Method and system for producing gasoline and propylene by integrating heavy oil catalytic cracking with oxygen-containing compound conversion

A heavy oil catalysis and catalytic cracking technology, used in the production of hydrocarbons from oxygen-containing organic compounds, chemical instruments and methods, and bulk chemical production, etc. To solve the problems of small quantity, etc., to achieve the effect of flexible product plan, improving gasoline quality and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

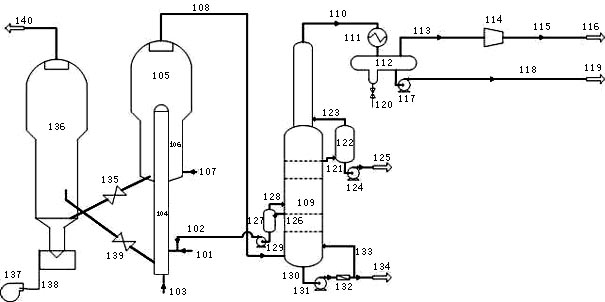

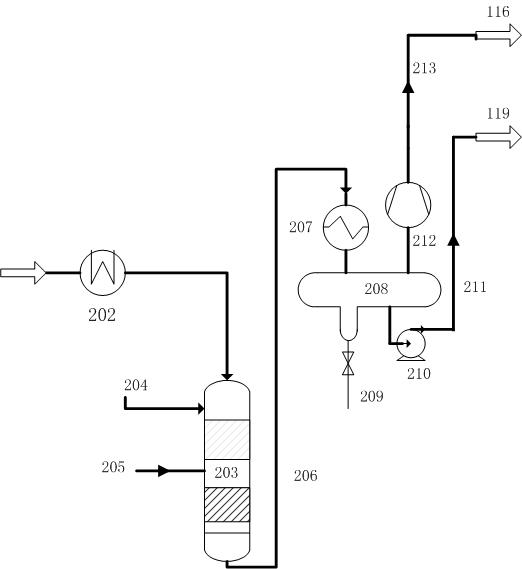

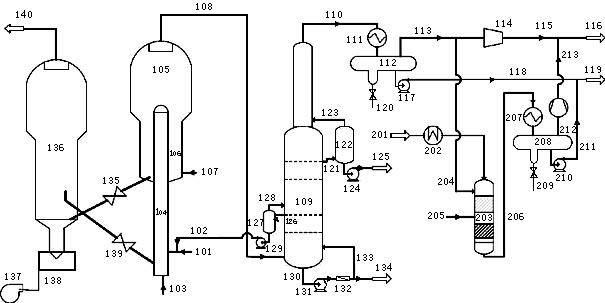

[0073] image 3 Schematic of the plant for the production of gasoline and propylene with integrated oxygenate conversion for heavy oil catalytic cracking. combine image 3 An embodiment of the integrated process of the heavy oil catalytic cracking and methanol conversion reactor of the present invention for only converting methanol is illustrated.

[0074] The operation of the original heavy oil catalytic cracking reaction regeneration system remains unchanged, as shown in Comparative Example 1.

[0075] The fresh raw material 201 of the oxygen-containing compound in the present invention is crude methanol (commercially available, containing 20% water by weight), and after being heated up to 200°C by the heat exchanger 202, it enters the fixed-bed conversion reactor group 203 and contacts with the special catalyst A, and the methanol The ratio of feed amount to catalytic cracking raw oil is 0.85, and the reactor group is a combination of 2-5 fixed bed reactors, so that whe...

Embodiment 2

[0081] image 3 Schematic of the plant for the production of gasoline and propylene with integrated oxygenate conversion for heavy oil catalytic cracking. combine image 3 It shows that according to the integrated process technology of the present invention, the methanol conversion reactor converts methanol, partially catalytic cracking rich gas and desulfurized dry gas integrated working conditions.

[0082] The operation of the original heavy oil catalytic cracking reaction regeneration system remains unchanged, as shown in Comparative Example 1.

[0083] The fresh raw material 201 for oxygenated compounds in the present invention is crude methanol (commercially available, containing 20% water by weight), and after being heated up to 300°C by the heat exchanger 202, it enters the fixed bed conversion reactor group 203 and contacts with the special catalyst B, and the methanol The ratio of feed amount to catalytic cracking raw oil is 0.5, and the reactor group is a combin...

Embodiment 3

[0090] image 3 Schematic of the plant for the production of gasoline and propylene with integrated oxygenate conversion for heavy oil catalytic cracking. combine image 3 It shows that according to the integrated process technology of the present invention, the methanol conversion reactor converts methanol, partially catalytic cracking rich gas and desulfurized dry gas integrated working conditions.

[0091] The operation of the original heavy oil catalytic cracking reaction regeneration system remains unchanged, as shown in the ratio of Example 1.

[0092]The fresh raw material 201 of the oxygen-containing compound in the present invention is crude methanol (commercially available, containing 20% water by weight), and after being heated to 300°C by the heat exchanger 202, it enters the fixed-bed conversion reactor group 203 and contacts with the special catalyst C, and the methanol The ratio of feed amount to catalytic cracking raw oil is 0.5, and the reactor group is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com