Method for producing sponge iron by reducing pyrites through coal synthesis gas in shaft furnace

A coal-to-synthesis gas and pyrite technology, applied in shaft furnaces, furnaces, furnace types, etc., can solve the problems of low pyrite quality, low pyrite extraction rate, immature equipment, etc., and achieve large gas The effect of utilization rate, large industrial application value, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of sponge iron:

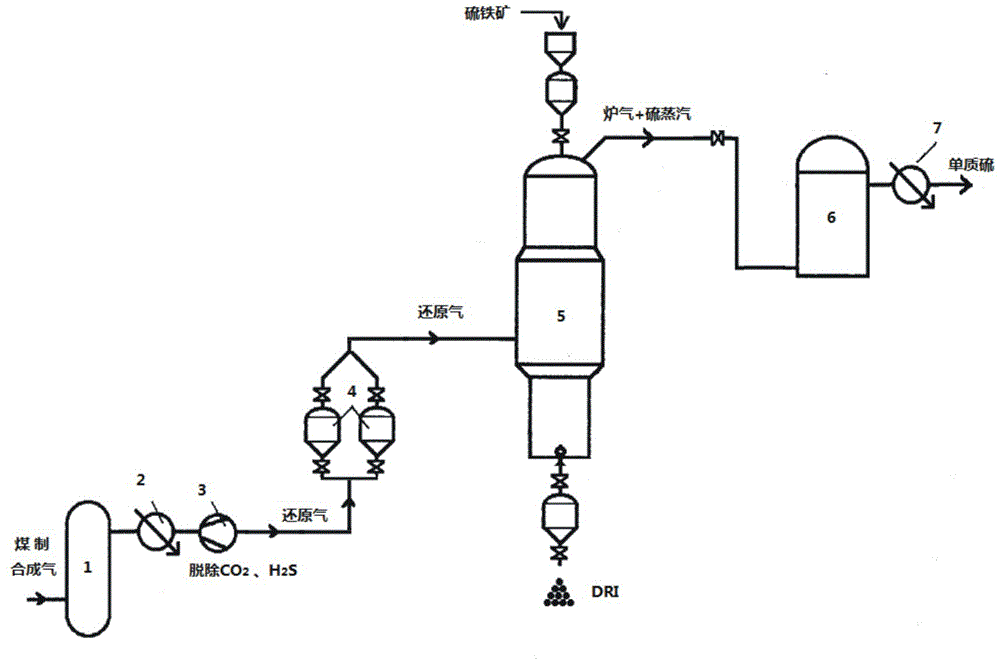

[0027] combine figure 1 As shown, the coal-to-synthesis gas is passed through the water-gas shift device 1 to convert H 2 After adjusting the ratio with CO to 1.73 (volume ratio), it enters the NHD gas purification equipment 2 to remove acid gas components: hydrogen sulfide and carbon dioxide, and obtain a high-pressure reducing gas with a total content of carbon monoxide and hydrogen of 95.7% (volume ratio). After reducing the pressure of the reducing gas to 0.7MPa, it is transported to the heating furnace 4 through the steam turbine 3, and after being heated to 927°C, the reducing gas and pyrite with a sulfur content of 27.8% and iron content of 43.6 are respectively input into the shaft furnace 5. In the moving bed of the furnace, the reducing gas reduces the pyrite to sponge iron, and the sulfur steam and the furnace gas pass through the dedusting cooler 6 to remove the mineral dust, and after cooling down to 400°C, the sulfur is conde...

Embodiment 2

[0029] combine figure 1 As shown, the coal-to-synthesis gas is passed through the water-gas shift device 1 to convert H 2 Adjust the ratio with CO to 2.15 (volume ratio) and enter NHD gas purification equipment 2 to remove acid gas components: hydrogen sulfide and carbon dioxide, and obtain high-pressure reducing gas with carbon monoxide and hydrogen content of 96.1% (volume ratio). After reducing the pressure of the reducing gas to 0.65MPa, it is transported to the heating furnace 4 through the steam turbine 3, and after being heated to 950°C, the reducing gas and pyrite with a sulfur content of 31.2% and iron content of 40.8 are respectively input into the shaft furnace 5. In the moving bed of the furnace, the reducing gas reduces the pyrite to sponge iron, and the sulfur steam and the furnace gas pass through the dedusting cooler 6 to remove the mineral dust, and after cooling down to 400°C, the sulfur is condensed and recovered through the water film desulfurization and de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com