Method of preparing battery grade lithium hydroxide by directly electrolyzing lithium chloride

A lithium hydroxide and lithium chloride technology, applied in the electrolysis process, electrolysis components and other directions, can solve the problems of incompatibility with lithium resource utilization and environmental protection, high impurity content of lithium hydroxide, low purity of lithium hydroxide, etc. The method is safe and reliable, with high purity, and realizes the effect of circular economy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The method for preparing battery-grade lithium hydroxide by direct electrolysis of lithium chloride of the present invention comprises the steps of:

[0058] A, Lithium chloride solution is carried out refined treatment, obtains refined Lithium chloride solution, and refined Lithium chloride solution meets following technical index:

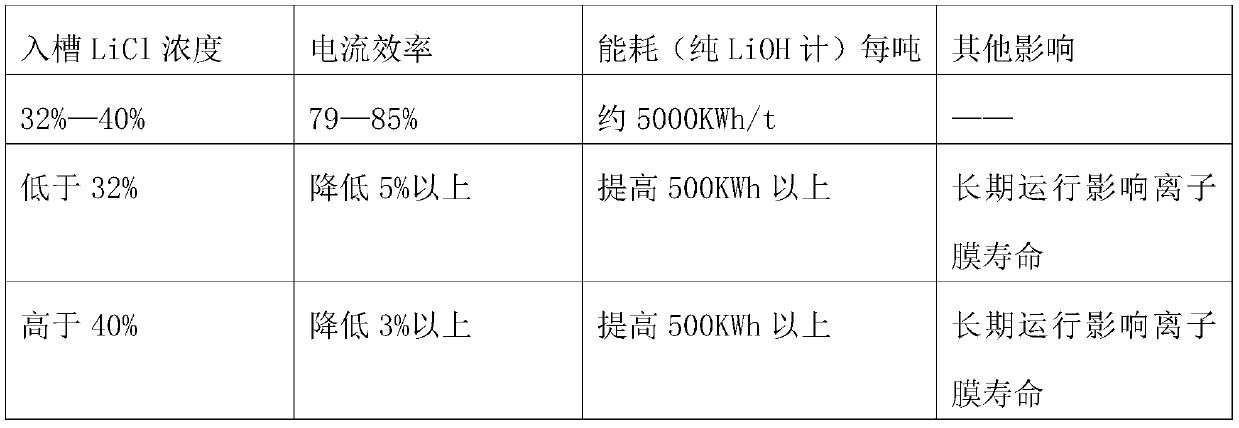

[0059] (1) the mass percentage concentration of lithium chloride is 32%-40%;

[0060] (2) the content sum of calcium ion and magnesium ion in lithium chloride solution is 20-50ppb;

[0061] (3) The content of sodium chloride in the lithium chloride solution is not higher than 500ppm;

[0062] (4) the content sum of ferrous ion and ferric ion in lithium chloride solution is 50-100ppb;

[0063] (5) sulfate ion content is 4-7g / L in lithium chloride solution;

[0064] (6) aluminum ion content is 100-200ppb in lithium chloride solution;

[0065] (7) barium ion content is 100-200ppb in the lithium chloride solution;

[0066] (8) iodide ion ...

Embodiment 2

[0084] The method for preparing battery-grade lithium hydroxide by direct electrolysis of lithium chloride of the present invention comprises the steps of:

[0085] A, Lithium chloride solution is carried out refined treatment, obtains refined Lithium chloride solution, and refined Lithium chloride solution meets following technical index:

[0086] (1) The mass percent concentration of lithium chloride is 33% or 35% or 37% or 39%;

[0087] (2) the content sum of calcium ion and magnesium ion in lithium chloride solution is 20-50ppb;

[0088] (3) The content of sodium chloride in the lithium chloride solution is not higher than 500ppm;

[0089] (4) the content sum of ferrous ion and ferric ion in lithium chloride solution is 50-100ppb;

[0090] (5) sulfate ion content is 4-7g / L in lithium chloride solution;

[0091] (6) aluminum ion content is 100-200ppb in lithium chloride solution;

[0092] (7) barium ion content is 100-200ppb in the lithium chloride solution;

[0093] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com