System and method for processing of minerals containing the lanthanide series and production of rare earth oxides

一种稀土氧化物、镧系元素的技术,应用在稀土金属氧化物/氢氧化物、化学仪器和方法、稀土金属化合物等方向,能够解决缺少不同元件和操作步骤等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

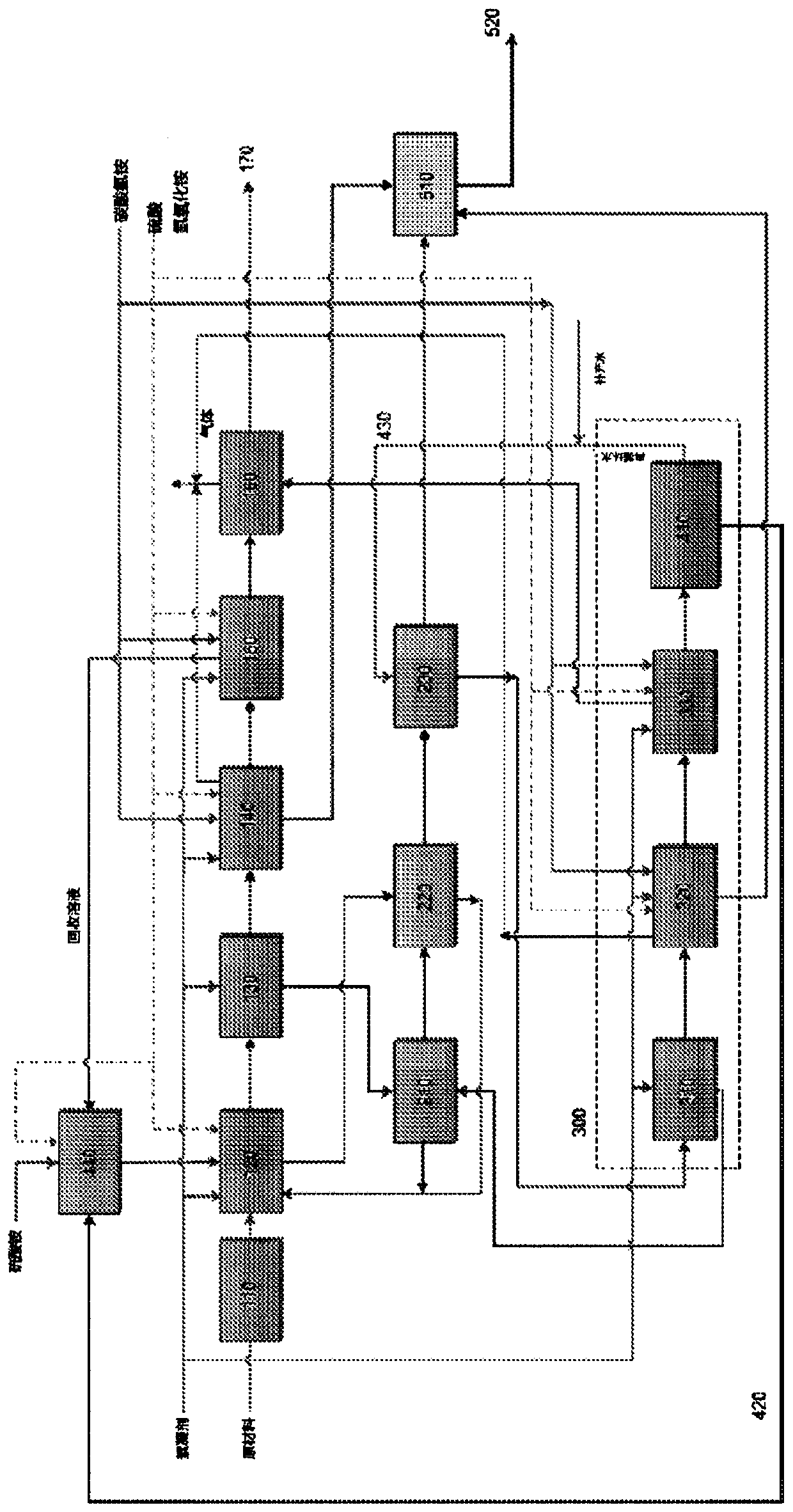

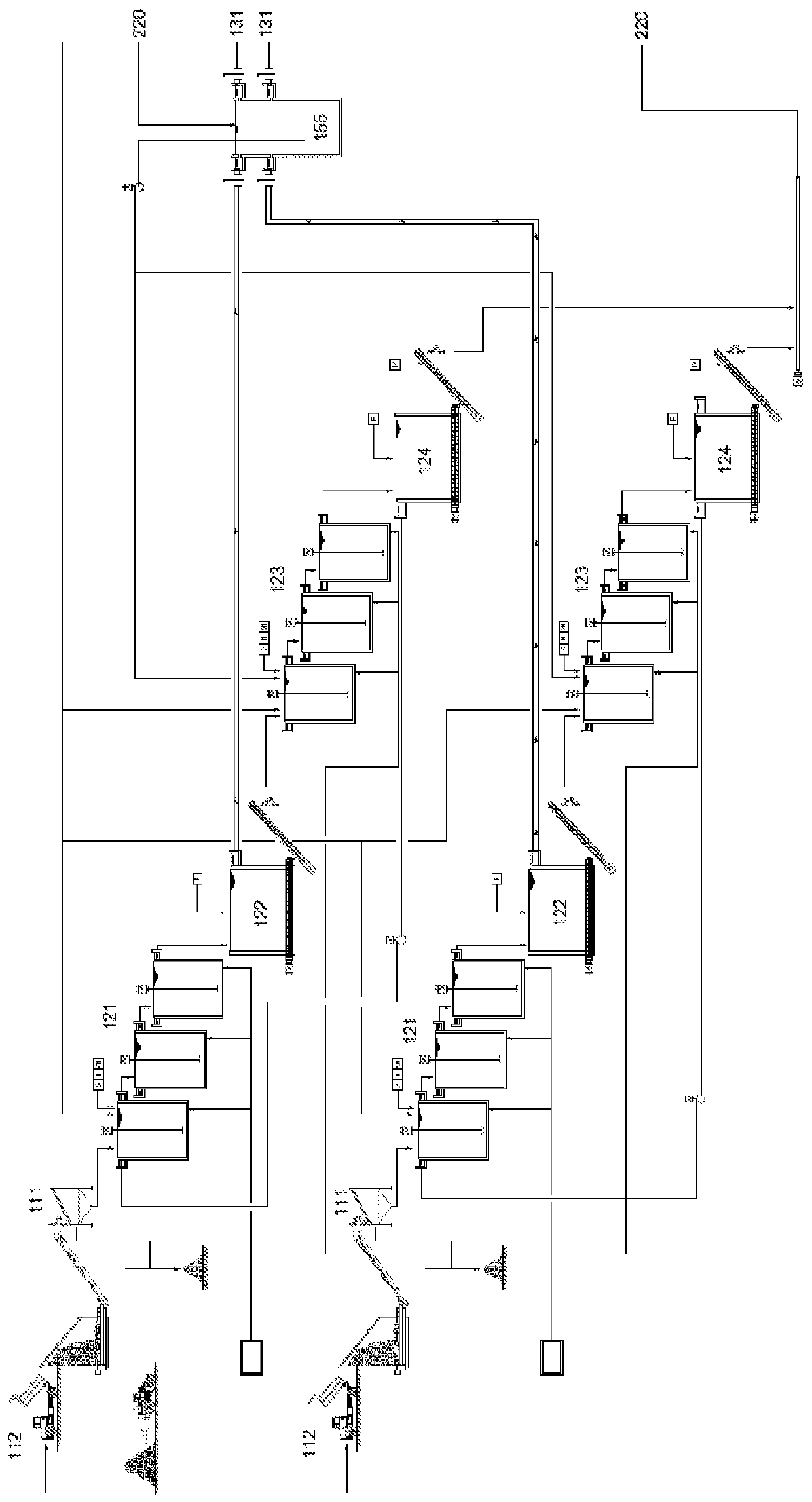

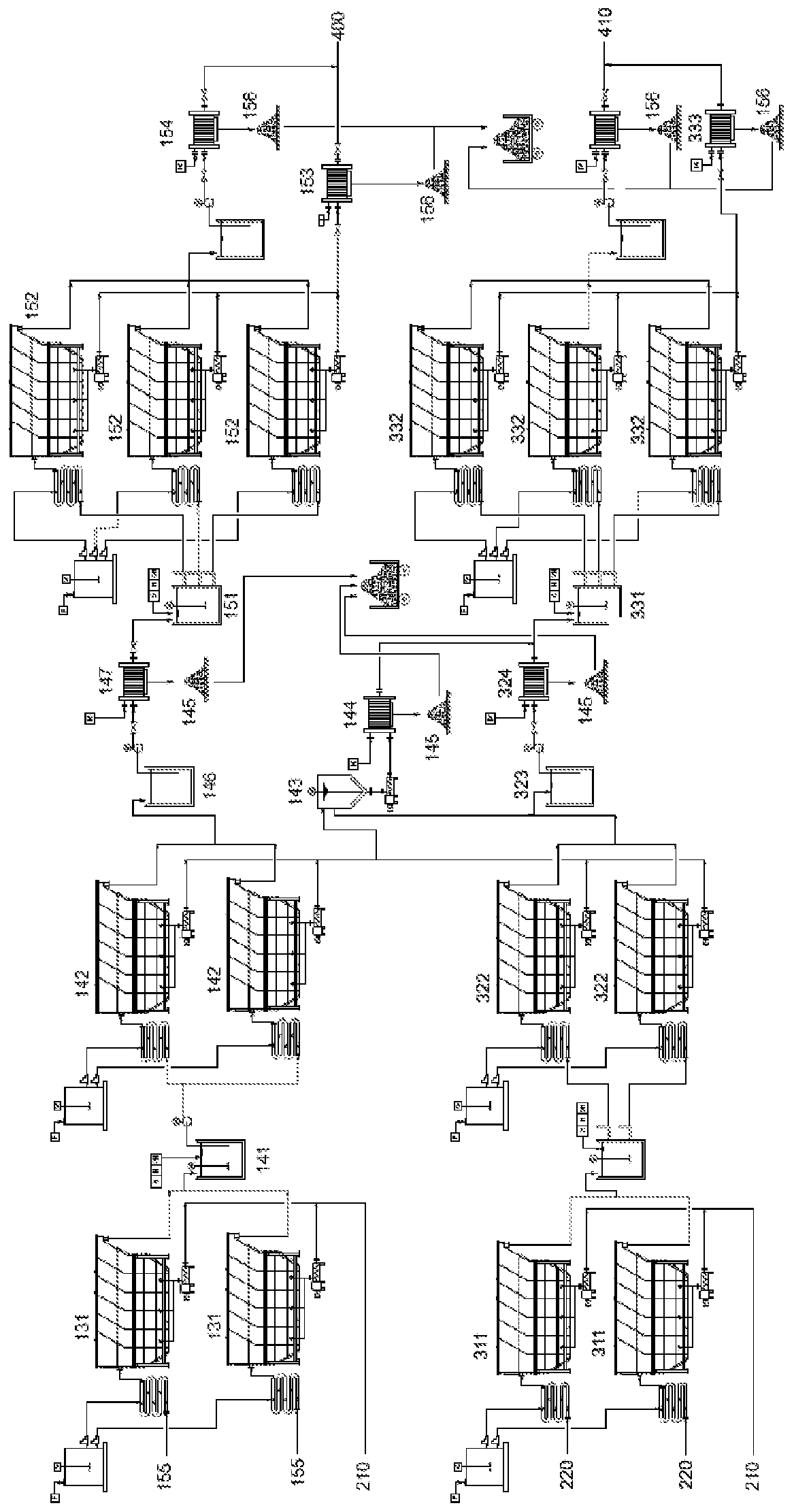

[0034] Such as Figure 1-Figure 5 As shown, the present invention relates to systems and methods for processing lanthanide minerals and production of rare earth oxides that allow fully enclosed and continuous processing of the different materials and desorbents involved in the process, thus increasing extraction efficiency and avoiding environmental Danger.

[0035] Method of the present invention comprises steps:

[0036] a) receipt and handling of raw materials (110);

[0037] b) desorbing the product of interest (120) through multiple mixing and reaction stages in which the raw material is contacted counter-currently with a stream of desorbent solution;

[0038] c) separating fine solids (130);

[0039] d) precipitating secondary minerals by using the first reaction solution (140);

[0040] e) Precipitating the rare earth carbonate (150) by using the second reaction solution; and

[0041] f) drying and calcining said carbonates to obtain rare earth oxides;

[0042] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com