Production of magnetic refrigerant material by ferro-manganese mixture

A technology of magnetic refrigeration materials and ferromanganese concretions, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of low grade and no mining value, and achieve simple preparation process, broaden possibilities, and rich sources of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

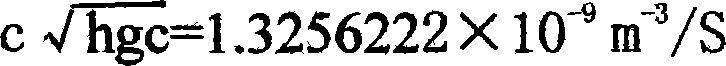

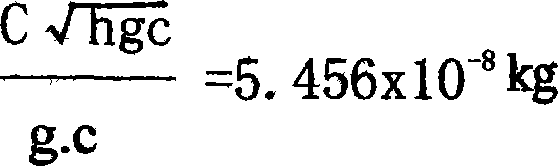

[0012] Take 10 kg of iron-manganese nodule secondary ore or oceanic polymetallic nodule secondary ore, add dilute nitric acid to dissolve, control the pH value to 3-4, then add 10 kg of gadolinium gallium garnet powder, mix evenly, and wait for the pH value to increase After reaching a slightly acidic pH of about 6.5, then use excess tartaric acid aqueous solution to fully mix and dehydrate through a centrifugal dehydrator. The dehydrated material is heated in the air at 900-1000°C. After that, it becomes a magnetic refrigeration material. During the above-mentioned whole reaction process, some non-magnetic gallium ions are replaced by magnetic iron ions, and due to the super exchange between Fe ions and Gd ions, the local magnetic moment is ordered to form a magnetic nano-cluster material. The effective working temperature range of the magnetic refrigeration material is 15k-40k.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com