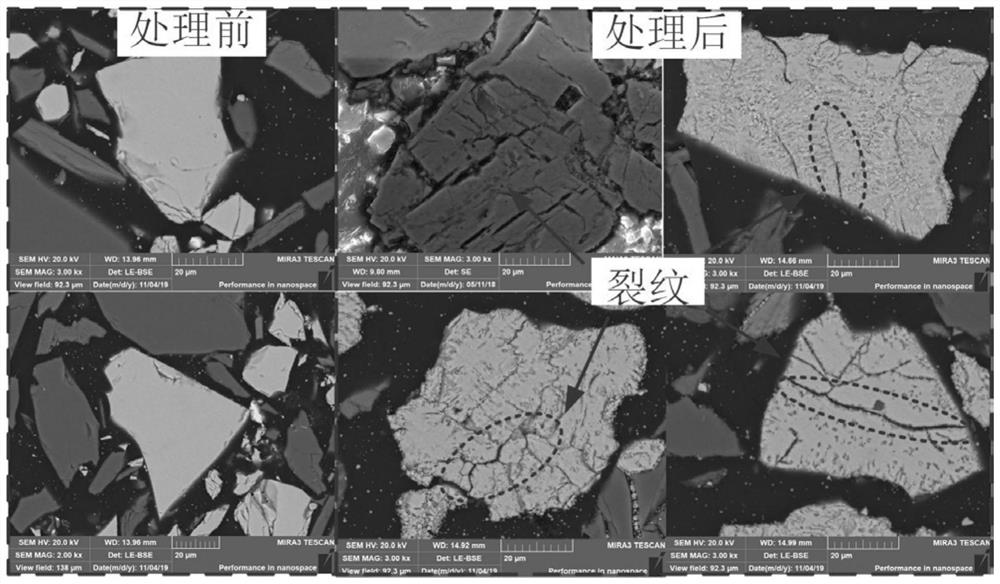

Method for strengthening reduction roasting based on heating cracking of iron-containing material

A material and roasting technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., to reduce apparent activation energy, increase reactive sites, and increase reaction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The iron-bearing material is a complex iron ore ore with an iron grade of TFe 33.56% and SiO in mass percentage 2 44.95%;

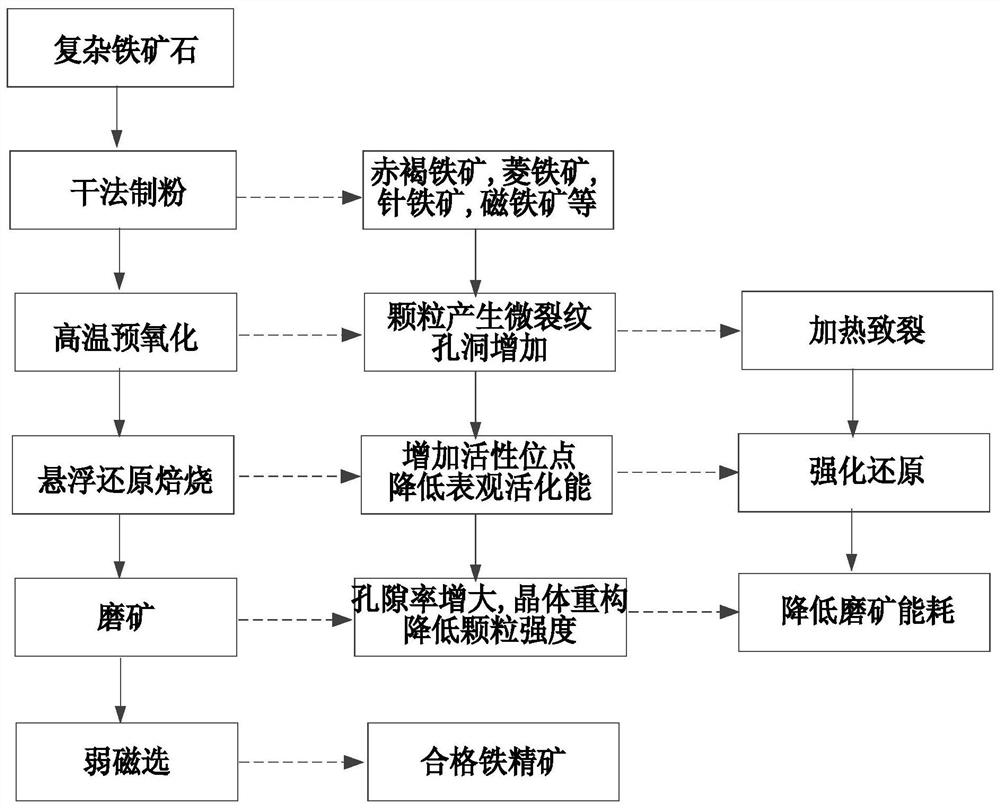

[0058] The process is like figure 2 Shown

[0059] Crush the iron-containing material to a particle size of 2-15mm, and then grind the ore to a particle size of -0.074mm, which accounts for 35% of the total mass, to make mineral powder;

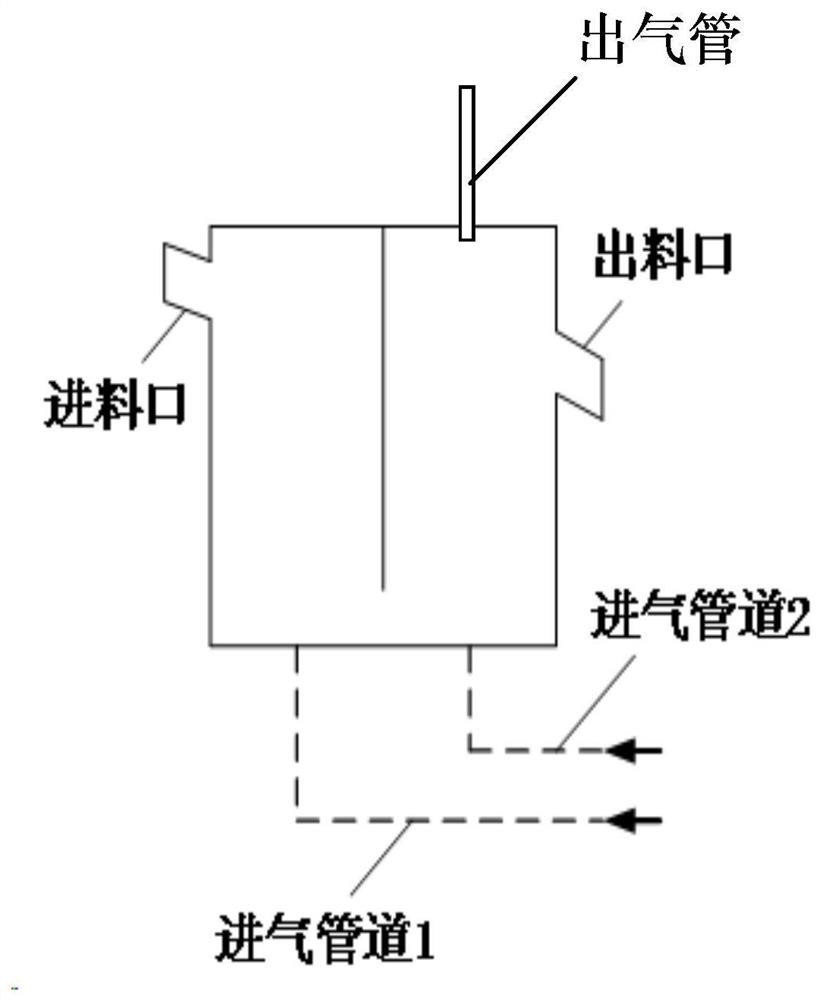

[0060] Adopt a pre-oxidation roaster with a burner and an air inlet at the bottom. The lower part of the pre-oxidation roaster is provided with a feed inlet, the upper part is connected to the cyclone separator through a material channel, and the exhaust port of the cyclone separator is connected to the induced draft fan through a pipe; Pass natural gas into the burner to produce combustion flue gas and pass it into the pre-oxidation roaster. At the same time, under the condition of starting the induced draft fan, pass air into the pre-oxidation roaster and remove the ore powder from the lower part of the pre-oxidation...

Embodiment 2

[0067] The iron-bearing material is a complex iron ore ore, with an iron grade of TFe 38.7% and containing SiO by mass percentage 2 41.4%;

[0068] The method is the same as in Example 1, the difference is:

[0069] (1) The part that is ground to a particle size of -0.074mm accounts for 40% of the total mass;

[0070] (2) The pre-oxidation roasting temperature is 820℃; the residence time of the solid materials in the pre-oxidation roasting furnace is 4 min;

[0071] (3) The reduction roasting temperature is 530℃; the amount of reducing gas is the CO / H required for the complete reaction of the reduction roasting 2 1:2 times the theoretical amount; the volume flow ratio of nitrogen and reducing gas in the regenerative reduction roaster is 3:1; the residence time of the solid materials in the regenerative reduction roaster is 35min;

[0072] (4) Cool down to 210°C to obtain cooled and reduced materials; the residence time of the reduced materials in the primary cooling cyclone is 2.5 min;...

Embodiment 3

[0075] The iron-bearing material is a complex iron ore ore, with an iron grade of TFe 29.67%, containing SiO by mass percentage 2 49.84%;

[0076] The method is the same as in Example 1, the difference is:

[0077] (1) The part that is ground to a particle size of -0.074mm accounts for 50% of the total mass;

[0078] (2) The pre-oxidation roasting temperature is 830℃; the residence time of the solid materials in the pre-oxidation roasting furnace is 6 min;

[0079] (3) The reduction roasting temperature is 550℃; the amount of reducing gas is the CO / H required for the complete reaction of the reduction roasting 2 1.3 times the theoretical amount; the volume flow ratio of nitrogen and reducing gas in the regenerative reduction roaster is 2.5:1; the residence time of solid materials in the regenerative reduction roaster is 20min;

[0080] (4) Cool down to 250°C to obtain cooled and reduced materials; the residence time of the reduced materials in the primary cooling cyclone is 5 min; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com