Hydrostatic drive system

A hydrostatic drive and hydraulic technology, applied in the field of hydrostatic drive system, can solve the problems of complex structure, structure consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

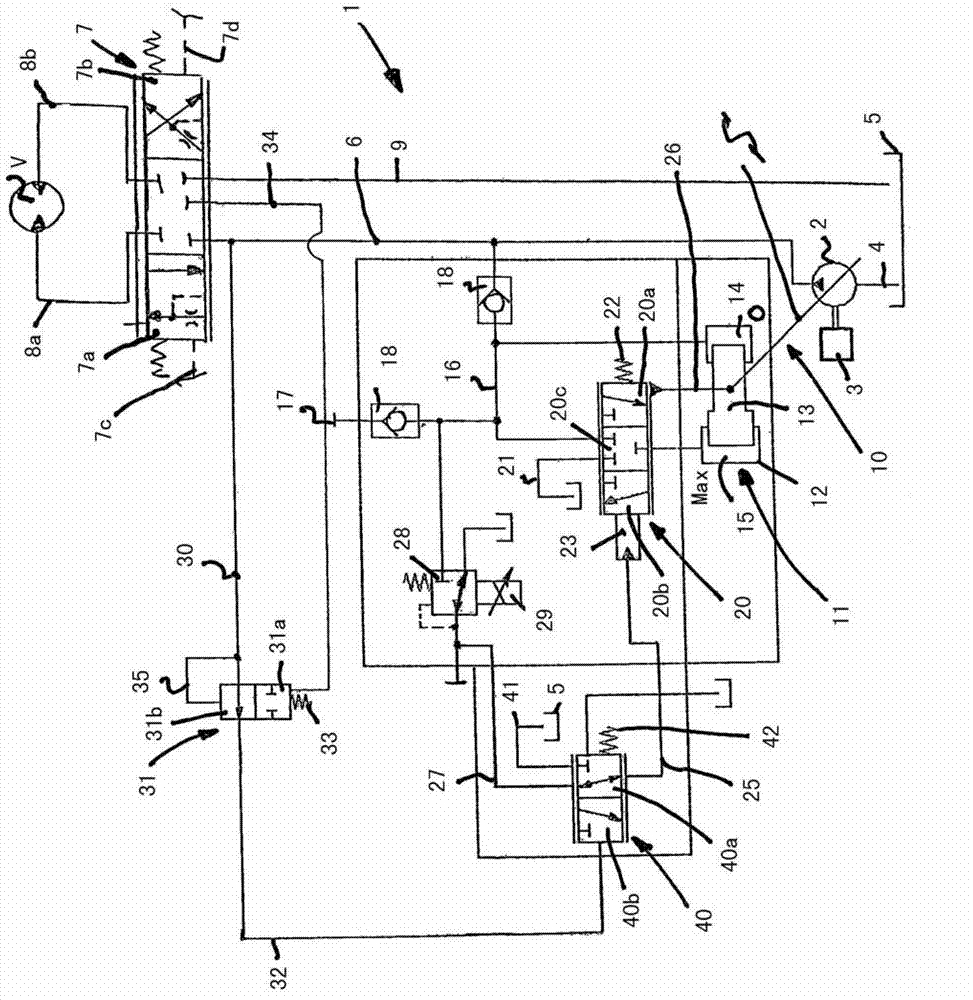

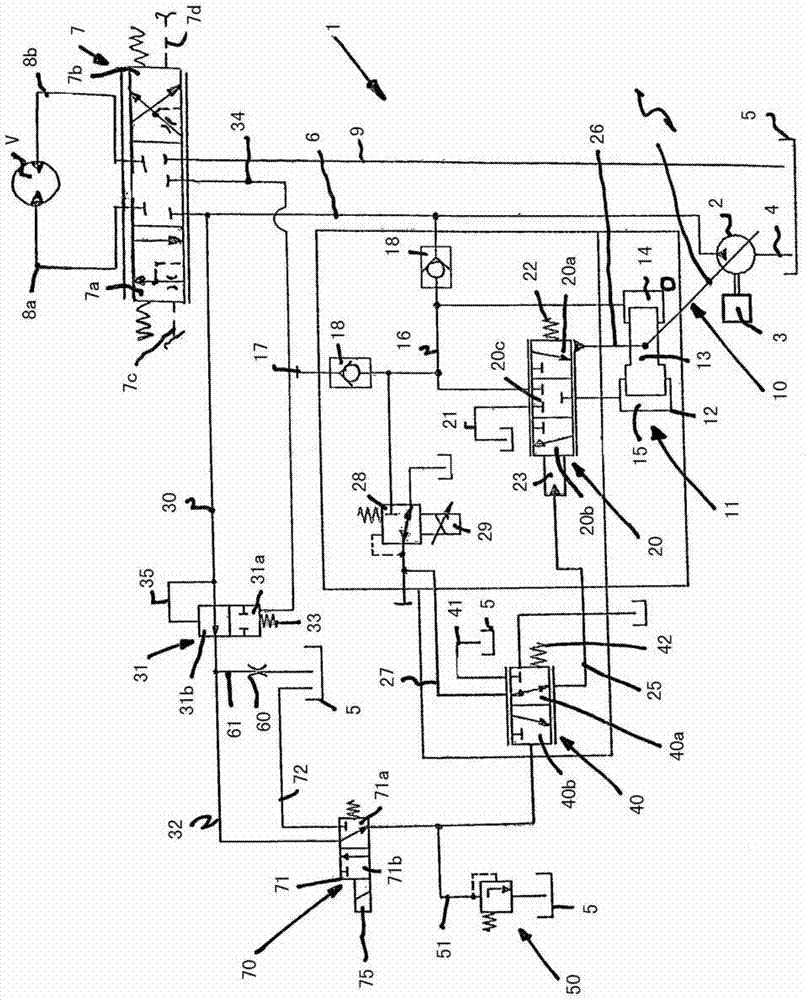

[0029] exist figure 1 A circuit diagram of a load-sensing regulated drive system 1 according to the present invention is shown in . The drive system 1 is used, for example, in mobile work machines, preferably excavators or ground vehicles.

[0030] The drive system 1 has a pump 2 with an adjustable delivery volume flow, which is operated in an open circuit and is in drive connection with a drive machine 3 , for example an internal combustion engine, for drive. The pump 2 is connected on the suction side to a container 5 by means of a line 4 and delivers pressure medium into a delivery line 6 .

[0031] In order to control one or more consumers V, a control valve 7 is provided in each case, which is designed as a directional valve that throttles in the middle position.

[0032] The control valves 7 are connected to the delivery line 6 , a container line 9 and pressure medium lines 8 a , 8 b leading to consumers V in each case. When the control valve 7 is actuated, the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com