Preparation and application of carbon-coated iron oxide of high-mediation oxalic acid reduced chromium

An iron oxide, carbon coating technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, chemical/physical process, etc., can solve problems such as iron ion leaching, achieve low cost, Simple preparation method and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

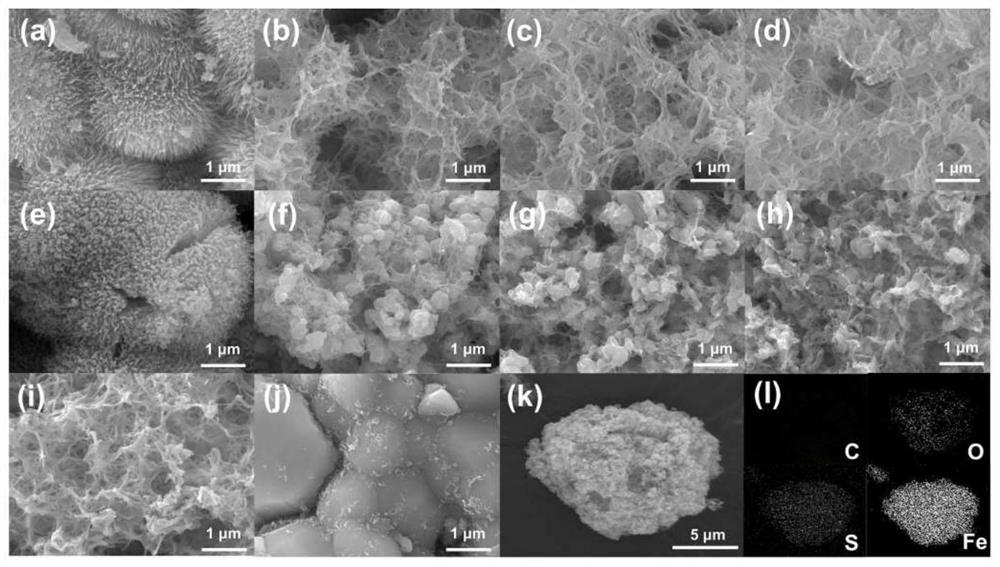

[0029] This example is used to illustrate the morphology characterization of carbon-coated iron oxides.

[0030] The method comprises the following steps: (1) adding a certain amount of Acidithiobacillus ferrooxidans cell suspension to 200 mL of deionized water with a pH of 2.00 containing 15 g of ferrous sulfate heptahydrate and 0, 1, 1.5, and 2.0 g of polyvinyl alcohol;

[0031] (2) After culturing in a constant temperature shaking shaker at 200 rpm and 30°C for 72 hours, simply filter, dry and grind to obtain different PVA-doped and modified Shi formula minerals;

[0032] (3) The Shi-type minerals obtained with different PVA doping modifications were calcined in a tube furnace for 2 hours, taken out at room temperature, and sealed with nitrogen gas for storage.

[0033] Further, the different PVA-doped and modified Shi-type minerals obtained in step (3) were calcined in a tube furnace at 500, 700, and 900°C for 2 hours, the calcining conditions were argon atmosphere, and th...

Embodiment 2

[0036] This example is used to illustrate the structural characterization of carbon-coated iron oxides.

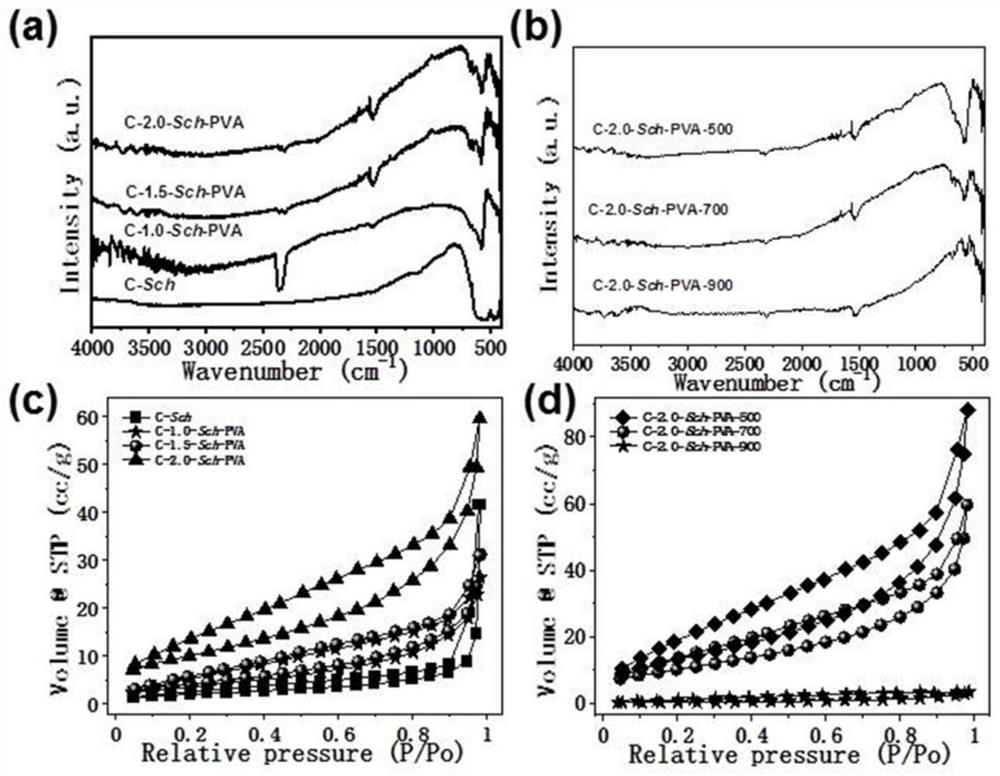

[0037] Such as figure 2 (a), PVA-modified Shi minerals retain their original phase composition and crystal structure. Such as figure 2 (b), the functional groups of the calcined Sch and modified Sch are significantly reduced. Including -OH characteristic band becomes weaker, SO 4 2- The characteristic bands disappear due to the evaporation of elemental sulfur. Calcined Sch-PVA has obvious Fe 2+ -O 2- group, with the increase of calcination temperature, Fe 2+ -O 2-The group bands gradually disappear. This can be attributed to the enhanced reduction of iron in PVA-modified Shi-type minerals at higher calcination temperatures.

[0038] Such as image 3 As shown in (c), the specific surface areas of C-Sch, C-1.0-Sch-PVA, C-1.5-Sch-PVA and C-2.0-Sch-PVA are 7.768, 13.890, 16.067 and 36.962m respectively 2 g -1 . The specific surface area of PVA modified sampl...

Embodiment 3

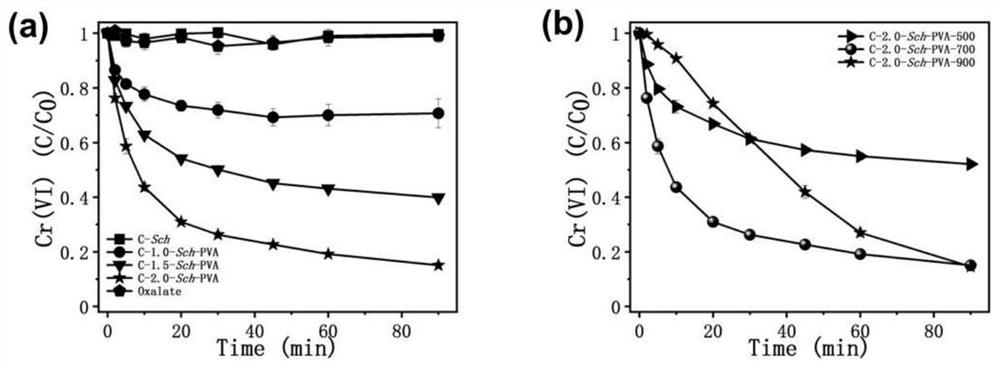

[0040] This example is used to illustrate the effect of carbon-coated iron oxides modified by pyrolysis with different PVA contents and different temperatures on mediating the reduction of Cr(VI) with oxalic acid.

[0041] Such as image 3 As shown, the modified Shi-type minerals with different PVA content after calcination will produce obvious differences when mediating OA to remove Cr(VI). Individual OA, C-Sch, C-1.0-Sch-PVA, C-1.5 -Sch-PVA, C-2.0-Sch-PVA within 90min, mediated oxalic acid removal efficiency of Cr(VI) was 1.0%, 0.4%, 29.3%, 60.2% and 84.9%. Those modified with high PVA content will retain more carbonaceous framework after calcination. The presence of aromatic structures in carbon-coated iron oxides produced at a calcination temperature of 700 °C facilitates electron transfer, and more oxygen-containing groups are beneficial to drive redox reactions in Cr(VI) and OA systems. The high specific surface area of C-2.0-Sch-PVA provided more functional sites fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com