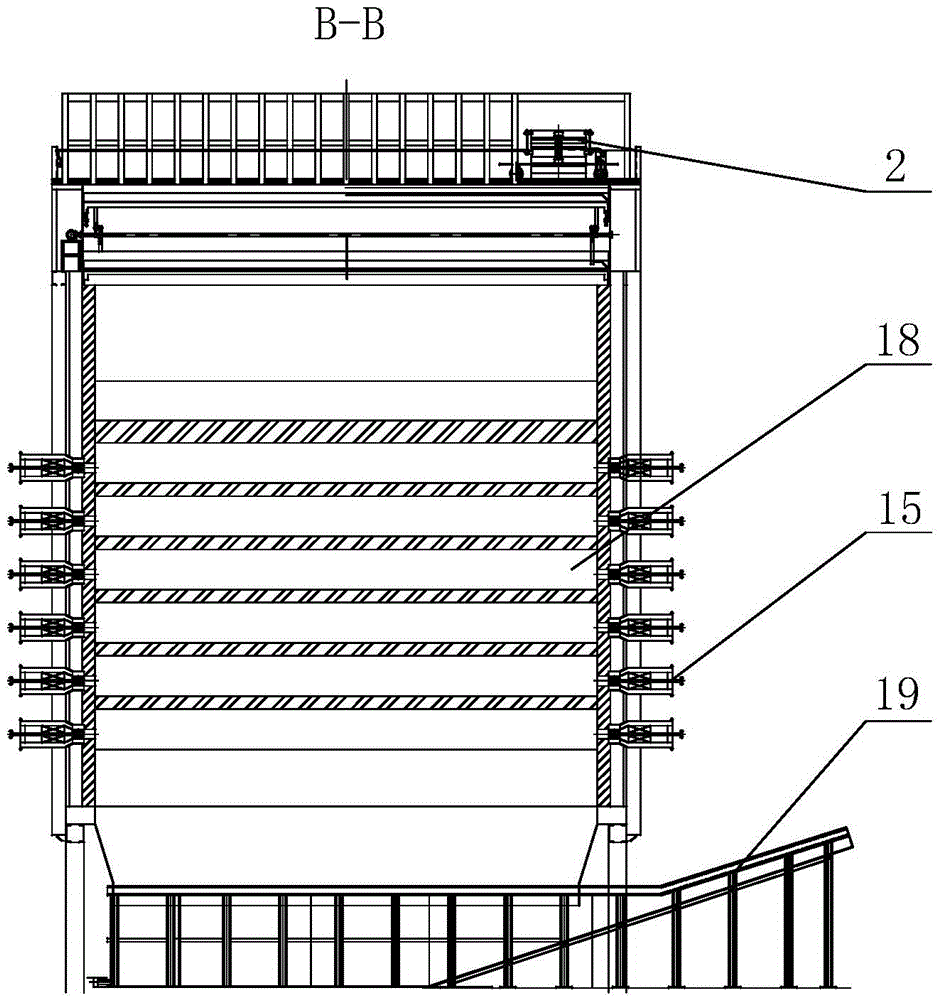

[0040] Embodiment 1: The present invention provides a kind of external heat radiation regenerative oil shale dry distillation furnace, its structure is as follows figure 1 , 2 As shown in , 3, the retort furnace includes a furnace body of the retort furnace, a feeding system on the upper part of the furnace body and a slagging device at the bottom of the furnace body. , Feeding bell 3, blanking bell 4 and triangular baffle 6. The oil shale is lifted to the top of the retort furnace through the feeding device 1 and added to the distribution trolley 2. The distribution trolley 2 moves along the track of the feeding trolley set on the furnace top. The vibrating material distributing mechanism spreads the oil shale evenly in the charging bell 3 installed on the roof of the retort furnace, and the charging bell 3 and the lower charging bell 4 arranged below it form a double feeding bell mechanism to complete the uniform distribution of oil shale to the retort furnace. fabric. Ea...

Embodiment 2

[0049] Embodiment 2: A kind of external heat radiation heat storage type oil shale carbonization furnace provided by the present invention, its structure is basically the same as that of Embodiment 1, the difference is that in order to expand the production capacity of a single furnace, the combustion chamber 7 is designed into 20 rows, each row The combustion chamber is designed with 12 layers of combustion channels 18, and correspondingly there are 19 rows of retort chambers 8, through which gas and air are burned in the combustion channels 18, and the battlemented structure wall 13 of the heat conduction wall 12 is heated to 1000°C, and the heat is transferred to The flat and straight structure wall 14, the temperature of the flat and straight structure wall can reach 600°C, and the rest are the same as in embodiment 1. The daily processing capacity of the dry distillation furnace of the invention can reach more than 500t, and the oil yield is more than 90%.

[0050] The dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com