Method for controlling mine heavy metal flushing pollution by using humification product

A pollution control and humification technology, applied in the restoration of polluted soil and the treatment of biological organic parts, can solve the problems of secondary pollution, limited passivation effect of heavy metals, complicated phytoremediation process, etc., and reduce carbon emissions , Repair the pollution of mine flushing and realize the effect of harmlessness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Promoting the generation of polar humic groups

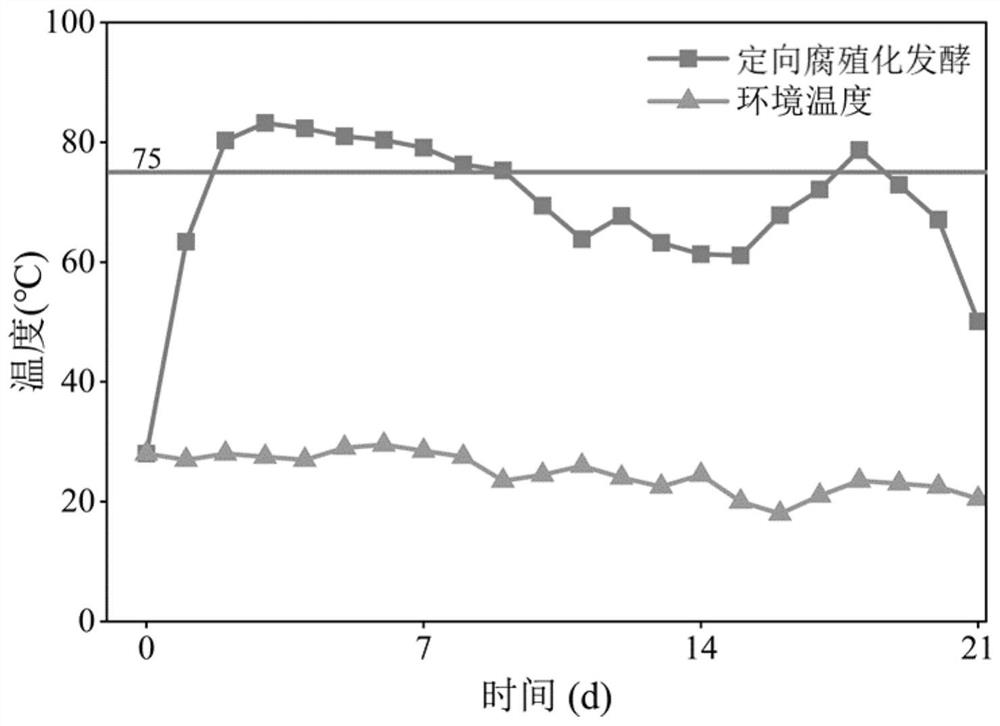

[0034] Using ultra-high temperature aerobic fermentation, the sludge and extreme thermophilic bacteria (Thermus sp.) are mixed and fermented. The initial moisture content is controlled at 53.7%, and the organic matter content is 62.4%. The highest fermentation temperature is 83.2°C, and the fermentation time is 14 days , and then add 20wt% biochar for secondary fermentation, the fermentation time is 7d, the time for maintaining ≥75°C is 9d, and the total fermentation time is 21d, figure 1 For the change of fermentation temperature.

[0035] 2. Determination of the content of polar functional groups in humification products

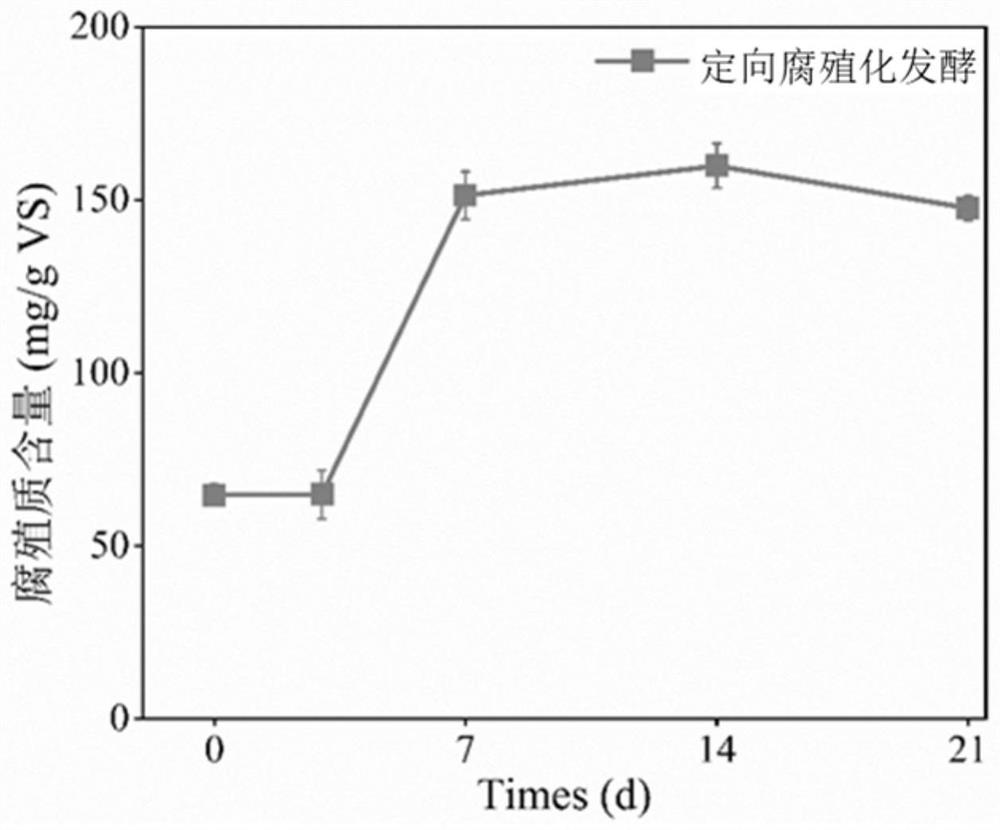

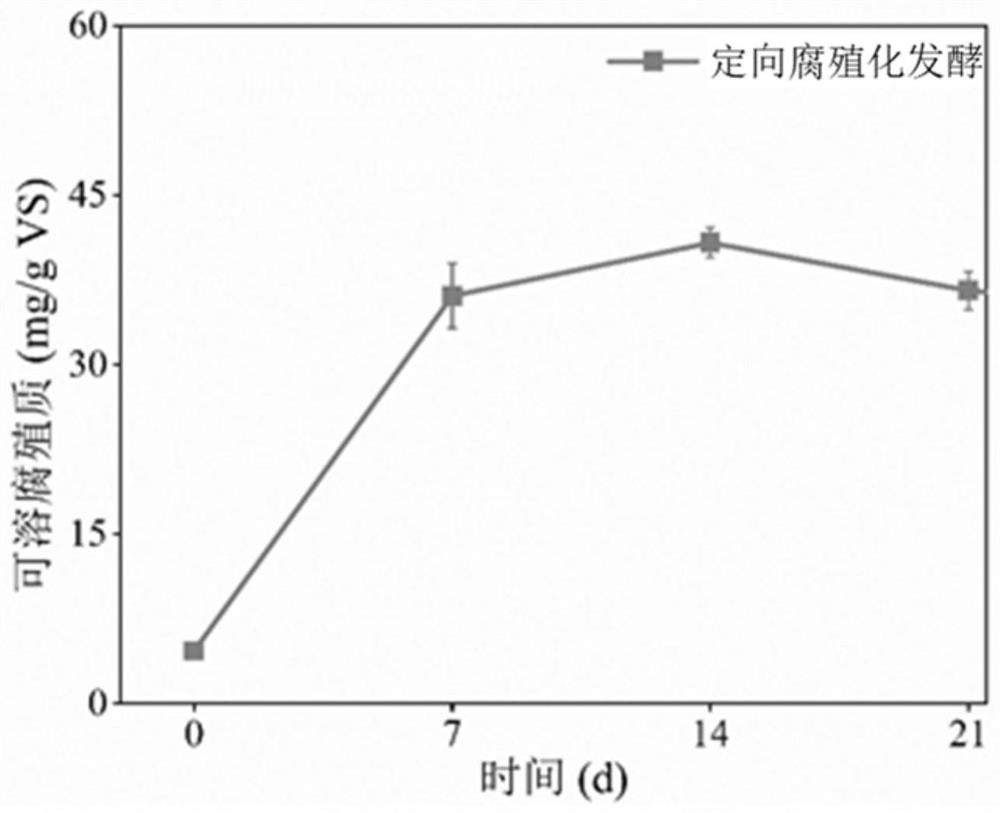

[0036] Before fermentation, the sludge humus content (characterized by the humic carbon content) is 64.7mg / g VS, and the content of the humus material of the decomposed material in step 1 (characterized by the humic carbon content) is 147.6mg / g VS, reaching the sludge humic content requirement Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com