High-efficiency filter device and wastewater treatment method for beneficiation wastewater treatment

A high-efficiency filtration technology for mineral processing wastewater, which is applied to loose filter material filters, filtration separation, separation methods, etc., can solve the problems of increasing sedimentation sludge containing heavy metals, poor sedimentation performance of mineral processing wastewater, and failure to achieve removal effects. Achieve the effect of improving sedimentation uniformity, low price and fast filtration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The high-efficiency filter device of the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

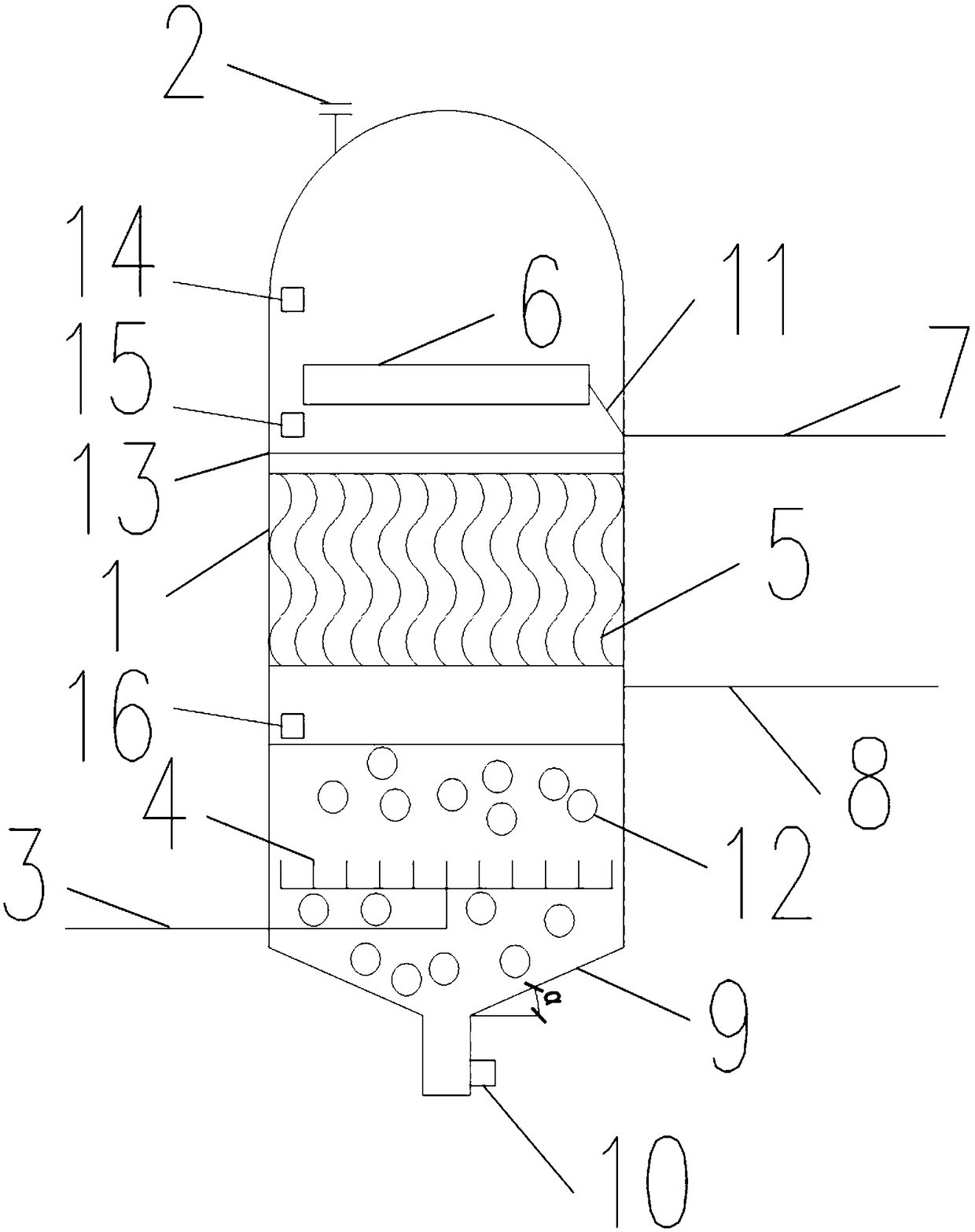

[0044] Such as figure 1 As shown, the embodiment of the high-efficiency filter device includes a circular tank body 1 with an outer diameter of 3500 mm and a stainless steel plate with a thickness of 3 mm. The total height of the tank body is 6000 mm. The lower part is a shallow slope-shaped slag discharge hopper 9 with a slope of α=15°, and a slag discharge valve 10 is arranged at the lower end of the slag discharge hopper.

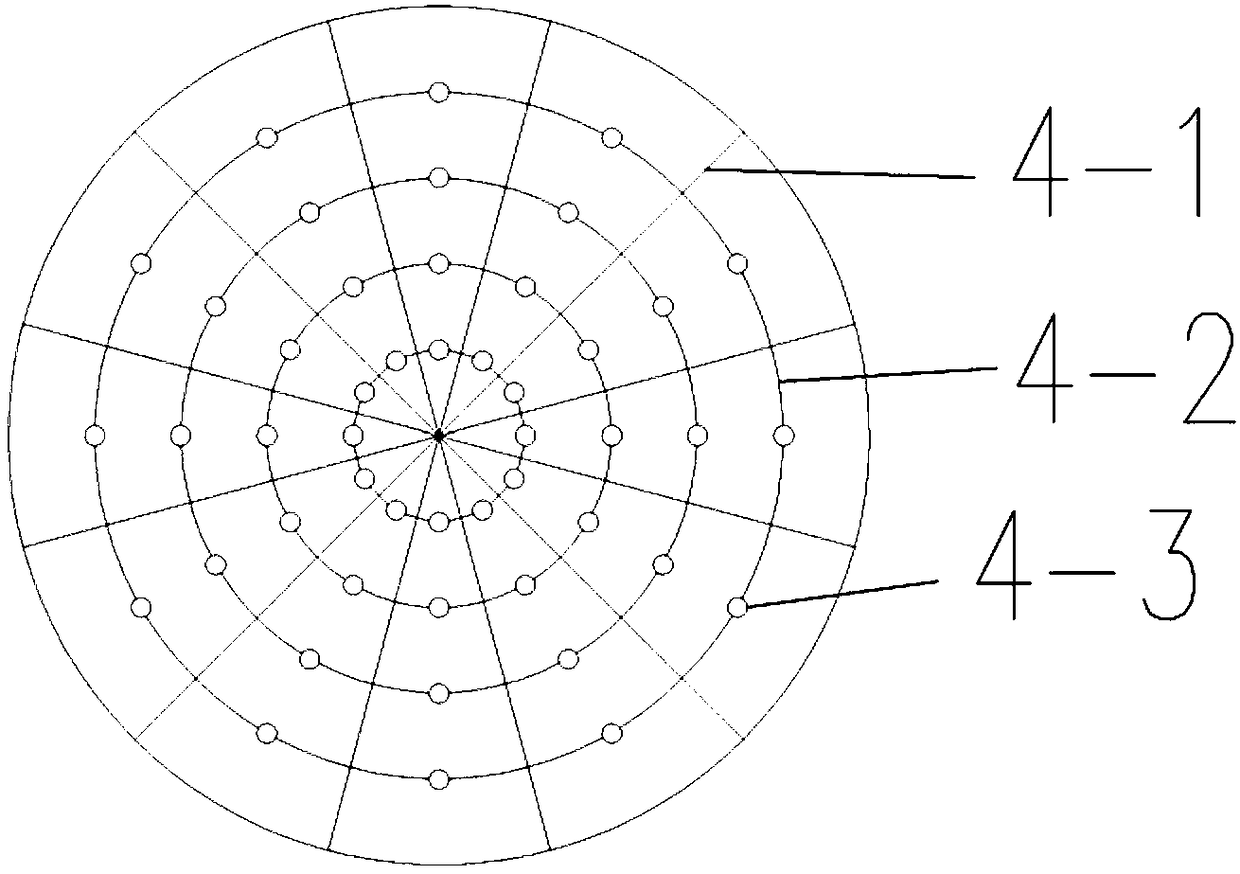

[0045] A waste water supply device is arranged on the top of the slag discharge hopper, and the waste water supply device is composed of a water inlet pipe 3 whose front end passes through the tank body and a water distribution device 4 connected with the water inlet pipe. water distribution device such as figure 2 As shown, it includes water distribution main pipe 4-2, water distribution b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com