Tin reclaiming method for fine-grain and low-grade secondary mineral tailings

A recovery method and low-grade technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as poor dissociation degree of tin monomer, complex and difficult tin beneficiation, and low recovery rate, so as to promote Separation, significant economic and social significance, and the effect of increasing recycling rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

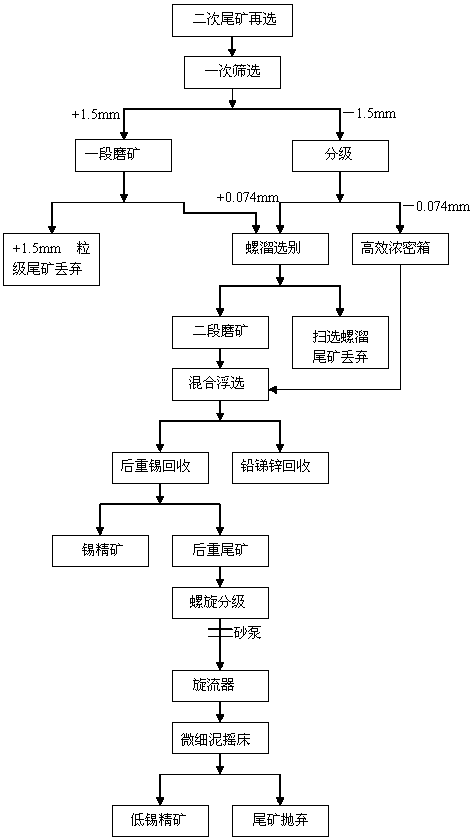

Method used

Image

Examples

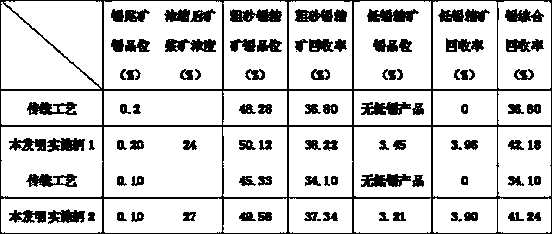

Embodiment 1

[0027] Example 1: The raw material is secondary tailings with a particle size of -0.074mm and a grade of 0.20% tin.

[0028] (1) Treatment of re-throwing tailings before secondary tailings:

[0029] A. Put the secondary tailings into the vibrating sieve for classification and screening, and the +1.5mm particle size product will enter the next grinding process, -1.5—0.074mm particle size product will enter the sorting operation, and -0.074mm will enter the high-efficiency inclined plate thickening box;

[0030] B. Transfer the +1.5mm tailings to the primary grinding process for coarse grinding, and grind to 0.074mm, accounting for 30%. The grinding products are screened by the vibrating screen, and the +1.5mm tailings are directly thrown away, and -1.5mm The particle size enters the sweeping screw chute operation;

[0031] C. Put the -1.5mm particle size product under the vibrating screen into the roughing screw chute to obtain the wool concentrate product suitable for the sel...

Embodiment 2

[0040] Example 2: The raw material is secondary tailings with a particle size of -0.068mm and a grade of 0.25% tin.

[0041] (1) Treatment of re-throwing tailings before secondary tailings:

[0042] A. Put the secondary tailings into the vibrating sieve for classification and screening to obtain +1.5mm and -1.5mm products; +1.5mm enters into B, and -1.5mm is classified to obtain +0.074mm into coarse Selecting snails and sorting, -0.074mm enters the high-efficiency inclined plate thickening box;

[0043] B. The tailings with a particle size of +1.5mm are transferred to the first-stage grinding process for coarse grinding, and the ground to a particle size of 0.074mm accounts for 32%; the grinding products are screened, and the tailings with a particle size of +1.5mm are directly thrown away; The rougher snail tailings are merged and enter the sweeping snail separation;

[0044] C. Combine the rough-separated spiral chute tailings product and the coarsely ground -1.5mm grain g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com