Method for activating and adjusting mineralized bubbles in vulcanizing flotation process of copper oxide ores

A technology of mineralized foam and flotation process, applied in the direction of flotation, solid separation, etc., can solve the problem of no activator and mineralized foam adjuster used together, avoid copper metal loss, reduce volume and water content, The effect of easy production operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The properties of the original copper oxide ore sample are (mass percentage): Cu: 1.54%, CaO: 27.88%, MgO: 3.79%, Al 2 o 3 : 1.36%, SiO 2 : 29.87%, Fe: 2.96%, copper oxidation rate 88.40%, copper binding rate: 15.47%.

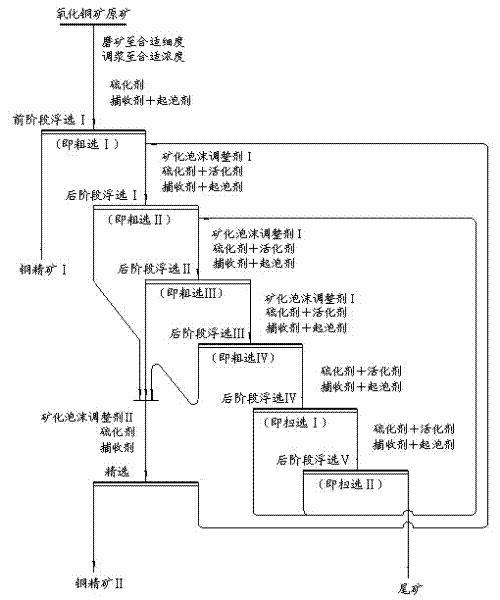

[0030] Including pre-stage flotation, post-stage flotation, and selection, the pre-stage flotation includes a section of roughing, a total of 1 segment; the post-stage flotation includes roughing and sweeping after the previous stage flotation , a total of 5 subsections, and a total of 1 subsection for the selection, specifically through the following steps:

[0031] A. The copper oxide ore is wet-ground until the mass of powder particles with a fineness of less than 74 μm accounts for 75%, and then the slurry is adjusted to a mass concentration of 32%;

[0032] B. Carry out the previous stage flotation of the pulp obtained in step A, add sodium sulfide 1500g / t, add butyl xanthate 80g / t, and add No. 2 oil 20g / t in the subsection of the previous stag...

Embodiment 2

[0039] The properties of copper oxide ore raw ore samples are (mass percentage): copper 1.0%-2.0%, copper oxidation rate 60%-80%, copper binding rate 6%-20%, CaO: 10-30%, MgO : 10~30%, binding rate: 16.21%.

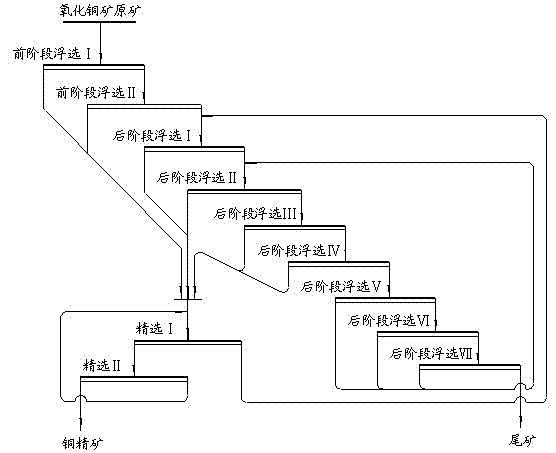

[0040] Including pre-stage flotation, post-stage flotation, and selection, the pre-stage flotation includes one-stage rough selection and two-stage rough selection, a total of 2 subsections; the post-stage flotation includes Rough selection and scanning, a total of 7 sub-sections, a total of 2 sub-sections of the selection, specifically through the following steps:

[0041] A. Wet-grind the copper oxide ore until the mass of powder particles with a fineness of less than 74 μm accounts for 65%, and then adjust the slurry to a slurry with a mass concentration of 28%;

[0042] B. Carry out the previous stage flotation with the pulp obtained in step A, add sodium hydrosulfide and sodium polysulfide 1400g / t in the first subsection of the previous stage flotation, add butyl ...

Embodiment 3

[0051] The properties of copper oxide ore raw ore samples are (mass percentage): copper 0.6%-1.2%, copper oxidation rate 60%-80%, copper binding rate 6%-20%, CaO: 10-20%, MgO : 10~15%, Al 2 o 3 : 5~10%.

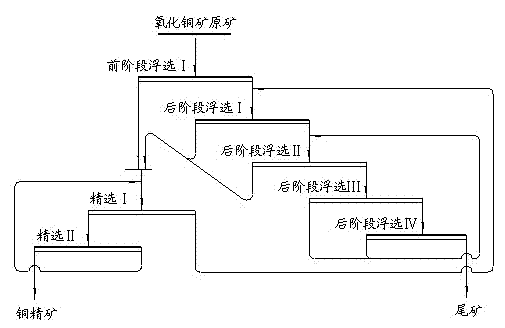

[0052] Including pre-stage flotation, post-stage flotation, and selection, the pre-stage flotation includes a section of roughing, a total of 1 segment; the post-stage flotation includes roughing and sweeping after the previous stage flotation , a total of 4 subsections, the selection of a total of 2 subsections, specifically through the following steps:

[0053] A. Wet-grind the copper oxide ore until the powder particles with a fineness of less than 74 μm account for 85% of the mass, and then adjust the slurry to a pulp with a mass concentration of 20%;

[0054] B. Carry out the previous stage flotation with the pulp obtained in step A, add sodium hydrosulfide 800g / t in the subsection of the previous stage flotation, add butyl xanthate 100g / t and No. 2 oil 40g / t;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com